- Overview

- Recommended Products

Material Versatility and Enhanced Performance

Our gravity sand casting process accommodates a wide range of ferrous and non-ferrous alloys, including aluminum (A356, 319), ductile iron (65-45-12), and gray iron (Class 35). This versatility allows for material selection tailored to specific performance requirements. The gravity pouring method ensures dense, uniform metallurgical structure with minimal porosity, significantly enhancing mechanical properties. Typical aluminum castings achieve tensile strength of 230 MPa with 3% elongation, while our ductile iron components reach 450 MPa tensile strength with 12% elongation, providing exceptional impact resistance and durability under heavy load conditions.

Advanced Production Methodology

We employ state-of-the-art sand casting techniques using chemically-bonded molding systems (phenolic urethane, sodium silicate) that maintain dimensional stability during metal solidification. Our process begins with precision pattern making, followed by automated mold preparation and careful metal pouring control. The gradual filling of molds under gravity minimizes turbulence, preventing gas entrapment and oxidation defects. Post-casting, components undergo heat treatment (T6 for aluminum, annealing for iron) to optimize mechanical properties, followed by CNC machining of critical surfaces to achieve tolerances within ±0.005 inches per inch.

Comprehensive Application Spectrum

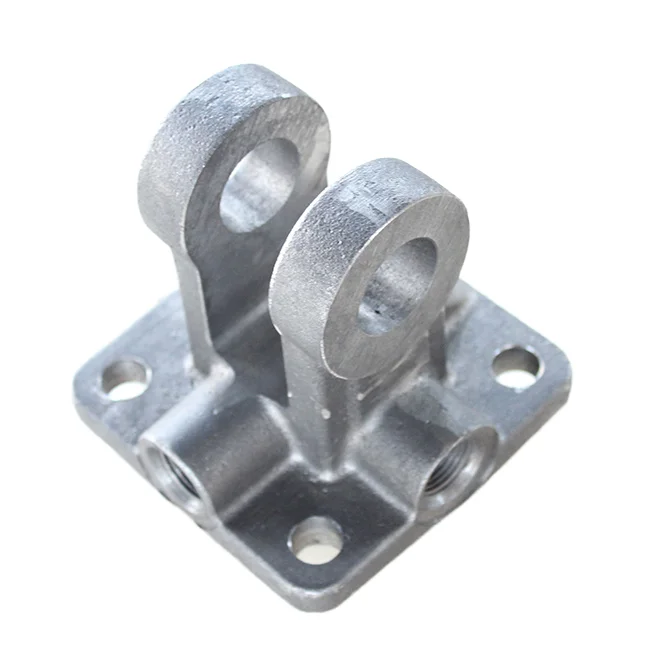

Gravity sand cast parts serve numerous demanding applications where reliability and structural integrity are paramount. In automotive sectors, we produce suspension components, engine brackets, and transmission cases. The agricultural industry utilizes our castings for implement frames, gearbox housings, and harvester components. Additionally, these parts function as hydraulic valve bodies, pump casings, and machinery bases in industrial equipment. The process's flexibility accommodates complex geometries with varying wall thicknesses, making it ideal for components requiring internal passages, mounting bosses, and reinforced sections.

Our commitment to manufacturing excellence ensures that every gravity sand casting delivers consistent quality, superior performance, and extended service life. By combining traditional foundry expertise with modern quality control systems, we provide cost-effective casting solutions that enhance product reliability while reducing total ownership costs for our clients across multiple industries.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |