- Overview

- Recommended Products

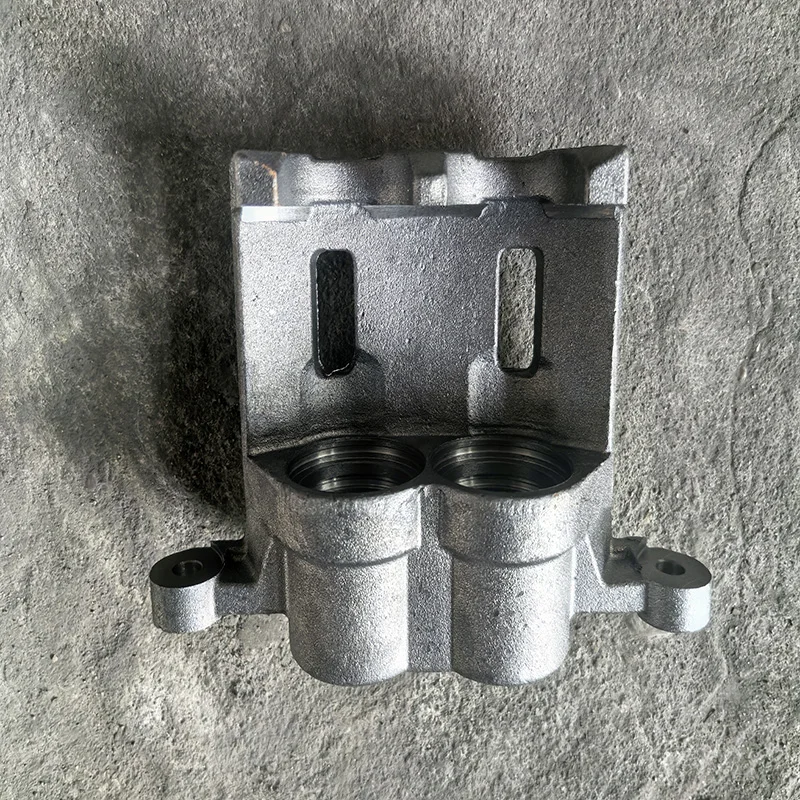

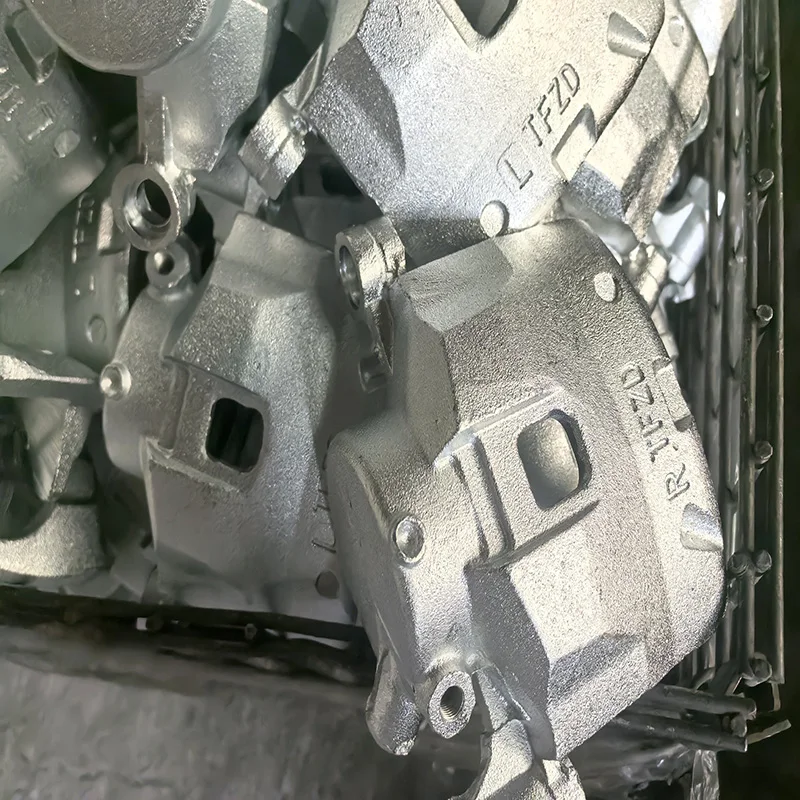

In the core of metal casting production lies a critical, often unseen component: the mold. As a specialized foundry and OEM partner, we engineer and manufacture sand cast iron molds that are specifically designed to be heat resistant for demanding metal casting operations. These durable, precision-crafted molds are the backbone of repeatable, high-quality casting production, enabling foundries to achieve superior results in creating complex metal parts.

Superior Material: Heat-Resistant Cast Iron

The performance of a casting mold is dictated by its material. Our molds are cast from specialized grades of gray and ductile iron that are formulated for enhanced heat resistance. This composition provides a critical set of properties essential for prolonged mold life and consistent performance:

Exceptional Thermal Stability: Withstands repeated, rapid heating and cooling cycles (thermal shock) without warping or cracking, maintaining dimensional integrity.

High Thermal Fatigue Resistance: The alloy's structure resists the formation of heat checks and surface cracks, even after thousands of casting cycles.

Excellent Wear Resistance: Withstands the abrasive nature of handling and sand blasting during mold preparation and cleaning.

Good Machinability: Allows for precise CNC machining of complex mold cavities, gating systems, and venting channels to exacting specifications.

Precision-Oriented Manufacturing Process

Our mold-making process is a testament to precision engineering. It begins with the creation of a high-integrity pattern. We then use advanced sand casting techniques to produce the initial iron mold (the "tooling" itself). The critical phase involves CNC machining, where the mold halves are machined to create perfectly aligned, smooth cavity surfaces. This ensures that every subsequent casting produced from this mold will have consistent wall thickness, precise geometry, and a high-quality surface finish.

Key Performance Advantages for Metal Casting

Using our OEM sand cast iron molds delivers significant operational benefits:

Extended Service Life: Superior heat resistance translates to more casting cycles before mold replacement, reducing tooling costs per part.

Consistent Casting Quality: Precision-machined cavities ensure dimensional repeatability and reduce casting defects like veining or fins.

Improved Production Efficiency: Durable, reliable molds minimize unplanned downtime for repairs or replacements.

Critical Applications in Foundries

Our heat resistant sand cast iron molds are essential tooling for foundries producing a wide range of metal parts, including:

Automotive Components: (Engine blocks, brake calipers)

Industrial Machinery Parts: (Pump housings, valve bodies)

Plumbing Fixtures and Hardware

Aerospace and Defense Castings

Elevate your foundry's capability with durable, precision-crafted tooling. Contact our foundry OEM today to discuss your custom sand cast iron mold requirements and discover how our heat-resistant solutions can enhance your metal casting productivity and quality.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |