- Overview

- Recommended Products

For modern commercial vehicles and passenger cars equipped with sophisticated drivetrains, the Dual Mass Flywheel (DMF) is critical for damping vibrations and protecting transmissions. When failure occurs, Dandong Pengxin Machinery provides the ultimate remanufacturing solution, restoring OEM performance and reliability with advanced engineering and stringent quality control. Our service represents the optimal balance between performance, durability, and cost-effectiveness for this complex component.

Premium Materials for Enhanced Durability

Our remanufacturing process begins with core disassembly and rigorous inspection. We replace all wear-prone components with premium materials: high-carbon steel for friction surfaces, advanced composite materials for the arc spring assemblies, and specialized lubricants rated for high-temperature operation. The main flywheel bodies, manufactured from high-strength nodular iron, are retained only after passing detailed magnetic particle inspection to ensure structural integrity. This material selection ensures optimal thermal stability, wear resistance, and fatigue strength – essential for handling the torsional vibrations of modern diesel and high-torque gasoline engines.

Precision Re-engineering Process

Each DMF undergoes comprehensive re-engineering in our specialized facility. The process includes:

Precision machining of contact surfaces to restore original dimensional specifications

Dynamic rebalancing to within 15 g·cm at operating speeds

Replacement of damping springs with OEM-specification or performance-grade alternatives

Application of temperature-resistant seals and specialized anti-corrosion coatings

Final assembly incorporates laser-welded housing seams and torque-to-yield fasteners, ensuring long-term reliability under extreme operating conditions.

Performance Restoration for Modern Drivetrains

Our remanufactured DMFs deliver:

95% vibration reduction efficiency matching OEM specifications

Service life exceeding 120,000 km under normal operating conditions

Compatibility with both manual and automated manual transmissions

Smooth engine start-stop system operation

These solutions are engineered for a wide range of European and Asian vehicles, including popular models from Volkswagen, BMW, Ford, and Hyundai/Kia. By restoring the original damping characteristics, our DMFs prevent damage to transmission synchronizers, reduce gear rattle, and improve overall driving comfort. The optimized mass distribution ensures prompt engine response while effectively isolating crankshaft vibrations from the drivetrain.

Dandong Pengxin Machinery's remanufactured Dual Mass Flywheels represent the smart choice for repair facilities and vehicle owners seeking reliable, cost-effective solutions without compromising on performance or longevity. Our technically advanced approach to DMF restoration ensures your vehicle maintains its designed driving characteristics and powertrain protection.

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

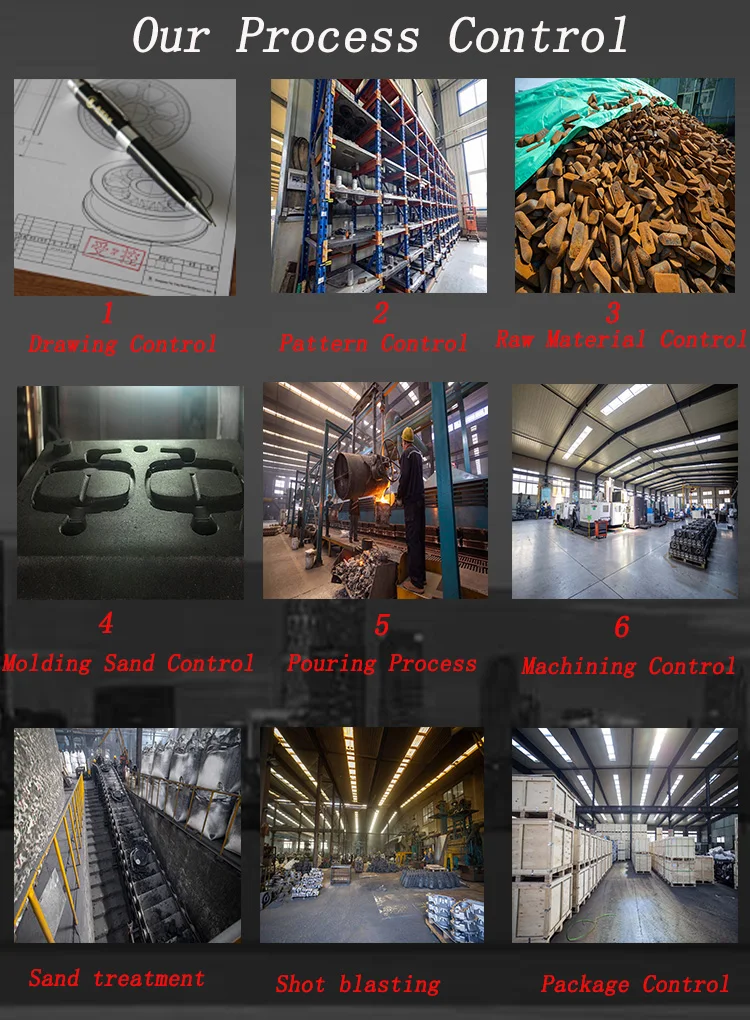

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

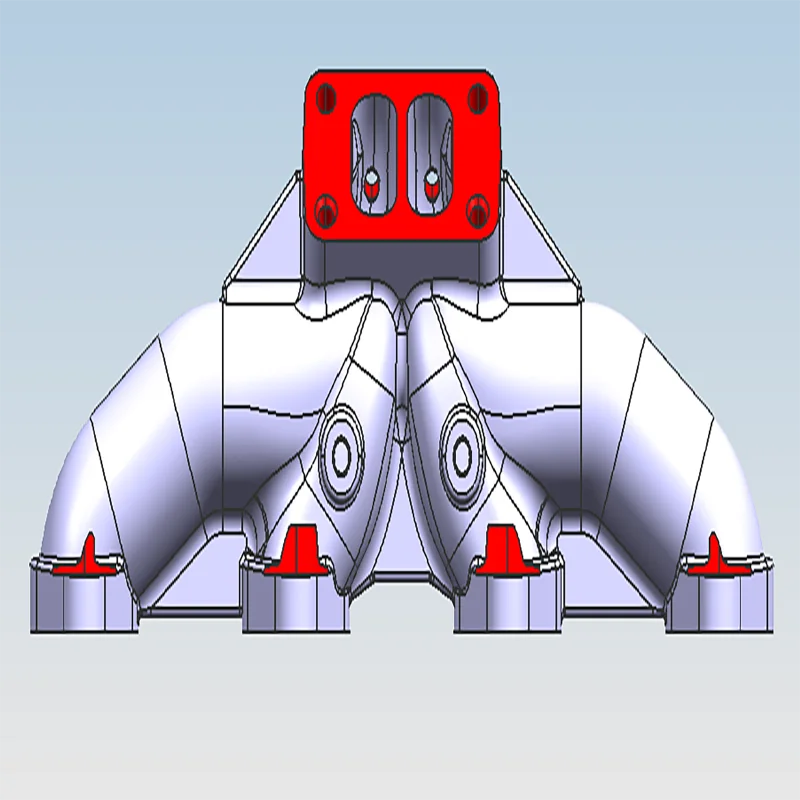

Process designs derive from engineering drawings

3D scanners

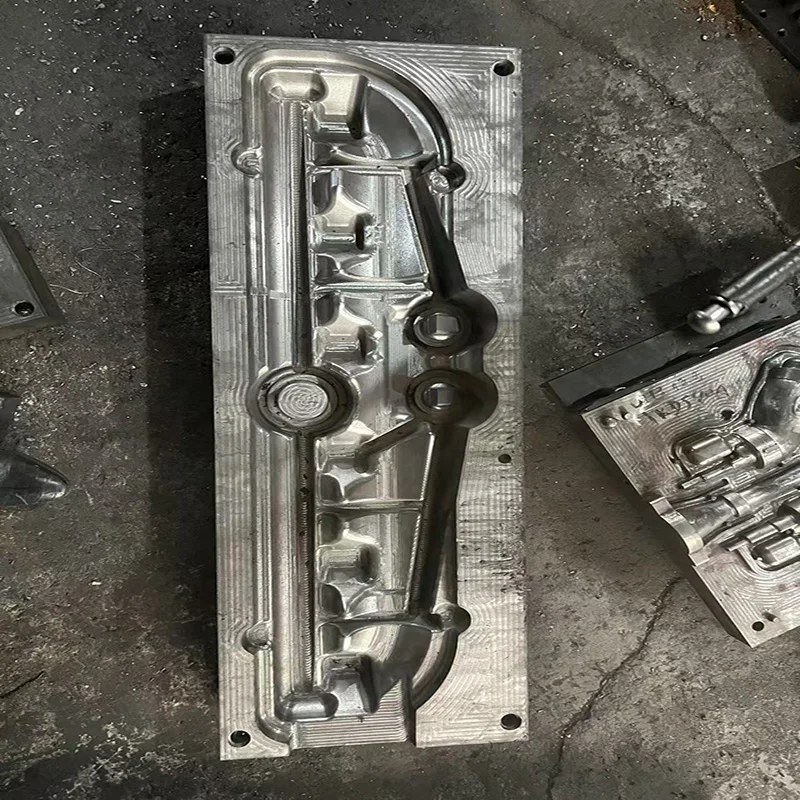

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control