Genuine VTEC and I-VTEC Diesel Engine Parts MANIFOLD EXHAUST for NT855 High Quality Casting Services

- Overview

- Recommended Products

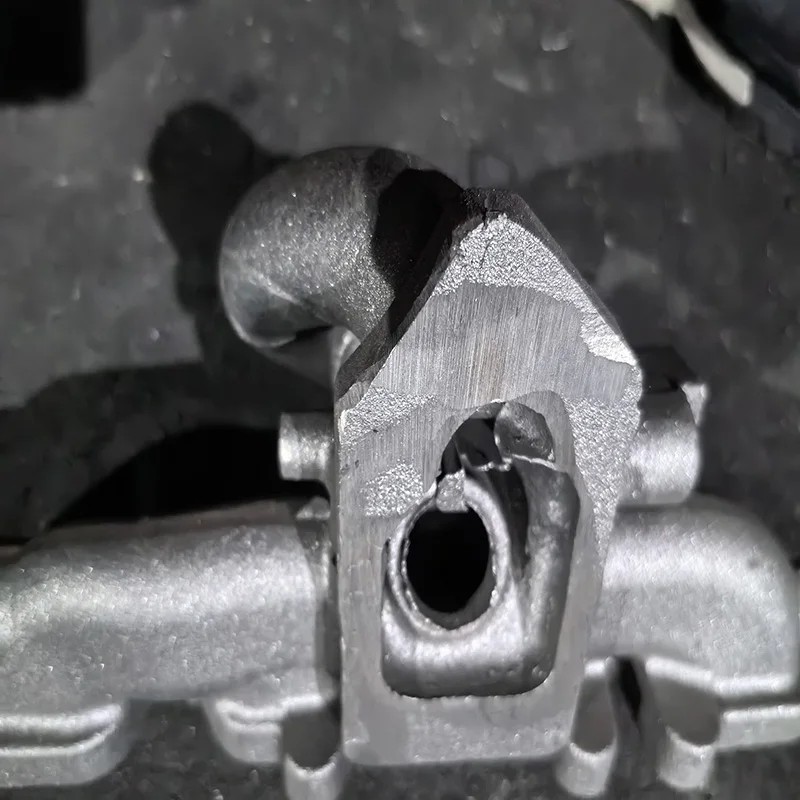

For engineers and maintenance specialists working with VTEC/I-VTEC diesel engines and Cummins NT855 platforms, the exhaust manifold represents a critical component where precision engineering meets extreme operating conditions. Our genuine replacement exhaust manifolds demonstrate how advanced casting services can optimize performance and durability in high-stress diesel applications.

Advanced Material Technology

Our exhaust manifolds utilize specialized metallurgical formulations:

High-silicon molybdenum ductile iron with vermicular graphite structure for optimal thermal conductivity

Enhanced nickel-chromium alloying (2.5-3.0% Ni, 0.8-1.2% Cr) providing exceptional oxidation resistance

Micro-alloyed composition maintaining 480 MPa tensile strength at 750°C continuous operation

Thermal fatigue resistance sustaining 1500+ cycles between 150-800°C without crack initiation

Precision Manufacturing Excellence

We employ sophisticated production methodologies:

High-pressure molded sand casting with resin-bonded cores for dimensional accuracy within ±0.15mm

Computer-controlled solidification simulation preventing shrinkage defects in critical sections

Five-axis CNC machining of all mounting surfaces achieving 0.08mm flatness tolerance

Automated robotic grinding ensuring smooth runner transitions and optimal flow characteristics

Real-time quality monitoring using optical coordinate measuring systems

Performance-Enhancing Engineering

The manifolds incorporate advanced design features:

Pulse-separated runner configuration optimizing exhaust gas scavenging efficiency

Variable wall thickness engineering (5.0-7.5mm) balancing thermal mass and weight considerations

Strategic reinforcement ribbing controlling thermal expansion stresses

Precision-machined flanges ensuring perfect seal with cylinder head and turbocharger interfaces

Integrated EGR provisions maintaining factory emissions compliance

Quality Assurance Validation

Each component undergoes rigorous testing protocols:

Hydrostatic pressure testing at 5.2 bar for 25 minutes

Thermal shock testing through 300 cycles of 100-850°C transitions

Metallographic analysis verifying graphite structure and nodularity

Vibration resonance testing simulating engine operation to 3500 RPM

Surface roughness analysis maintaining Ra ≤ 6.3 μm in gas passages

Application-Specific Compatibility

Our casting services cover multiple engine platforms:

Genuine VTEC and I-VTEC diesel engine applications

Cummins NT855 industrial and automotive variants

Both naturally aspirated and turbocharged configurations

OEM replacement and performance upgrade requirements

Technical Partnership Services

We provide comprehensive engineering support:

Finite element analysis for stress optimization and durability prediction

Rapid prototyping capabilities with 3-week delivery for development samples

Production capacity supporting both low-volume and mass manufacturing

Complete technical documentation including material certifications and test reports

For VTEC, I-VTEC, and NT855 engine applications requiring genuine-quality exhaust manifolds, our casting services deliver OEM-compliant solutions with enhanced performance characteristics. Contact our engineering team for technical specifications and manufacturing capabilities tailored to your specific requirements.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |