- Overview

- Recommended Products

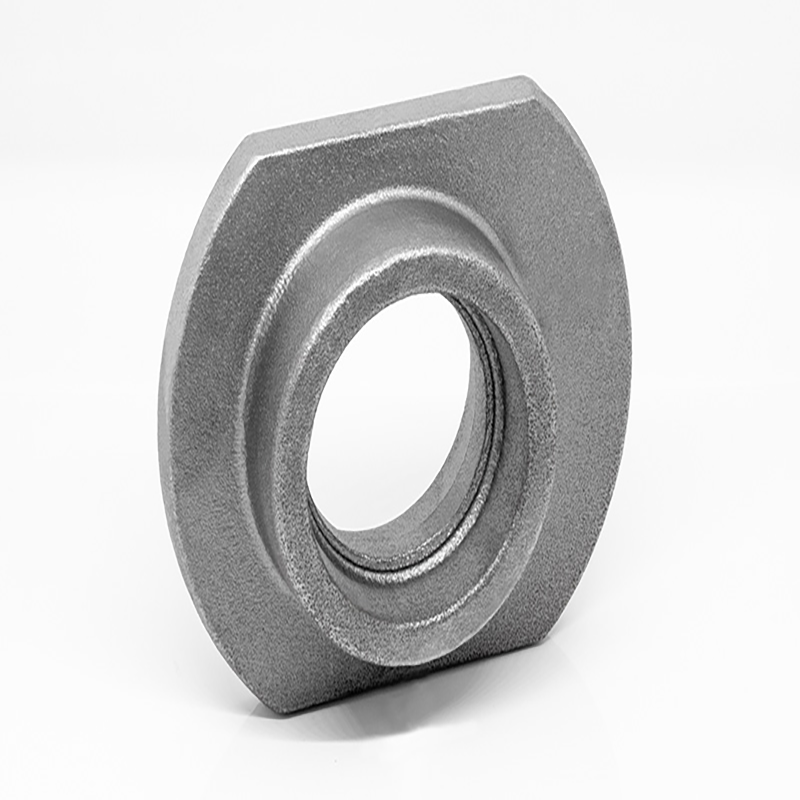

Introducing, Pengxin's Forged Parts Customized Steel Hot Forging for Auto Parts Hot Forging Service.

Pengxin's hot forging service offers customized steel forged parts for auto applications. Our advanced forging technology ensures precise and durable components that are tailor-made to meet your specific needs. Whether you need custom crankshafts, connecting rods, or any other auto part, Pengxin has you covered with high-quality, reliable solutions.

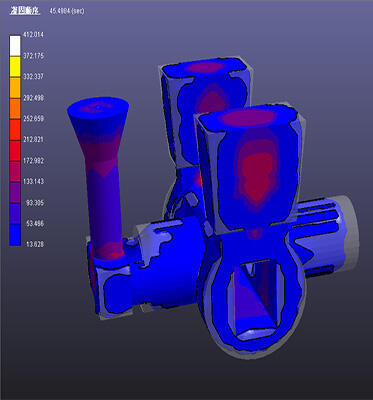

Our hot forging process involves heating the steel to a specified temperature and then shaping it with a die under extreme pressure. This results in parts that are strong, resilient, and free from defects. With Pengxin's expertise in hot forging, you can trust that your auto parts will meet the highest standards of quality and performance.

We take pride in delivering customization options to our customers. Whether you require a specific size, shape, or material, our team of experienced engineers and technicians will work closely with you to bring your vision to life. From prototype development to mass production, Pengxin ensures that every forged part meets your exact specifications and exceeds your expectations.

Pengxin's forged parts are designed to withstand the rigors of the automotive industry. With superior strength and durability, our forged components can endure heavy loads, high speeds, and harsh conditions. Whether you're building a race car, a commercial vehicle, or a personal automobile, Pengxin's hot forged parts will provide the reliability and performance you need.

In addition to quality and precision, Pengxin also prioritizes efficiency and cost-effectiveness. Our hot forging process allows for fast production speeds and minimal material waste, resulting in competitive pricing for our customers. With Pengxin, you can get premium forged parts without breaking the bank.

Choose Pengxin for all your customized steel hot forging needs. With our commitment to excellence, innovation, and customer satisfaction, we are your trusted partner for auto parts hot forging service. Contact us today to learn more about how Pengxin can help you achieve your automotive manufacturing goals

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvanized etc |

||||||

Size |

Customized |

||||||

Surface treatment |

Powder coating, electroplating, oxide, anodization |

||||||

Technics |

laser cut, bend, weld, stamp, casting, forging |

||||||

Certification |

ISO9001:2015 |

||||||

OEM |

Accept |

||||||

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

||||||

Color |

Customized |

||||||

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

||||||

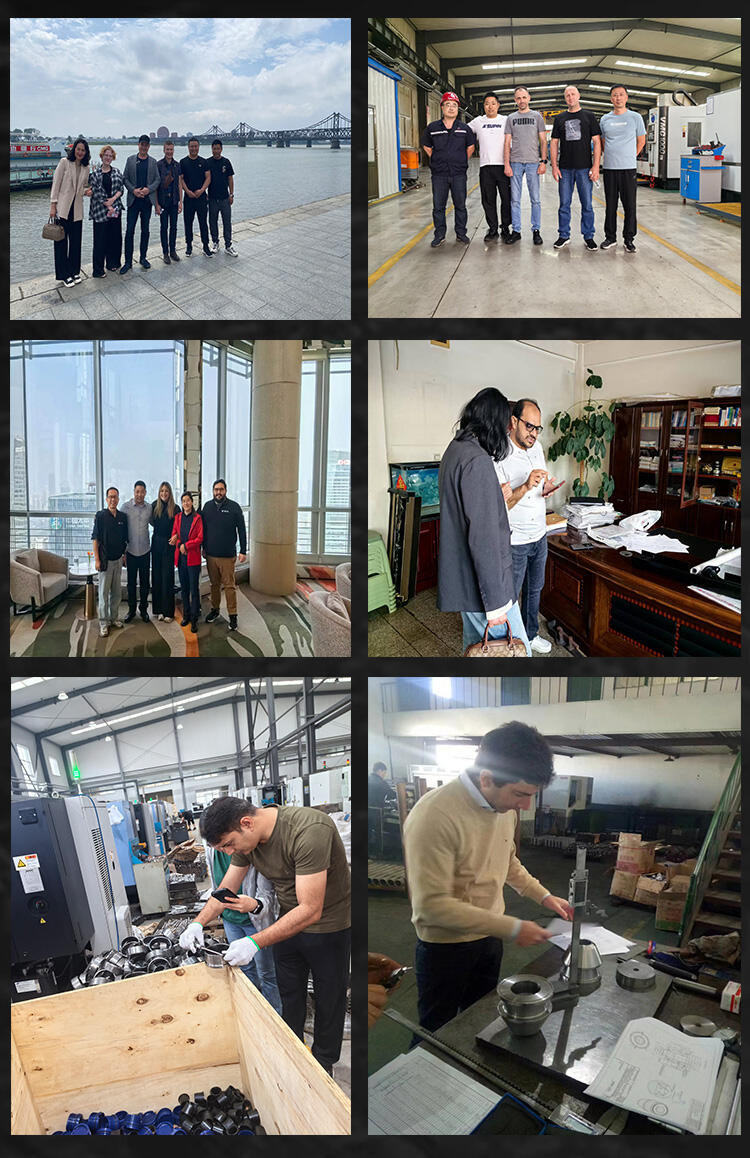

Who We Are

Pre-sales

On Sale

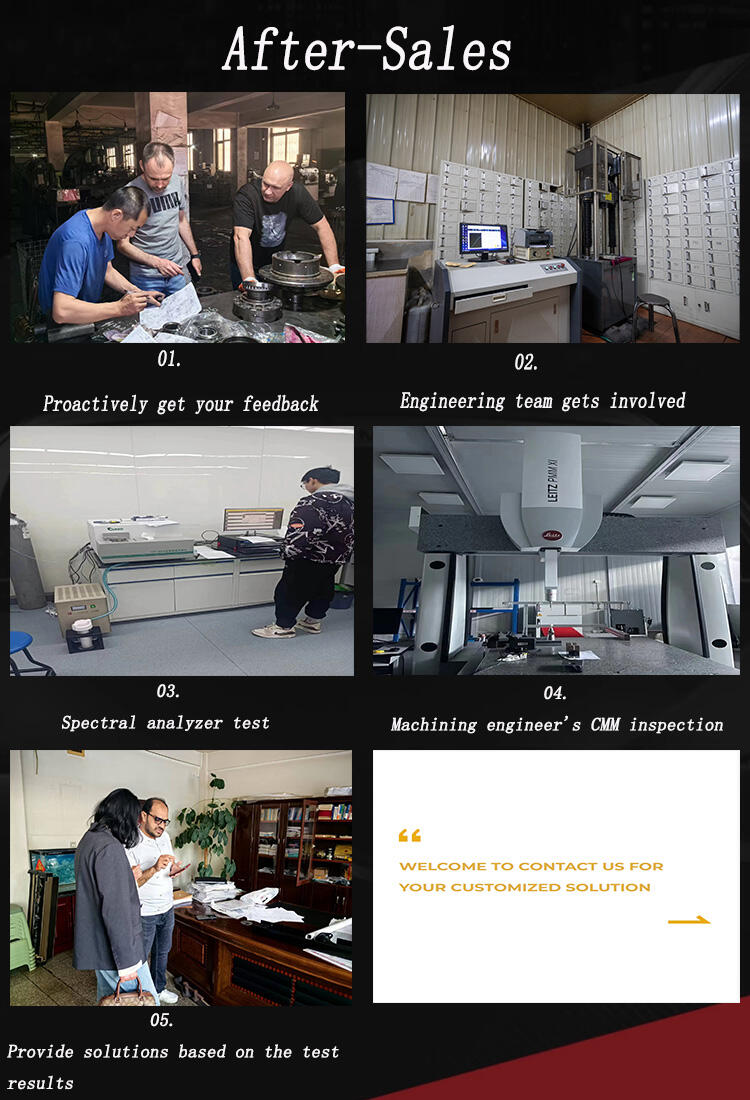

After-Sales

30,000 tons+Annual production capacity for Aluminum

80,000 tons+Annual production capacity for Steel

4000+Mold develop production

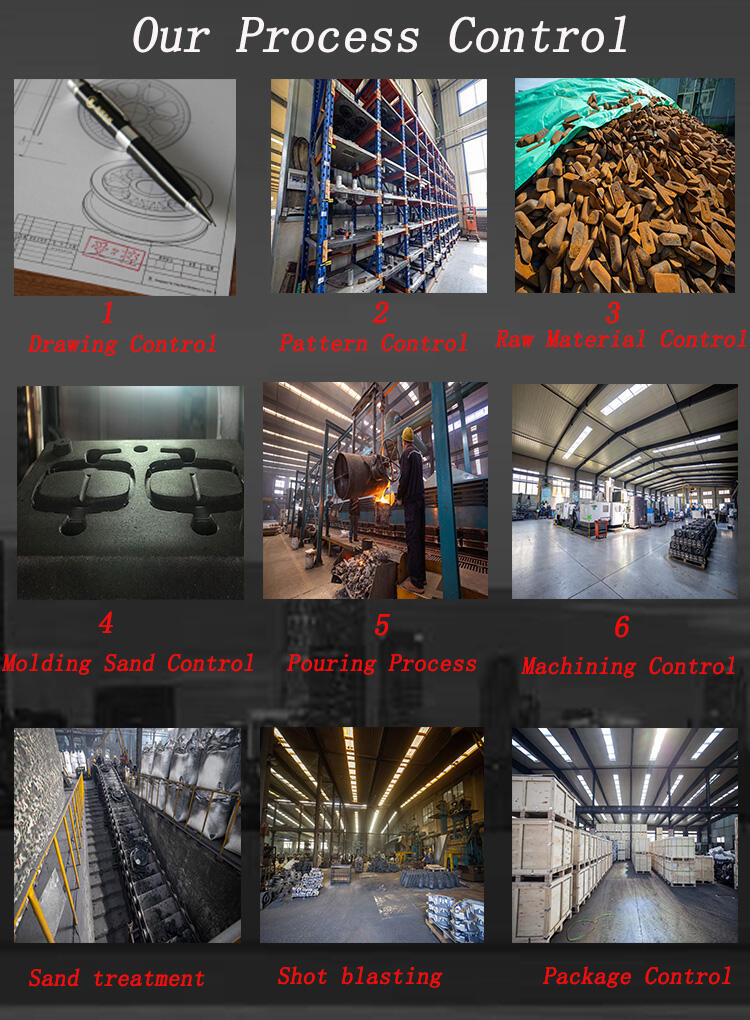

Quality Control

Pattern Control

Raw Material Control

Raw Casting & Machining Control