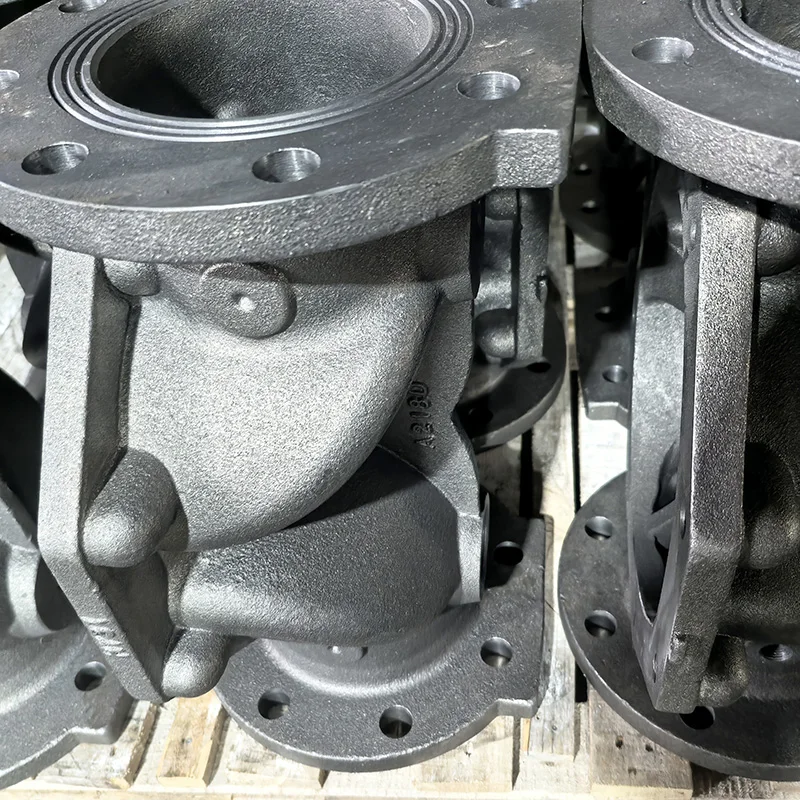

In industrial fluid systems, the pump body serves as the fundamental pressure-containing component that determines operational reliability and efficiency. Our custom sand casting service specializes in producing pump bodies using both grey iron and ductile iron materials, providing engineering solutions tailored to specific pressure ratings, media compatibility, and service conditions. This manufacturing approach combines traditional foundry expertise with modern quality control to deliver components that meet the precise requirements of OEM manufacturers across multiple industries.Material Specifications and Performance Characteristics

We offer two primary iron materials for pump body applications: grey iron (Grades G2500-G3500) for standard pressure applications and ductile iron (Grades 45010-60003) for high-pressure and high-stress conditions. Our grey iron castings provide excellent vibration damping capacity with tensile strength of 250-350 MPa, while ductile iron components deliver superior mechanical properties including 450-600 MPa tensile strength, exceptional impact resistance, and elongation up to 10%. Both materials demonstrate outstanding wear resistance against abrasive media and maintain structural integrity across temperature ranges from -20°C to 350°C, with ductile iron offering enhanced pressure tightness for demanding hydraulic applications.

Precision Sand Casting Manufacturing Process

Our foundry employs advanced sand casting technology using resin-bonded molding systems that maintain dimensional accuracy for complex pump body geometries. The process begins with custom pattern equipment designed to achieve optimal gating and feeding systems specific to each pump design. Controlled pouring parameters and real-time thermal monitoring ensure sound castings with minimal shrinkage porosity. Each pump body undergoes precision machining on CNC boring mills and machining centers, maintaining bore tolerances within ±0.001 inches and surface finishes of 3.2 μm Ra for critical sealing surfaces. The manufacturing process includes comprehensive quality verification through hydrostatic testing, dimensional inspection, and material certification.

Comprehensive Industrial Applications

Our custom-cast pump bodies serve diverse fluid handling applications across multiple sectors. Water and wastewater treatment facilities utilize our components for centrifugal pumps and slurry handling equipment. The chemical processing industry specifies our pump bodies for corrosive media transfer with appropriate lining compatibility. Industrial cooling systems, fire protection equipment, and irrigation applications all benefit from our engineered solutions. The design flexibility of sand casting accommodates various standards including ANSI, DIN, and API configurations, with capabilities for custom flange arrangements, mounting patterns, and connection specifications.

Partner with our foundry for custom sand-cast pump bodies that combine material excellence with manufacturing precision. Our technical expertise in both grey iron and ductile iron casting ensures optimal material selection for your specific application requirements, delivering components that enhance pump performance, reduce lifecycle costs, and provide reliable service across diverse operating conditions.

About Us