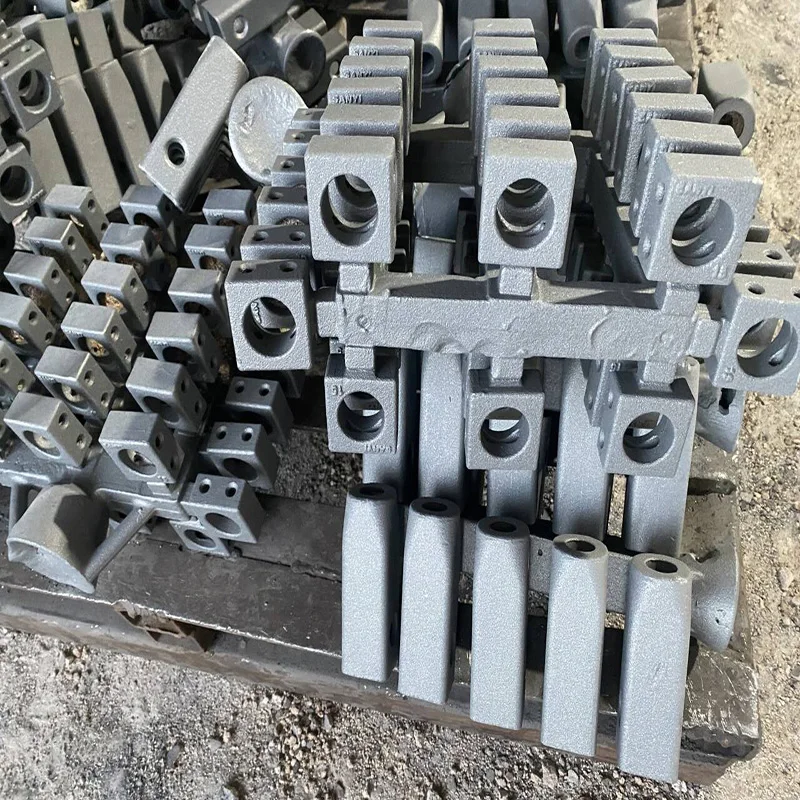

Custom Investment Casting Services for Iron Sand Casting Part for Specific Investment Casting Requirements

- Overview

- Recommended Products

As a specialized foundry in industrial components, we provide premium quality nodular iron casting services that deliver exceptional mechanical properties and reliability for demanding industrial applications. Our manufacturing expertise combines advanced metallurgical knowledge with precision casting technology to produce nodular iron components that offer superior strength, durability, and performance across various industrial sectors.

Material Excellence and Performance Characteristics

We specialize in high-grade nodular iron (also known as ductile iron) with comprehensive grade coverage including QT400-18, QT450-10, QT500-7, QT600-3, and QT700-2. These materials offer an exceptional combination of mechanical properties that make them ideal for high-stress industrial applications. The nodular graphite structure within the ferritic-pearlitic matrix provides:

Superior tensile strength ranging from 400-700 MPa

Excellent elongation properties from 2-18%

Enhanced impact resistance compared to standard cast irons

Outstanding fatigue strength for cyclic loading applications

Superior wear resistance for moving components

Good machinability with proper tool selection

Advanced Manufacturing Process

Our production methodology employs sophisticated casting techniques optimized for nodular iron:

Precision Mold Engineering

We utilize advanced sand casting systems with chemically-bonded sand molds that ensure:

Excellent dimensional accuracy and stability

Superior surface finish quality (Ra 3.2-6.3 μm)

Consistent reproduction of complex geometries

Minimal casting defects and inclusions

Controlled Metallurgical Process

Our nodular iron production features precise process control:

Computer-controlled melting in medium-frequency induction furnaces

Advanced magnesium treatment for consistent nodularization

Scientific inoculation ensuring proper graphite formation

Real-time thermal analysis for quality prediction

Protected pouring systems preventing slag inclusion

Quality Assurance and Performance Validation

Each nodular iron casting undergoes rigorous quality verification:

Spectrochemical analysis confirming material composition

Microstructure examination verifying nodularity and matrix structure

Mechanical testing validating tensile strength and elongation

Ultrasonic testing for internal integrity assessment

Coordinate measuring machine dimensional validation

Hardness testing across critical sections

Industrial Applications and Solutions

Our nodular iron castings serve demanding applications across multiple sectors:

Heavy Machinery: Gearboxes, hydraulic components, and structural frames

Automotive Industry: Crankshafts, differential carriers, and suspension components

Power Generation: Turbine components, pump housings, and valve bodies

Industrial Equipment: Press frames, machinery bases, and equipment supports

Mining and Construction: Dragline components, crusher parts, and heavy equipment elements

By combining advanced nodular iron technology with precision casting expertise, we deliver industrial components that provide reliable performance, extended service life, and cost-effective solutions for demanding applications. Our engineering team collaborates closely with clients to develop casting solutions that meet specific performance requirements, ensuring optimal design for manufacturability, superior mechanical properties, and consistent quality in every component we produce.

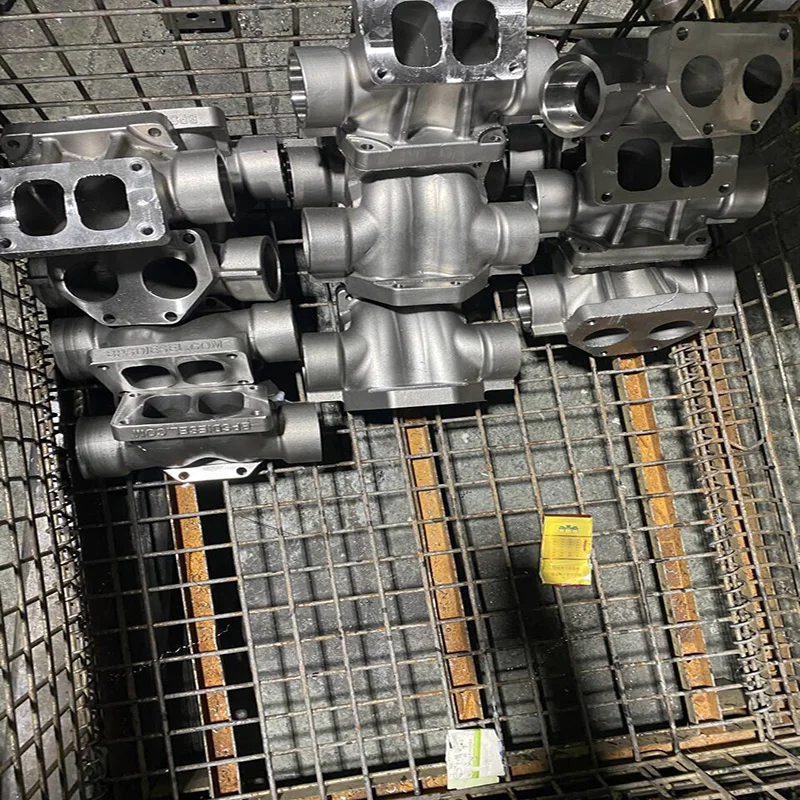

Custom Investment Casting Services for Iron Sand Casting Part for Specific Investment Casting Requirements

As a specialized foundry in precision components, we provide custom investment casting services specifically designed for iron sand casting parts that meet unique and specific investment casting requirements. Our manufacturing expertise combines the precision of investment casting technology with the versatility of iron materials to deliver components that offer exceptional dimensional accuracy, superior surface finish, and reliable performance for specialized industrial applications.

Material Excellence and Performance Characteristics

We utilize a comprehensive range of iron materials including grey iron (Grades HT200-HT350) and ductile iron (QT400-18, QT500-7, QT600-3) specifically engineered for investment casting applications. These materials offer excellent mechanical properties with grey iron providing tensile strength of 200-350 MPa and superior vibration damping capacity, while ductile iron delivers enhanced strength of 400-600 MPa with elongation ranging from 3-18%. The materials demonstrate:

Exceptional wear resistance for long-term reliability

Good corrosion resistance in various operating environments

Excellent pressure tightness for fluid handling applications

Superior machinability for precision post-casting operations

Consistent performance across temperature variations

Advanced Investment Casting Manufacturing Process

Our production methodology employs sophisticated investment casting techniques optimized for iron materials:

Precision Pattern Development

We create intricate wax patterns using aluminum injection molds designed with precise shrinkage allowances. Each pattern undergoes meticulous inspection to ensure dimensional conformity before ceramic shell building, with capabilities to produce patterns for complex geometries and tight tolerance requirements.

Ceramic Shell Engineering

Our multi-layer ceramic shell construction creates robust molds capable of withstanding high pouring temperatures specific to iron alloys. The proprietary shell formulation ensures:

Superior surface finish quality (Ra 3.2-6.3 μm)

Tight dimensional tolerances (±0.13 mm per 25 mm)

Accurate reproduction of complex internal features

Minimal inclusion defects and consistent mold strength

Controlled Casting Operations

Our specialized pouring and solidification control ensures metallurgical integrity:

Computerized melting temperature control for iron alloys

Protective atmosphere pouring preventing oxidation

Directional solidification optimization

Strategic gating and risering design for iron characteristics

Quality Assurance and Performance Validation

Each investment cast iron part undergoes rigorous quality control:

Spectrochemical analysis for precise chemical composition control

X-ray inspection for internal integrity assessment

Liquid penetrant testing for surface defect detection

Mechanical property testing to confirm performance specifications

Coordinate measuring machine dimensional validation

Microstructure examination for graphite formation verification

Customized Solutions for Specific Requirements

Our services are tailored to meet unique application needs:

Prototype Development: Rapid pattern making for design validation

Low-Volume Production: Cost-effective solutions for specialized applications

Complex Geometries: Capability to produce intricate shapes and thin walls

Specific Mechanical Properties: Custom metallurgical formulations

Special Surface Requirements: Enhanced surface finish capabilities

Industrial Applications and Solutions

Our custom investment casting services support specialized requirements across:

Automotive Industry: Complex engine components and transmission parts

Hydraulic Systems: Precision valve bodies and pump components

Food Processing Equipment: Sanitary components with smooth surfaces

Architectural Elements: Decorative ironwork with intricate details

Industrial Machinery: Specialized equipment components and wear parts

By combining advanced investment casting technology with iron metallurgical expertise, we deliver components that meet specific customer requirements while ensuring optimal performance, reliability, and cost-effectiveness. Our engineering team works closely with clients to develop customized solutions that address unique application challenges, ensuring perfect fitment, superior quality, and consistent performance for specialized iron casting applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |