Cheap Good Flexibility Bulk Lost Wax Casting Zinc/Aluminum/Copper Materials OEM/ODM Accepted From Trusted Suppliers

- Overview

- Recommended Products

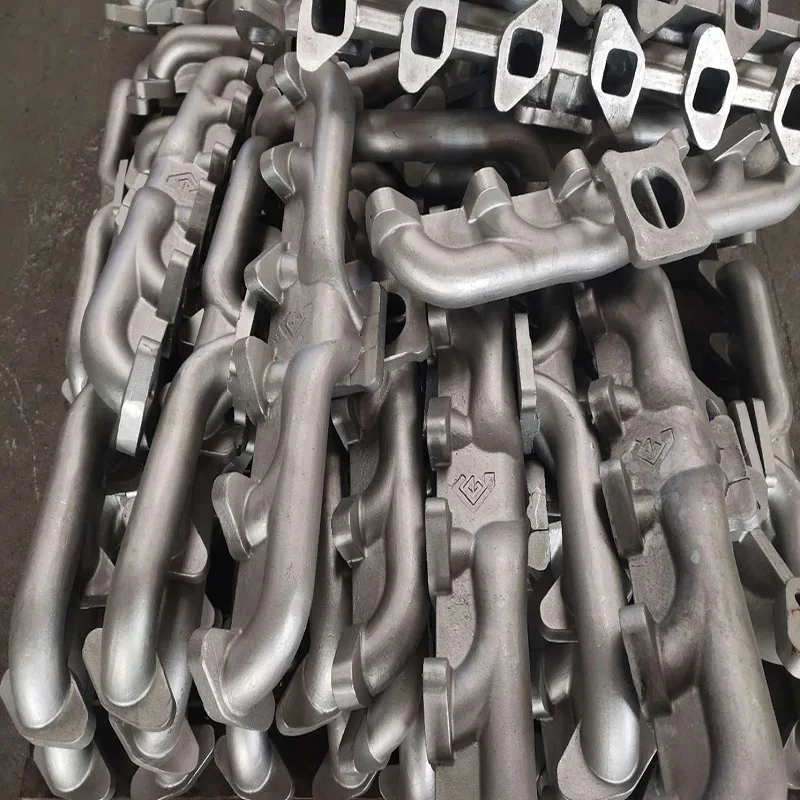

In today's competitive manufacturing landscape, lost wax casting (also known as investment casting) stands out as a versatile and cost-effective solution for producing high-precision metal components. This process is ideal for working with a range of non-ferrous metals, including zinc, aluminum, and copper alloys, making it a go-to choice for industries requiring complex geometries and excellent surface finishes. For businesses seeking reliable, high-volume production, partnering with trusted suppliers who offer OEM/ODM services ensures tailored solutions that meet specific design and functional requirements.

⭐ Key Materials and Their Advantages

The lost wax casting method supports various materials, each offering unique benefits for different applications:

Zinc Alloys: Known for their high strength and good corrosion resistance, zinc-aluminum-copper alloys (such as UNS Z35630) are recommended for general-purpose castings that require durability at a moderate cost -3. They are often used as a competitive alternative to cast iron, bronze, brass, and aluminum castings -3.

Aluminum Alloys: Prized for their lightweight nature and excellent strength-to-weight ratio, aluminum alloys also offer good corrosion resistance and machinability -5. This makes them suitable for components where reducing weight is critical without sacrificing strength.

Copper Alloys (including Brass and Bronze): These alloys provide superior electrical and thermal conductivity, excellent corrosion resistance, and inherent anti-microbial properties -8. They are widely used in electrical components, decorative pieces, and plumbing fixtures.

🛠️ The Lost Wax Casting Process

Lost wax casting is renowned for its ability to produce parts with complex shapes and fine details. The process, which can be used to create hollow metal forms -4, typically involves several key stages to ensure precision and quality:

Pattern Creation: A wax model of the part is formed, often through injection molding -5. For more complex or prototype designs, modern approaches like 3D printing are also being explored to create wax patterns -2-7.

Shell Building: The wax pattern is repeatedly dipped into a ceramic slurry and coated with refractory materials to build a robust mold -5. This is done multiple times until a sufficient shell thickness is achieved.

Dewaxing and Firing: The assembled mold is heated, causing the wax to melt and drain away, leaving a hollow ceramic shell -4-5. This shell is then fired at high temperatures to burn away any residual wax and strengthen the mold.

Pouring and Finishing: Molten metal is poured into the preheated ceramic mold -4. Once the metal solidifies and cools, the ceramic shell is broken away, revealing the metal part, which then undergoes finishing processes like cutting, grinding, and polishing.

🏭 Diverse Industrial Applications

The flexibility of lost wax casting allows it to serve a wide array of industries by facilitating the production of parts with complex shapes and hollow structures -4. Its applications include:

Automotive and Machinery: Production of engine components, turbine blades, and various mechanical parts and spares -1-5-6.

Aerospace: Manufacturing of critical parts that must withstand high stress and temperatures -5.

Art and Architecture: Creation of intricate bronze sculptures and decorative elements, leveraging the method's ability to capture fine details -4-9.

Consumer Goods: Used in the jewelry industry -10 and for producing high-quality hardware and fittings.

💎 Why Partner with Our Suppliers?

Choosing our lost wax casting services guarantees access to a proven manufacturing method capable of producing strong, precise, and complex parts from zinc, aluminum, and copper alloys. Our trusted suppliers specialize in bulk production runs, offering competitive pricing without compromising on quality. With OEM/ODM accepted, we work closely with you to customize every aspect of the process, ensuring the final product aligns with your exact specifications and application needs. This makes our service an ideal choice for cost-effective, high-quality metal component manufacturing.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |