What is Resin Sand Casting?

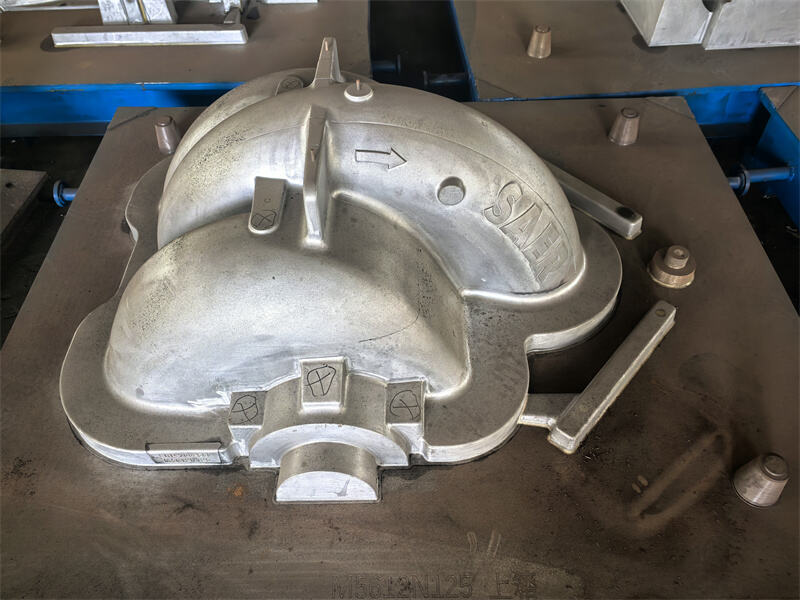

Resin sand casting is an advanced metal casting process that involves mixing high-quality raw sand with specialized resin binders (such as furan, phenolic, or alkaline phenolic resin) to form a strong, moldable sand mixture. This resin sand is then packed into mold cavities and cured—either through heat or chemical hardening—to create precise, durable molds. Once the mold is set, molten metal is poured into the cavity, producing high-integrity castings with excellent dimensional accuracy.

This method is particularly suited for complex, heavy, and large-scale industrial components where traditional green sand or shell casting may fall short in precision or structural stability.

Key Advantages of Furan Resin Sand Casting

1. Superior Surface Finish & Tight Tolerances

Delivers smooth surface roughness (Ra 12.5–25 μm)—reducing post-machining requirements.

Maintains tight dimensional tolerances (CT7–CT9 per ISO 8062), making it ideal for precision components.

2. High Efficiency & Cost-Effectiveness

Faster production cycles compared to conventional sand casting due to rapid mold curing.

Lower per-unit costs for medium to high-volume orders, optimizing batch production economics.

Excellent for heavy, large parts such as:

✓ Machine tool bodies (beds, columns, gantries)

✓ Industrial pump/valve housings

✓ Structural components (uprights, connecting beams, bases)

3. Material & Structural Benefits

Gray cast iron (HT250 / Class 30) is commonly used for machine tool castings due to its:

✓ Exceptional wear resistance for long-term durability.

✓ Superior vibration damping—critical for precision machinery.

✓ High strength-to-weight ratio for heavy-load applications.

For enhanced mechanical properties, castings undergo heat treatment processes, including:

✓ Annealing (stress relief)

✓ Normalizing (grain refinement)

✓ Quenching & Tempering (hardness/ductility balance)

Why Choose Resin Sand Casting for Large Machine Components?

Many industrial castings—such as machine tool beds, frames, and bases—require exceptional dimensional stability and structural integrity. Traditional green sand or shell casting often struggles with:

Size limitations (resin sand accommodates larger, heavier parts).

Mold stability (resin-bonded molds resist deformation during pouring).

Surface detail (finer finish with minimal defects like veining or sand erosion).

By using resin sand casting, manufacturers ensure:

✔ Higher precision for complex geometries.

✔ Better consistency in high-volume production.

✔ Reduced scrap rates due to improved mold strength.

Dandong Pengxin Machinery Advanced Manufacturing Capabilities

Our facility is equipped with:

✔ Automated resin sand production lines for consistent mold quality.

✔ State-of-the-art CNC machining centers, including:

Plano millers for large-scale surface finishing.

Horizontal milling & boring machines for precision bore machining.

Vertical machining centers (VMCs) for high-accuracy detailing.

✔ In-house heat treatment for enhanced metallurgical properties.

We specialize in high-performance industrial castings, combining material expertise, precision engineering, and efficient production to meet global standards.

Partner with Dandong Pengxin for reliable, high-quality resin sand castings—contact us today to discuss your project requirements!

Hot News

Hot News2026-02-20

2026-02-05

2026-01-21

2026-01-08

2026-01-03

2026-01-01