- Overview

- Recommended Products

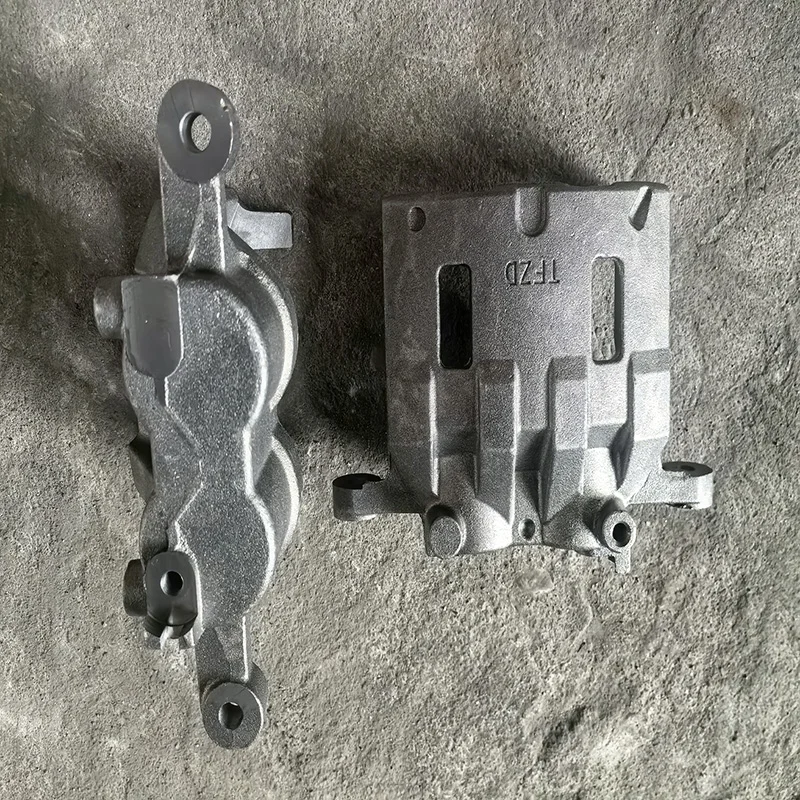

For centuries, cast iron and steel have formed the backbone of industrial and decorative manufacturing. Our integrated foundry services, specializing in Wrought Iron Steel Casting Parts, Grey Iron Casting Services, and Sand Casting Service, provide a comprehensive and versatile solution for producing durable, complex, and cost-effective metal components. This article explores the distinct characteristics of these materials and processes, highlighting their performance and applications.

Material Properties and Performance

We offer two primary ferrous materials with unique performance profiles. Grey Iron (e.g., Class 25, Class 35) is characterized by the graphite flakes in its microstructure, which give it exceptional compressive strength, superior vibration damping capacity, and outstanding wear resistance. It is also one of the easiest metals to cast, making it highly economical. In contrast, our Steel Casting Parts (including carbon and low-alloy steels) provide a different set of advantages: high tensile strength, excellent impact toughness, and good ductility. These properties make steel castings ideal for applications subject to sudden shock loads or high stress. The term "Wrought Iron" in this context refers to the finely detailed, often decorative nature of the steel castings, mimicking traditional wrought iron work but with the superior strength and reproducibility of modern steel casting.

Versatile Sand Casting Production Process

Both grey iron and steel components are predominantly produced using our Sand Casting Service. This is a highly adaptable and cost-effective molding process suitable for a wide range of part sizes, from a few kilograms to several tons. The process involves creating a mold by compacting sand around a pattern (a replica of the final part). For complex geometries, sand cores are placed inside the mold cavity to form internal passages. We utilize various sand bonding methods, including green sand (clay-bonded) for general purposes and chemically-bonded sand (e.g., resin sand) for higher dimensional accuracy and better surface finish. Once the mold is prepared, molten grey iron or steel is poured into the cavity. After solidification, the sand mold is broken away, revealing the raw casting, which is then cleaned and finished through processes like shot blasting and grinding.

Wide-Ranging Industrial and Decorative Applications

The synergy of these materials and processes serves a vast array of sectors:

Grey Iron Castings: Ideal for engine blocks, brake discs and drums, machine tool bases, hydraulic valve bodies, and heavy-duty pump housings.

Steel Casting Parts ("Wrought Iron" Style): Used for structural components in mining and construction equipment (gears, track links), high-strength architectural and decorative elements (fences, gates, staircases), and critical parts for railroad and heavy machinery.

By combining the damping and wear resistance of Grey Iron with the high strength and toughness of Steel, all through our flexible Sand Casting Service, we provide a one-stop foundry solution for both functional and aesthetic metal parts.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |