- Overview

- Recommended Products

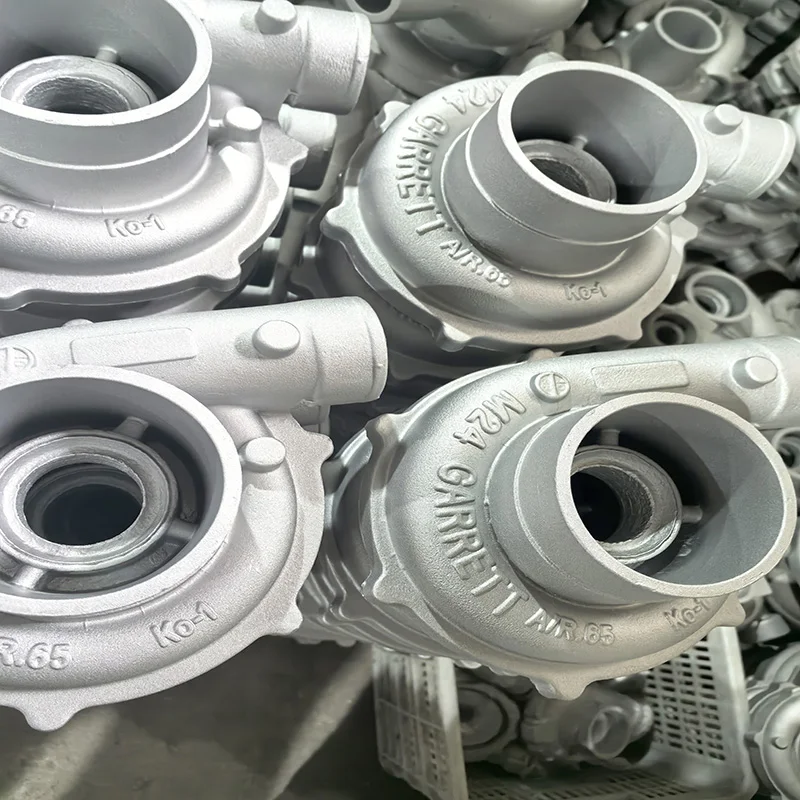

Advanced Mold Engineering for Precision Aluminum Enclosures

Our top-rated mold design factory specializes in aluminum casting enclosures through innovative vacuum investment and die casting technologies. We integrate cutting-edge mold engineering with advanced casting processes to deliver superior aluminum enclosures that meet the highest standards of dimensional accuracy, structural integrity, and surface quality for demanding industrial applications.

Premium Aluminum Alloys for Enhanced Performance

We utilize high-performance aluminum alloys specifically engineered for enclosure applications:

A356-T6: Superior strength-to-weight ratio with excellent corrosion resistance

ADC12: Outstanding fluidity and casting capability for complex geometries

A360: Enhanced pressure tightness and mechanical properties

ALSI10MG: Optimal combination of strength and thermal conductivity

All materials undergo rigorous quality verification, including spectrographic analysis and mechanical testing, ensuring consistent performance in critical applications.

Advanced Manufacturing Technologies

Precision Mold Design & Fabrication

3D CAD/CAM engineering with flow and solidification simulation

H13 steel molds with advanced surface treatments (48-52 HRC)

Conformal cooling channels for optimal thermal management

Multi-slide mechanisms and complex core systems

Rapid prototyping with 3D printed mold inserts

Vacuum Investment Casting Process

Ceramic shell molding with vacuum-assisted pouring

Precision wax patterns with ±0.15% dimensional stability

Controlled atmosphere melting and degassing

Automated shell building with consistent wall thickness

High-temperature firing (1000°C) for superior mold strength

Vacuum Die Casting Technology

800-2000 ton clamping force with vacuum systems

Porosity reduction to less than 0.1%

Real-time process monitoring and parameter control

Automated robotic extraction and quenching

In-line quality inspection systems

Enhanced Performance Characteristics

Our aluminum enclosures deliver exceptional properties:

Structural Integrity: Tensile strength 280-320 MPa, yield strength 200-240 MPa

Thin-Wall Capability: Consistent 1.5-2.0mm wall thickness maintenance

Surface Quality: Ra 1.6-3.2μm achievable without secondary machining

Pressure Tightness: Suitable for IP68 sealed enclosure requirements

Thermal Management: Excellent heat dissipation (95-125 W/m·K)

EMI Shielding: Effective electromagnetic interference protection

Quality Assurance and Certification

ISO 9001:2015 Quality Management System certified

IATF 16949 for automotive applications

UL certification for electrical enclosures

Complete material traceability and documentation

Third-party inspection and testing services

Technical Specifications

Maximum enclosure size: 600mm × 500mm × 300mm

Minimum wall thickness: 1.2mm achievable

Dimensional tolerance: ±0.0012mm per mm

Surface finish: Ra 1.6-6.3μm as-cast

Annual production capacity: 6,000 tons

Industry Applications

Electronics: Server enclosures, communication equipment housings

Automotive: ECU cases, sensor protection covers, battery enclosures

Industrial: Control panel enclosures, motor housings, instrumentation covers

Telecommunications: 5G equipment enclosures, base station components

Medical: Diagnostic equipment housings, medical device enclosures

Competitive Advantages

25+ years mold design and aluminum casting expertise

Complete in-house design and engineering support

Rapid prototyping services (3-5 working days)

Flexible production volumes from prototypes to mass production

Global technical support and logistics management

Our integrated approach combining advanced mold design with vacuum investment and die casting technologies ensures aluminum enclosures that exceed industry standards for quality, performance, and reliability. The precision engineering and rigorous quality control guarantee components that provide optimal protection and performance in the most demanding applications across multiple industries.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |