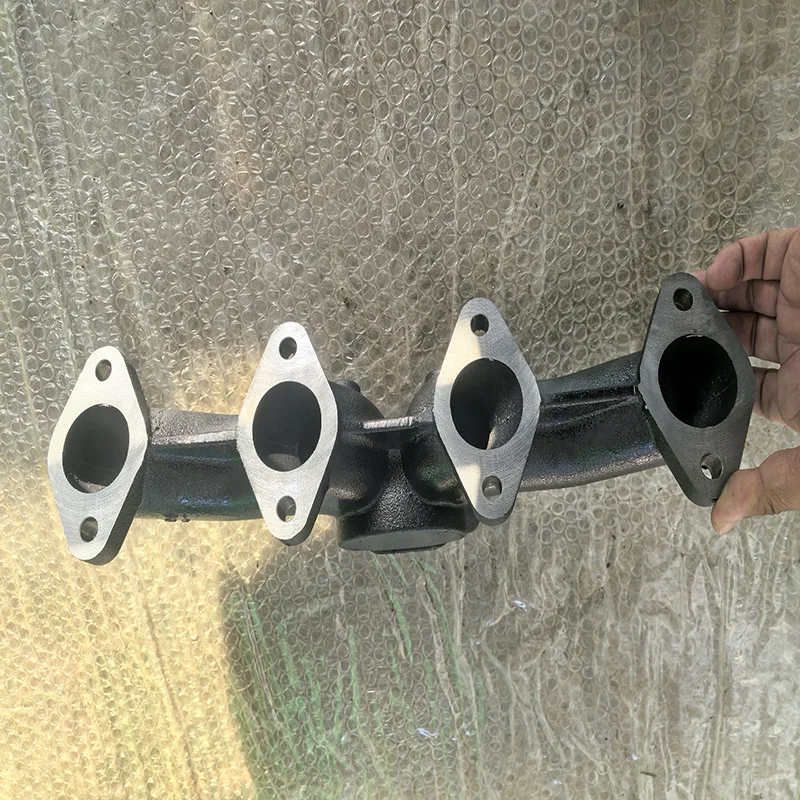

Support Four-party Turbo Exhaust Manifold Aluminum Alloy Gravity Casting High-Performance Racing Car Parts

- Overview

- Recommended Products

For professional racing teams and performance engineers developing high-output competition engines, the implementation of four-party turbo systems represents the pinnacle of exhaust technology. Our specialized aluminum alloy exhaust manifolds, manufactured through precision gravity casting processes, deliver the thermal efficiency and structural integrity required for championship-winning performance.

Advanced Material Science

Our manifolds utilize aerospace-grade aluminum alloys specifically engineered for extreme thermal management:

A356-T6 Aluminum with 7% silicon content providing optimal fluidity for complex casting geometries

Strontium-modified eutectic silicon structure enhancing mechanical properties at elevated temperatures

T6 heat treatment achieving 290 MPa tensile strength and 10% elongation at 300°C operating temperatures

Proprietary coating system combining ceramic thermal barriers with anodic oxidation for 950°C peak resistance

Precision Gravity Casting Technology

The manufacturing process employs race-proven foundry techniques:

Tilt-pour gravity casting ensuring laminar metal flow and minimal gas entrapment

CNC-machined graphite molds maintaining dimensional accuracy within ±0.3mm

Controlled solidification sequencing preventing internal shrinkage and porosity

Real-time thermal monitoring during cooling cycles optimizing metallurgical properties

Five-axis CNC finishing achieving surface flatness of 0.05mm across all mating surfaces

Four-party Turbo Integration

The manifold design incorporates critical racing-specific features:

Equal-length primary runners (tuned within 1% variation) for perfect exhaust pulse synchronization

Individual turbo flange alignment within 0.1mm ensuring optimal gasket sealing under thermal cycling

Integrated water-cooling passages maintaining consistent aluminum temperatures below 350°C

Modular collector design enabling rapid turbo configuration changes between race events

Weight-optimized structure achieving 65% mass reduction compared to traditional iron manifolds

Performance Validation

Each manifold undergoes comprehensive race simulation testing:

Thermal shock testing through 500 cycles between 100-900°C

Pressure cycling at 6.5 bar simulating sustained boost conditions

Vibration resonance analysis to 12,000 RPM engine speeds

Flow bench verification of individual runners ensuring within 2% flow variation

Strain gauge testing confirming structural integrity under extreme exhaust pressures

Professional Racing Applications

Our technology serves elite motorsport categories:

Endurance racing requiring sustained reliability under thermal stress

Time attack competition demanding immediate throttle response

Drag racing applications with rapid heat cycling requirements

Rally sports needing impact resistance and thermal durability

Technical Support Services

We provide race team-specific engineering support:

Track-side metallurgical analysis for failure prevention

Custom thermal mapping for specific circuit requirements

Rapid prototyping services with 72-hour turnaround capability

Track performance monitoring using integrated thermal sensors

For professional racing teams demanding the ultimate in turbo manifold technology, our aluminum gravity casting solutions deliver unprecedented thermal efficiency and reliability. Contact our motorsport engineering division to discuss your specific four-party turbo system requirements and discover how our advanced manufacturing processes can provide the competitive edge needed for victory.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |