- Overview

- Recommended Products

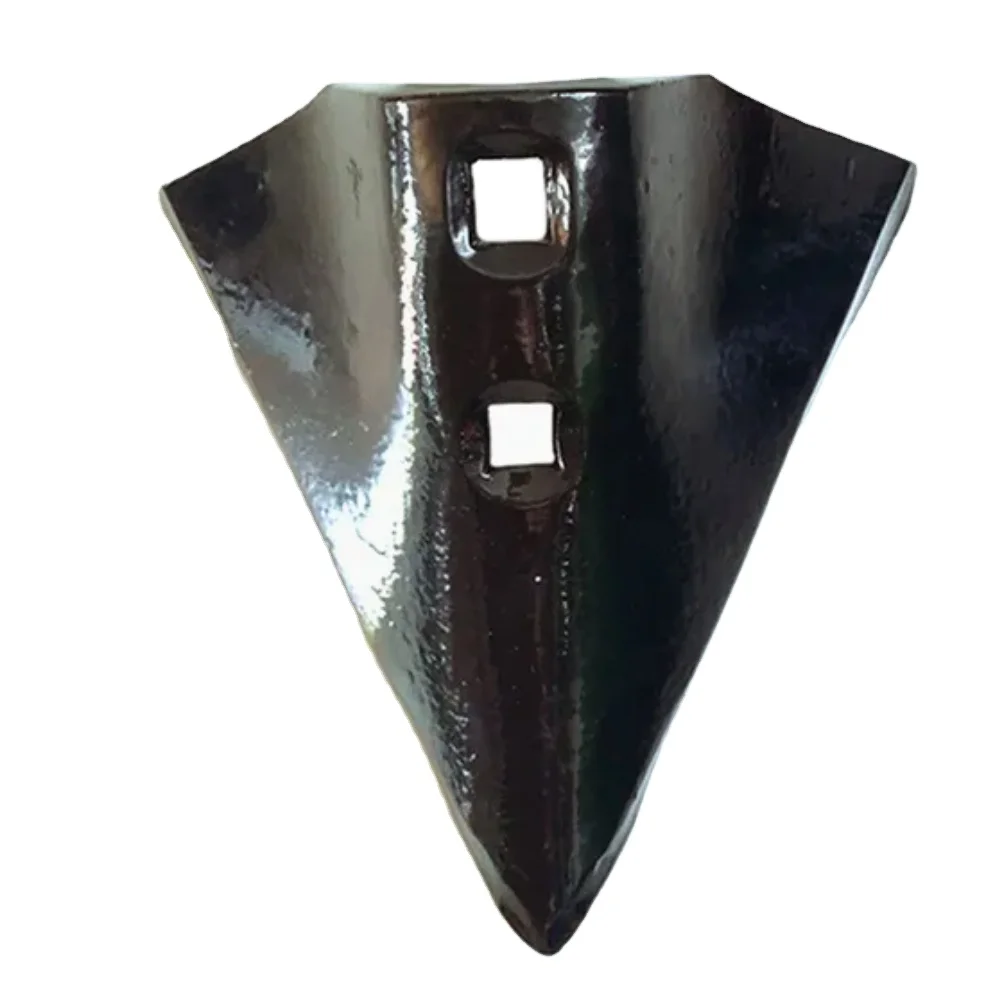

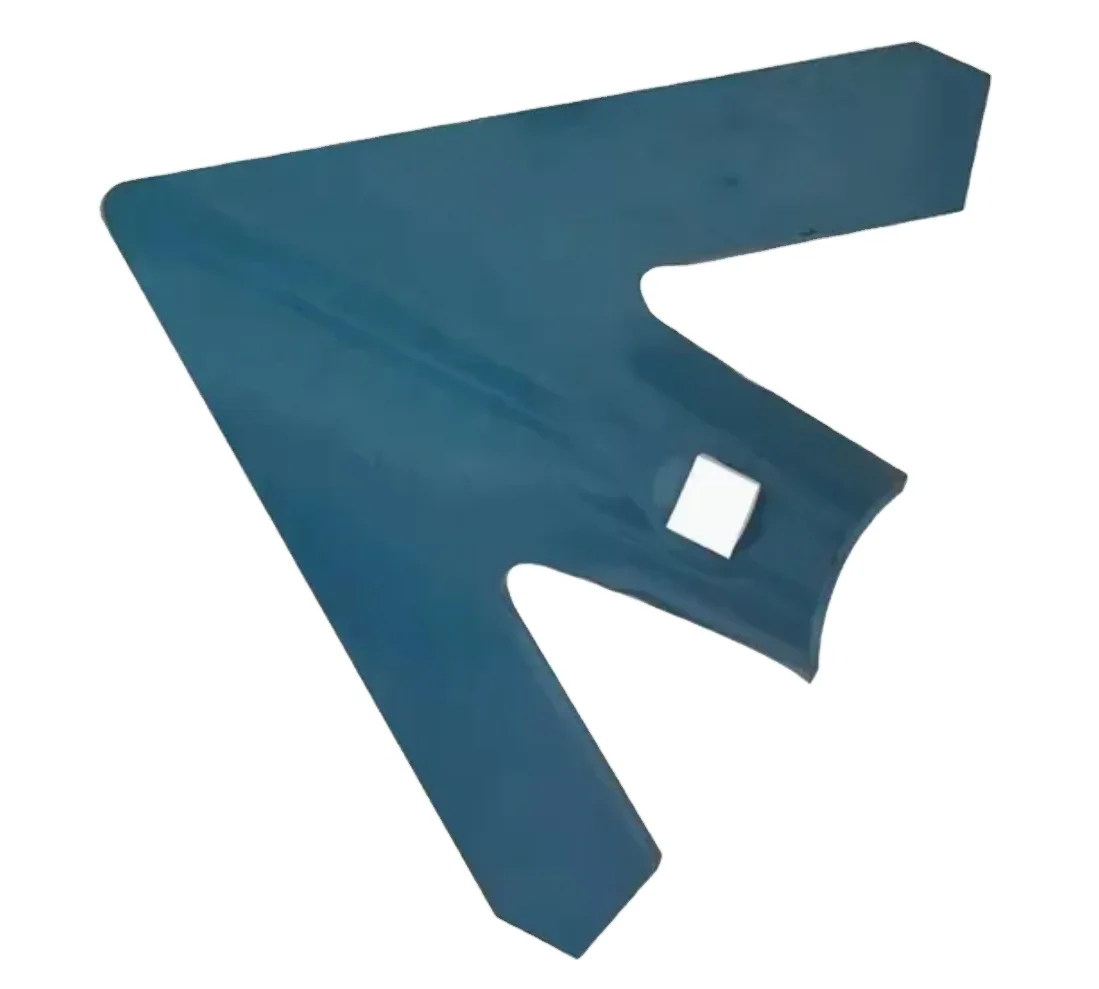

In modern agricultural cultivation, the rotary tiller break shovel serves as a critical soil-engaging component that directly determines tillage efficiency and operational costs. Our OEM casting services specialize in manufacturing high-performance break shovels for various agricultural machinery and cultivators, delivering superior wear resistance, impact toughness, and dimensional stability for demanding field conditions.

Premium Material Selection

We utilize high-carbon steel (65Mn) and boron-alloyed steel (B2) as standard materials, specifically engineered for abrasive soil conditions. These materials provide:

Surface hardness of 45-55 HRC after heat treatment

Impact toughness exceeding 25 J at room temperature

Exceptional abrasion resistance against soil minerals

Good through-hardening properties for consistent wear patterns

The 65Mn steel offers excellent elastic properties and fatigue resistance, while boron-steel variants provide up to 30% longer service life in sandy and rocky soil conditions through enhanced hardenability and wear characteristics.

Advanced Manufacturing Process

Our integrated production process combines casting and heat treatment technologies:

Pattern Making: CAD-optimized designs for optimal soil flow and reduced draft resistance

Sand Casting: Resin sand molding ensuring dimensional accuracy within CT9 level

Heat Treatment: Controlled quenching and tempering processes achieving uniform microstructure

Surface Hardening: Optional tungsten carbide overlay for extreme abrasion conditions

Post-casting processing includes:

CNC machining of mounting interfaces

Precision drilling of fastener holes

Shot peening for stress relief and surface compression

Anti-corrosion coating application

Performance Characteristics

Our break shovels demonstrate exceptional field performance:

Service life 2-3 times longer than conventional shovels

Consistent tillage depth maintenance through optimized geometry

Reduced power consumption due to efficient soil penetration

Minimal soil adhesion through polished surface treatment

Compatibility with major cultivator brands including John Deere, Kubota, and New Holland

Quality Assurance

Each shovel undergoes rigorous testing:

Hardness verification at multiple surface points

Dimensional inspection using custom gauges

Material composition analysis through spectroscopy

Field testing in various soil conditions

Our technical team works closely with agricultural equipment manufacturers to develop shovel geometries optimized for specific soil types and tillage requirements. By combining material science expertise with precision manufacturing, we deliver break shovels that significantly reduce replacement frequency and downtime while improving tillage quality and operational efficiency in modern farming operations.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |