Dandong Pengxin Machinery Co., Ltd., founded in 1958, is a private enterprise specializing in casting, machining, and assembly

ODM Customized Precision Hot Forged Services Forging Parts with Aluminum Alloy Stainless Steel Metal

- Overview

- Recommended Products

Pengxin is proud to offer top-of-the-line ODM Customized Precision Hot Forged Services Forging Parts made from premium quality aluminum alloy and stainless steel metal. Our expertly crafted forged parts are designed to meet the highest standards of precision and durability, making them the ideal choice for a wide range of applications.

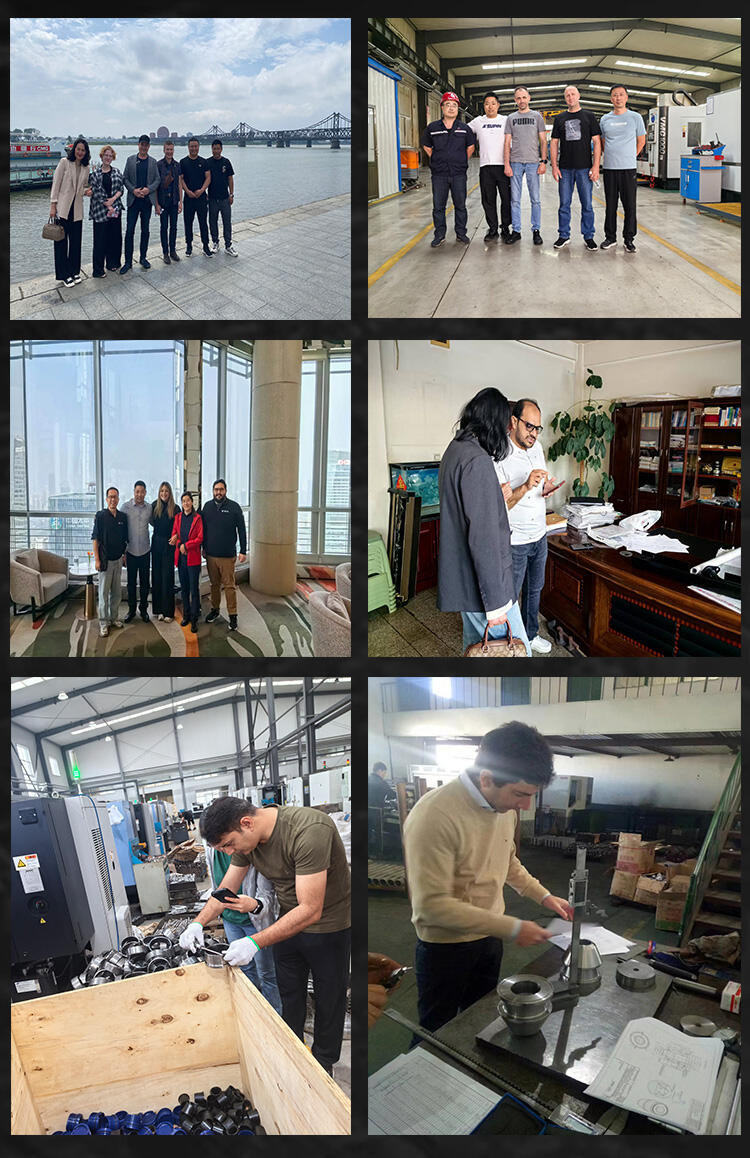

Whether you need custom-forged parts for automotive, aerospace, construction, or any other industry, Pengxin has you covered. Our experienced team of engineers and technicians work closely with each client to ensure that every part is tailor-made to their exact specifications. We utilize advanced forging techniques to create parts that are not only precise and reliable but also incredibly strong and resistant to wear and tear.

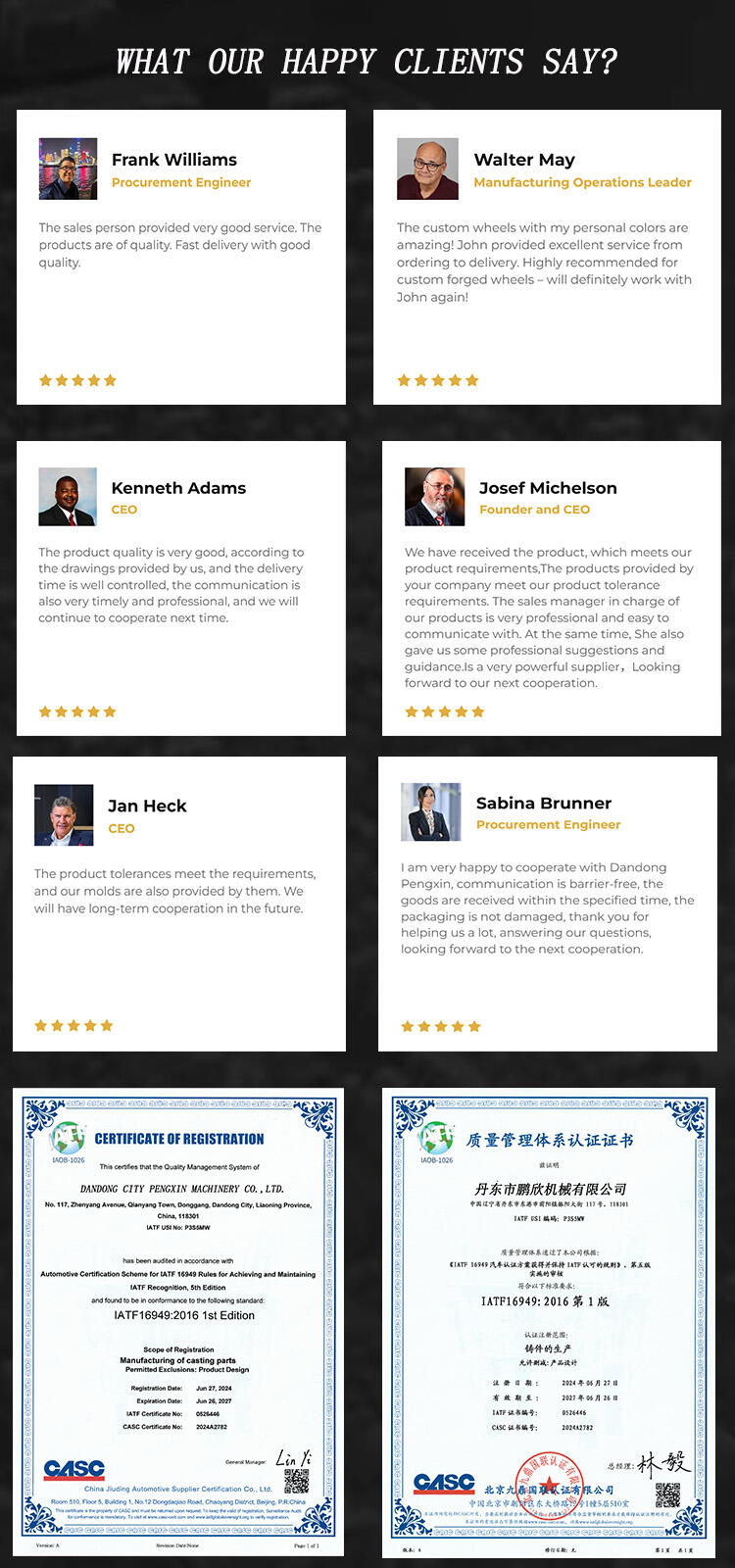

One of the key benefits of choosing Pengxin for your forging needs is our commitment to quality. Our forged parts undergo rigorous testing and inspection processes to ensure that they meet our strict quality control standards. This means that you can trust that every part you receive from Pengxin will perform flawlessly and stand up to the demands of your application.

In addition to our dedication to quality, Pengxin also offers unmatched customization options. We understand that every project is unique, which is why we work closely with our clients to create forged parts that are tailored to their specific needs. From design and material selection to finishing and packaging, we can customize every aspect of your forged parts to ensure that they perfectly meet your requirements.

Whether you need a small batch of custom-forged parts or a large-scale production run, Pengxin has the capabilities to handle any project with efficiency and precision. Our state-of-the-art facility is equipped with the latest forging equipment and technology, allowing us to deliver fast turnaround times without compromising on quality.

Choose Pengxin for all your ODM Customized Precision Hot Forged Services Forging Parts needs and experience the difference that top-quality materials and expert craftsmanship can make. Contact us today to learn more about our forging services and how we can help bring your project to life with our custom-forged parts

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvanized etc |

||||||

Size |

Customized |

||||||

Surface treatment |

Powder coating, electroplating, oxide, anodization |

||||||

Technics |

laser cut, bend, weld, stamp, casting, forging |

||||||

Certification |

ISO9001:2015 |

||||||

OEM |

Accept |

||||||

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

||||||

Color |

Customized |

||||||

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

||||||

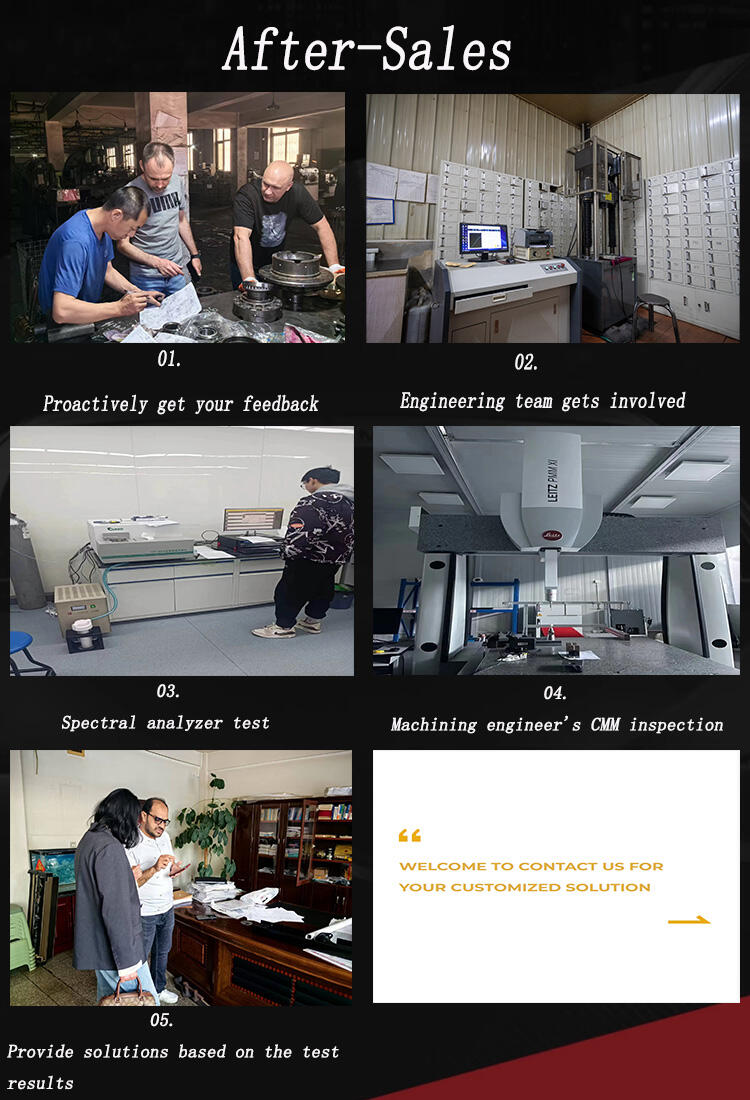

Pre-sales

On Sale

After-Sales

30,000 tons+Annual production capacity for Aluminum

80,000 tons+Annual production capacity for Steel

4000+Mold develop production

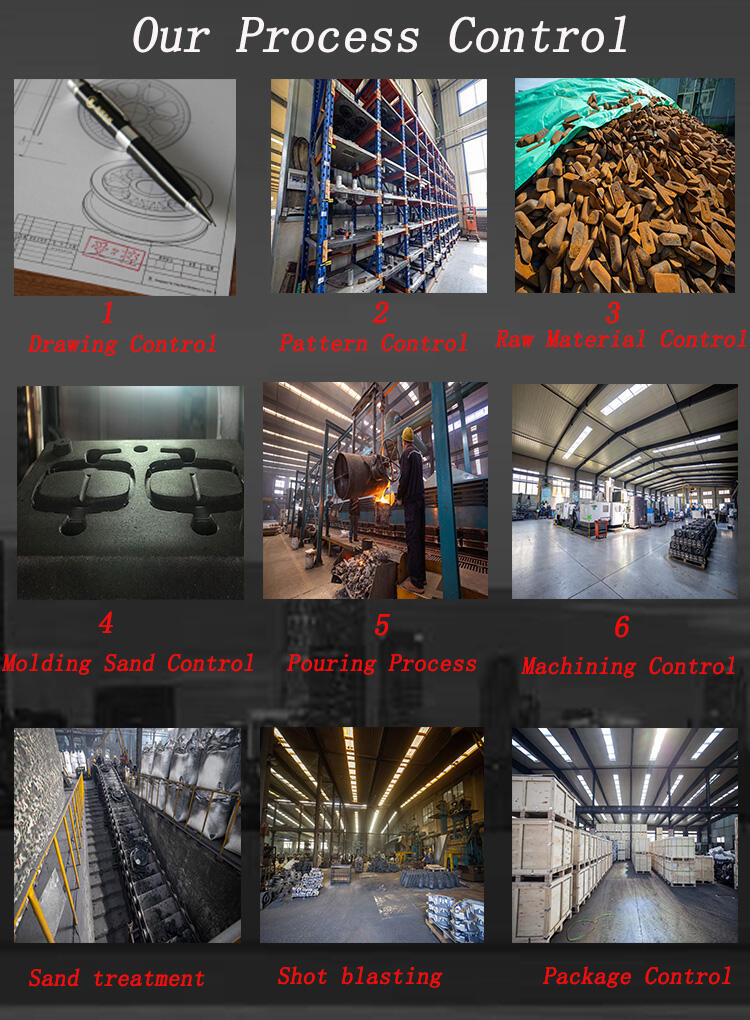

Quality Control

Pattern Control

Raw Material Control

Raw Casting & Machining Control