- Overview

- Recommended Products

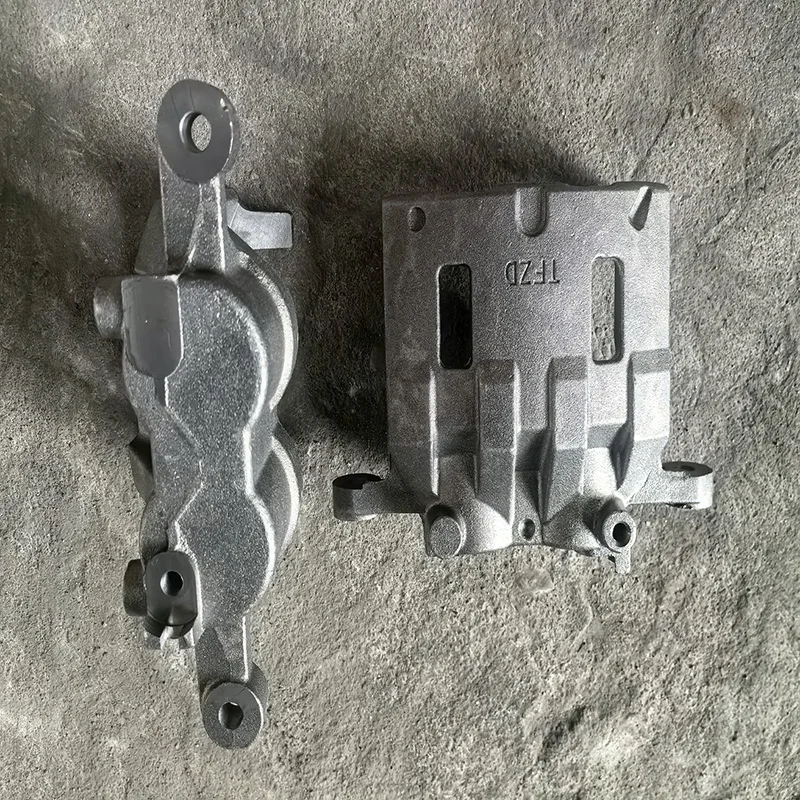

Dandong Pengxin Machinery stands as a leading manufacturer specializing in high-performance custom-made cast iron parts. We leverage decades of expertise to produce precision components primarily using two superior engineering materials: Ductile Iron (Nodular Cast Iron) and Gray Cast Iron. Our commitment to advanced production processes, rigorous quality control, and customer-specific solutions makes us a trusted partner for industries worldwide. This page provides an in-depth look at our manufacturing capabilities, material science, and the factors influencing our competitive ductile iron products price.

1. Material Excellence: Ductile Iron vs. Gray Cast Iron

The choice of material is fundamental to the performance of a cast part. We excel in selecting and processing the right alloy for your application.

-

Ductile Iron (Nodular Cast Iron):

Properties: Characterized by the presence of spheroidal graphite nodules, achieved through a magnesium or cerium treatment. This structure gives ductile iron exceptional strength, toughness, and ductility. It offers a high yield strength and excellent impact resistance, making it superior to gray iron in many demanding applications.

Advantages: Combines the casting simplicity of cast iron with the mechanical properties similar to steel. It also exhibits good wear resistance and damping capacity.

Typical Applications: Automotive components (crankshafts, differential carriers), hydraulic valve bodies, heavy-duty gears, pump housings, and agricultural machinery parts.

-

Gray Cast Iron:

Properties: Defined by its flake graphite microstructure. This graphite structure provides excellent damping capacity (vibration absorption), good thermal conductivity, and outstanding machinability.

Advantages: It is cost-effective for a wide range of applications and is easily cast into complex shapes. Its self-lubricating properties due to graphite make it suitable for wear surfaces.

Typical Applications: Engine blocks and cylinder heads, brake discs and drums, machine tool bases, electrical boxes, and general machinery housings.

2. The Pengxin Production Process: A Synergy of Art and Science

Our manufacturing is a meticulously controlled sequence, ensuring consistency, precision, and high quality in every part.

Step 1: Pattern & Mold Making

We create precise patterns (from wood, metal, or plastic) based on your CAD drawings or samples. For complex geometries, we utilize 3D Printing (Rapid Prototyping) to create accurate patterns and cores, significantly reducing lead times for prototypes and short runs.

Step 2: Molding and Core Making

We employ advanced molding techniques:

Green Sand Molding: A highly efficient and versatile method for medium to high-volume production.

Resin Sand Molding: Used for larger castings or when superior surface finish and dimensional accuracy are required. This process produces robust molds that can withstand the high metallostatic pressure of molten iron.

Step 3: Melting and Pouring

The charge materials (pig iron, steel scrap, and alloys) are melted in state-of-the-art medium-frequency induction furnaces. This ensures precise temperature control and superior metallurgical quality. For ductile iron, the nodularization treatment is performed in-line to ensure the formation of perfect graphite spheroids.

Step 4: Cooling and Shakeout

The poured molds are left to cool in a controlled environment. Once solidified, the castings are separated from the molding sand in the shakeout process.

Step 5: Finishing and Secondary Operations

Fettling: Removal of gates, runners, and excess material.

Shot Blasting: Cleaning the casting to achieve a uniform, clean surface finish.

Heat Treatment: Applied as needed (e.g., annealing, normalizing, quenching, and tempering) to enhance mechanical properties like hardness, strength, and stress relief.

Machining: We offer comprehensive precision machining services. Our workshop is equipped with CNC lathes, milling machines, and drilling machines to deliver finished parts ready for assembly, adhering to tight tolerances specified by our clients.

Step 6: Quality Assurance and Inspection

Quality is integral to our process. We implement:

Spectrochemical Analysis: To verify the chemical composition of the molten metal.

Dimensional Inspection: Using CMMs, calipers, and gauges.

Mechanical Property Testing: Tensile, hardness, and impact tests.

Non-Destructive Testing (NDT): Including magnetic particle inspection or liquid penetrant testing to detect surface defects.

3. Factors Influencing Custom Ductile Iron Products Price

The price of custom ductile iron parts is not a single figure but is determined by several project-specific factors:

Part Complexity & Design: Intricate shapes with thin walls, deep pockets, or complex cores require more sophisticated patterns and molding, increasing the cost.

Order Quantity: Higher volumes typically benefit from economies of scale, reducing the unit price.

Dimensional Tolerances & Surface Finish Requirements: Tighter specifications demand more precise tooling, careful processing, and additional inspection, impacting the price.

Required Secondary Operations: The need for heat treatment, precision machining, painting, or special packaging adds to the overall cost.

Material Specification: The specific grade of ductile iron (e.g., QT500-7, QT700-2) and any special alloying requirements affect the raw material cost.

Why Choose Dandong Pengxin Machinery?

Expertise in Cast Irons: Deep specialization in both Ductile and Gray Iron.

End-to-End Service: From design consultation and prototyping to full-scale production and final machining.

Quality Commitment: Certified quality management system ensuring reliable and consistent output.

Competitive Pricing: Optimized processes and efficient management allow us to offer excellent value.

Global Export Experience: We are a Google-verified manufacturer, and our professional online presence ensures we are easily discoverable by international clients seeking reliable casting partners.

Contact Us Today for a Competitive Quotation.

For your project requiring custom ductile iron or gray iron castings, partner with Dandong Pengxin Machinery. Provide us with your drawings or specifications, and we will deliver a detailed analysis and a transparent, competitive price.

Product Name |

casting parts/Die Casting Parts/sand casting part/aluminum die casting parts |

Casting Service |

Die Casting, Sand Casting, Gravity Casting, etc. |

Material |

QT200, 250,HT250, Aluminum ADC12, etc (Aupon your requirements.) |

Tooling Design |

We have own R&D team to make customized tooling, usually 7-15days can be ready. |

Standard |

China GB high precision standard. |

Surface Finish |

Mill Finishing, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. |

Drawing |

3D Drawing: .step / .stp, 2D Drawing: .dxf/ .dwg / .pdf |