- Overview

- Recommended Products

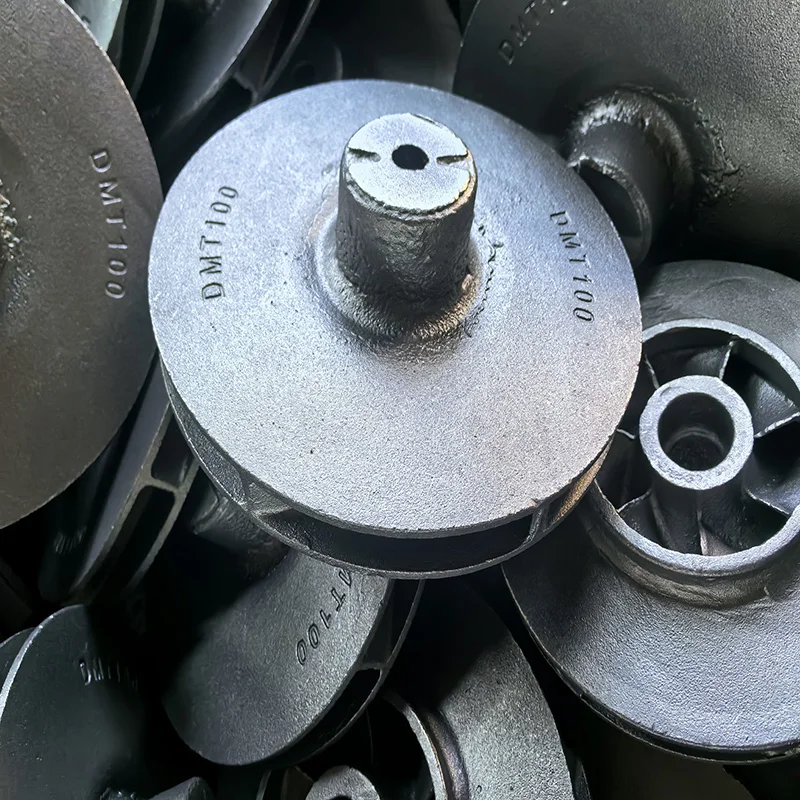

Our specialized iron and resin sand casting services deliver precision-engineered chemical pump bodies designed for demanding industrial applications. Utilizing advanced resin sand molding techniques combined with high-quality iron alloys, we produce pump bodies that offer exceptional corrosion resistance, mechanical strength, and long-term reliability in aggressive chemical environments.

Material Excellence

We employ premium iron alloys specifically formulated for chemical applications:

Gray Iron (GG25/GG30): Excellent vibration damping characteristics with tensile strength of 250-300 MPa

Ductile Iron (GGG40/GGG50): Enhanced impact resistance and pressure tightness through spherical graphite structure

Ni-Resist Iron: Superior corrosion resistance for acidic and alkaline environments

Special Alloy Irons: Chromium and nickel-alloyed variants for extreme chemical exposure

Advanced Manufacturing Process

Our resin sand casting methodology ensures superior dimensional accuracy and surface quality:

Pattern Engineering: Precision tooling design with CAD/CAM systems

Sand Preparation: Furane resin sand mixing with controlled catalyst ratios

Mold Formation: Automated molding with proper venting and gating systems

Metal Pouring: Controlled temperature pouring at 1380-1420°C

Solidification Management: Optimized cooling rate control

Finishing Operations: Shot blasting, machining, and quality inspection

Performance Characteristics

Pressure rating: Up to 25 bar operating pressure

Temperature resistance: -20°C to 350°C continuous operation

Corrosion resistance: Excellent performance in pH 4-11 range

Surface finish: Ra 12.5-25 μm as-cast, improvable to Ra 3.2 μm

Dimensional accuracy: CT10-CT12 tolerance grades

Quality Assurance

Comprehensive quality control measures include:

Spectrochemical material analysis

Ultrasonic and radiographic testing

Dimensional verification with CMM

Pressure testing and leak detection

Mechanical property validation

Microstructure examination

Industrial Applications

Chemical Processing: Acid and alkali transfer pumps, reactor circulation pumps

Pharmaceutical Industry: SANITARY process pumps, CIP systems

Water Treatment: Chemical dosing pumps, neutralization systems

Oil and Gas: Chemical injection pumps, pipeline additive systems

Pulp and Paper: Bleaching chemical pumps, stock preparation systems

Technical Advantages

Complex geometry capability with precise internal passages

Reduced machining requirements through near-net-shape production

Excellent surface quality for enhanced fluid dynamics

Superior metallurgical properties with controlled microstructure

Cost-effective manufacturing for medium to high volumes

Customization Capabilities

Size range from 100mm to 1500mm pump body diameters

Multiple flange standards (ANSI, DIN, JIS)

Custom impeller chamber designs

Integrated mounting configurations

Special coating and lining options

Our iron and resin sand cast chemical pump bodies combine advanced manufacturing techniques with rigorous quality control to deliver components that ensure reliable performance in the most challenging chemical processing applications. With extensive experience in chemical industry requirements, we provide solutions that meet both technical specifications and operational demands for durability and maintenance efficiency.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |