- Overview

- Recommended Products

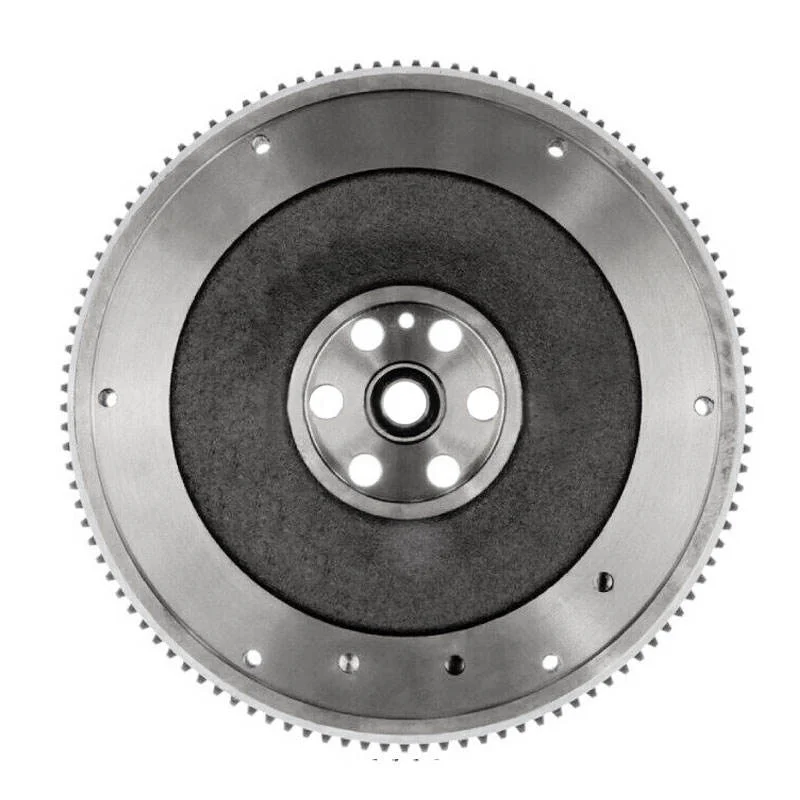

For BMW enthusiasts and professional builders seeking optimal engine response and performance, our RHD lightweight performance flywheel delivers exceptional results for M50, M52, M54, S50, S52, and S54 engine applications. Engineered with a heavy-duty 240mm clutch surface, this precision component significantly reduces rotational mass while maintaining durability for both street and track use. The perfect upgrade for drivers wanting quicker throttle response, improved acceleration, and enhanced shifting performance in their BMW vehicles.

Material Excellence & Construction

Aircraft-Grade 4140 Chromoly Steel: Tensile strength of 950 MPa with superior fatigue resistance

Precision CNC-Balanced Design: Weight reduction of 35-40% compared to OEM dual-mass units

Surface-Enhanced Friction Face: Induction hardened to 45-50 HRC for extended clutch life

Heat-Treated Ring Gear: Laser-cut teeth with case hardening for reliable starting performance

Advanced Manufacturing Process

-

CNC Machining Precision

Billet machining from solid chromoly stock

0.005" runout tolerance for vibration-free operation

Stress-relieving thermal cycles between machining operations

-

Performance Engineering

Computer-optimized inertia calculations

Finite element analysis for stress distribution

Dynamic balancing to within 10 g-cm at 10,000 RPM

-

Quality Validation

Magnetic particle inspection for material integrity

Surface hardness verification across multiple points

Dimensional validation using CMM technology

Performance Advantages

Instant Throttle Response: Reduced rotational mass improves engine acceleration

Enhanced Shift Speed: Allows quicker rev matching and smoother gear changes

Improved Durability: Single-piece design eliminates dual-mass failure points

Heat Management: Superior thermal stability during aggressive driving

Direct Engagement Feel: Provides immediate power transfer and feedback

Technical Specifications

Clutch Surface: 240mm heavy-duty design

Weight: 7.2kg (approximately 40% reduction from OEM)

Balance: Zero-balanced for universal application

Compatibility: Works with standard and performance clutch discs

Applications

BMW 3 Series (E36, E46)

BMW 5 Series (E39)

BMW Z3 and Z4 Models

Track and Performance Applications

Upgrade your BMW's performance with our engineered lightweight flywheel. Experience the transformation in throttle response and shifting precision. Contact us for compatibility details and technical specifications.

About Us

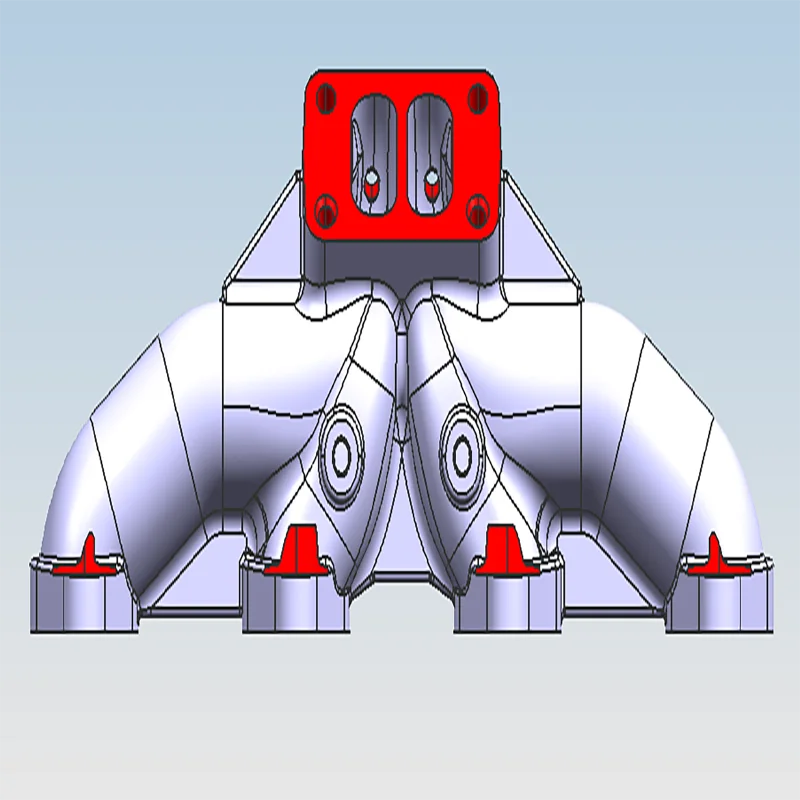

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

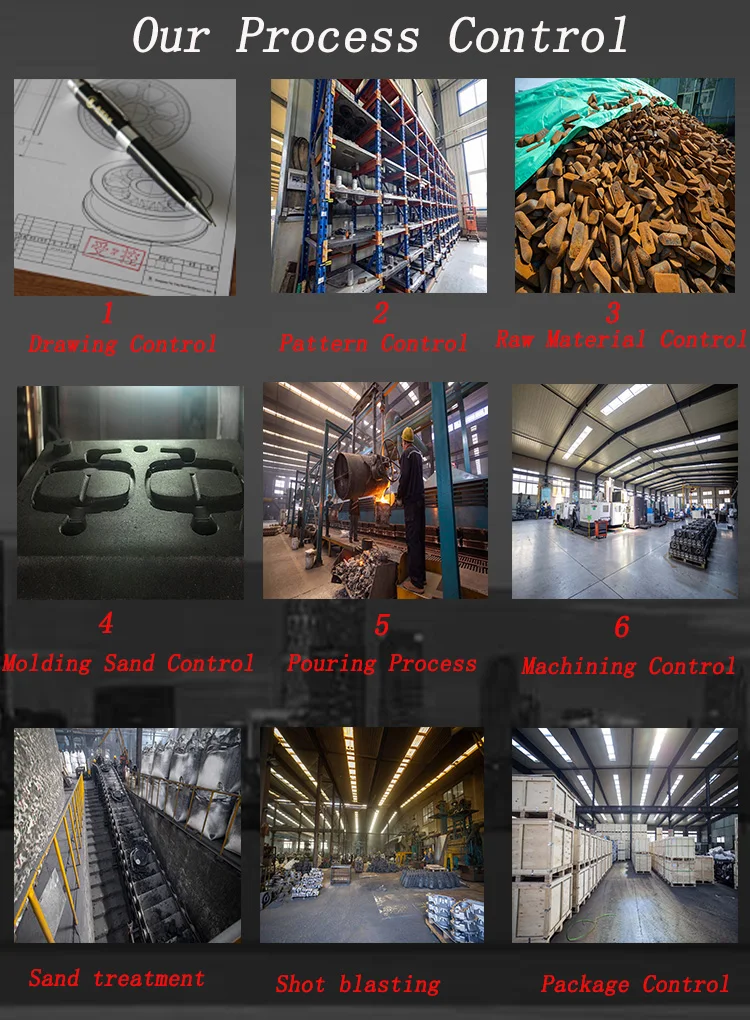

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

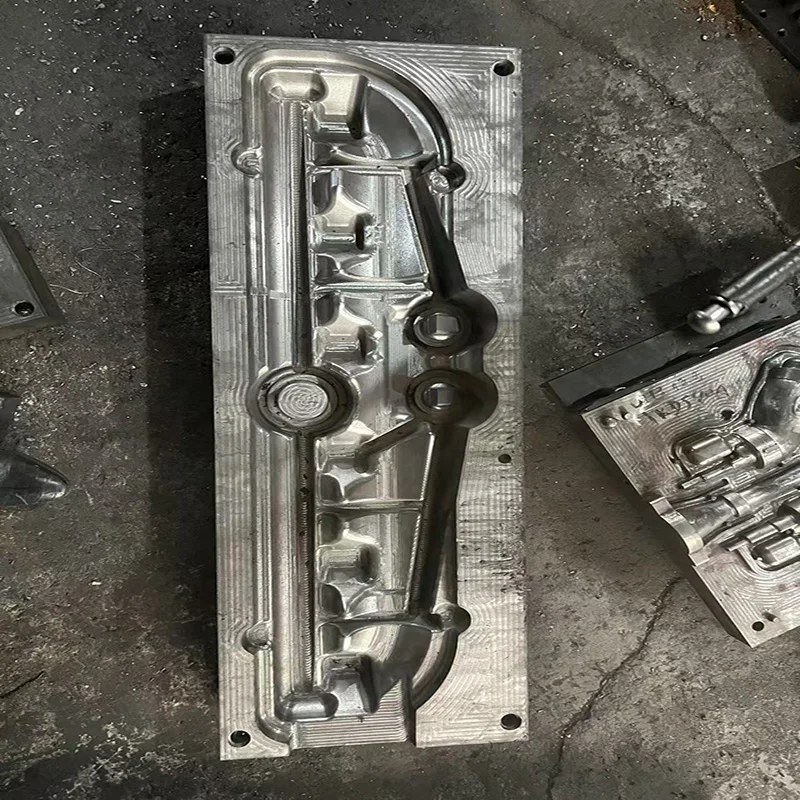

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control