- Overview

- Recommended Products

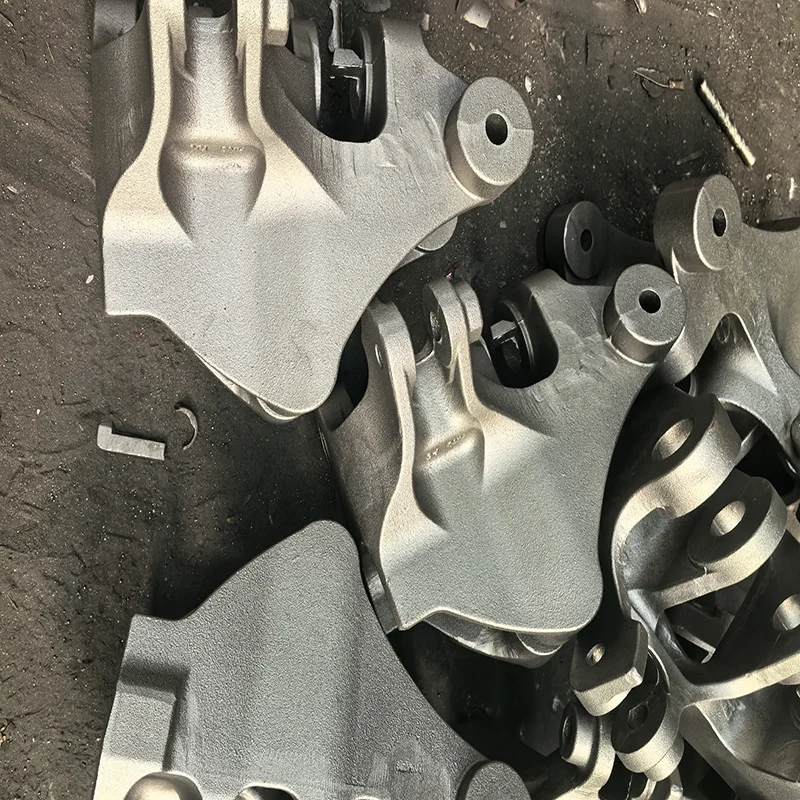

Precision Investment Casting for Superior Iron Components

Our metal casting factory specializes in investment casting services for both grey iron and ductile iron components, delivering precision parts with exceptional surface quality and dimensional accuracy. Utilizing the lost-wax process, we manufacture complex iron castings that meet the most demanding requirements across various industrial sectors, providing reliable solutions where performance and precision are paramount.

Advanced Material Selection and Properties

We offer comprehensive iron casting capabilities with focus on material excellence:

Grey Iron Grades:

Class 25 (G2500): Tensile strength 250 MPa, excellent vibration damping

Class 30 (G3000): Tensile strength 300 MPa, good wear resistance

Class 35 (G3500): Tensile strength 350 MPa, superior machinability

Class 40 (G4000): Tensile strength 400 MPa, enhanced strength properties

Ductile Iron Grades:

400-18 (GGG40): Good impact resistance and elongation

500-7 (GGG50): Balanced strength and ductility

600-3 (GGG60): High strength with good wear resistance

700-2 (GGG70): Premium grade for high-stress applications

All materials feature controlled microstructure and undergo rigorous metallurgical testing to ensure consistent performance.

Enhanced Performance Characteristics

Our investment cast iron components deliver outstanding operational benefits:

Superior surface finish (Ra 3.2-6.3 μm) reducing machining requirements

Excellent dimensional accuracy with tolerances to ±0.005 inches per inch

Good pressure tightness for fluid handling applications

Enhanced mechanical properties through precise microstructure control

Superior wear resistance in abrasive environments

Excellent machinability for secondary processing operations

Precision Investment Casting Process

Our sophisticated manufacturing ensures quality:

Pattern Development

Wax injection molding with precision temperature control

3D printed patterns for rapid prototyping

Assembly of complex pattern clusters

Quality verification of pattern dimensions

Shell Building

Multi-layer ceramic shell application

Controlled drying environment maintenance

High-temperature firing (1000°C) for optimal shell strength

Shell quality inspection and testing

Casting & Finishing

Controlled atmosphere melting and pouring

Precision temperature management (±15°C)

Automated shell removal and cutting

Heat treatment for enhanced properties

Quality Assurance Protocol

Comprehensive dimensional inspection using CMM

Ultrasonic testing for internal integrity

Mechanical property verification

Microstructure examination

Surface quality assessment

Technical Specifications

Part size range: 0.1 kg to 50 kg

Wall thickness: 3 mm to 75 mm

Dimensional tolerance: CT4-CT6 per ISO 8062

Surface finish: Ra 3.2-12.5 μm as-cast

Annual capacity: 1,200 tons of iron castings

Industry Applications

Automotive components and transmission parts

Hydraulic valve bodies and pump components

Machinery parts and equipment components

Hardware and tooling applications

Architectural and construction elements

Competitive Advantages

30+ years iron casting expertise

Complete in-house pattern making

Engineering support for design optimization

Flexible production volumes

Global quality certifications

Our investment casting services for grey and ductile iron combine traditional foundry expertise with modern precision manufacturing, delivering components that excel in performance, durability, and reliability. The superior surface finish and dimensional accuracy achieved through our investment casting process significantly reduce machining costs while ensuring consistent quality across production batches.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |