- Overview

- Recommended Products

For operators of HINO and ISUZU trucks, reliability and durability are not just preferences—they are business necessities. The flywheel, a critical link between the engine and transmission, plays a fundamental role in powertrain integrity. Our specialized flywheels are engineered to meet the rigorous demands of these renowned Japanese commercial vehicles, ensuring smooth power transfer, reliable starts, and extended service life under the heaviest loads.

Robust Material for Longevity and Performance

We manufacture flywheels for HINO and ISUZU trucks using high-strength cast iron or forged steel. These materials are selected for their exceptional wear resistance, high thermal capacity, and superior vibration-damping properties. This robust construction is essential to withstand the constant engagement and disengagement of heavy-duty starter motors and the high-torque input from diesel engines. The material's integrity prevents warping, surface hot-spotting, and cracking, which are common failure points in demanding commercial applications.

Precision Engineering for Perfect Operation

Our production process combines advanced casting or forging with precision CNC machining. This ensures perfect flatness of the friction surface, critical for preventing clutch chatter and ensuring smooth engagement. The gear ring, either heat-treated and welded or machined integrally, is manufactured to exact specifications for flawless starter motor engagement, even in cold weather. Each flywheel is dynamically balanced to a high standard to eliminate vibrations that can damage transmission input shaft bearings and other driveline components, promoting overall powertrain health.

Direct Fitment for Unmatched Reliability

Designed as direct replacements for OEM parts, our flywheels guarantee a perfect fit for a wide range of HINO and ISUZU truck models, including popular series like the HINO 300/500/700 and ISUZU NPR/NRR/F-Series. A high-quality flywheel is essential during clutch replacement to ensure the entire assembly functions as intended. Using our product restores like-new performance, providing dependable service for hundreds of thousands of miles in distribution, construction, and long-haul applications.

Trust in our specialized flywheels to deliver the durability and precision that HINO and ISUZU trucks are built for, minimizing downtime and maximizing your fleet's operational efficiency.

About Us

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

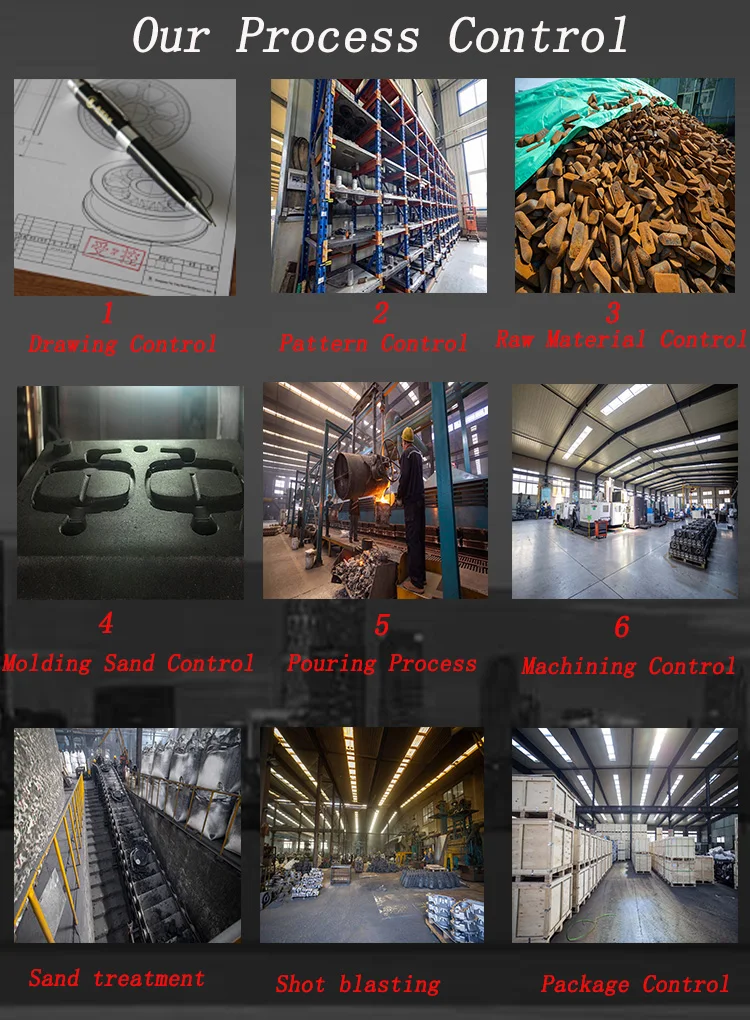

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

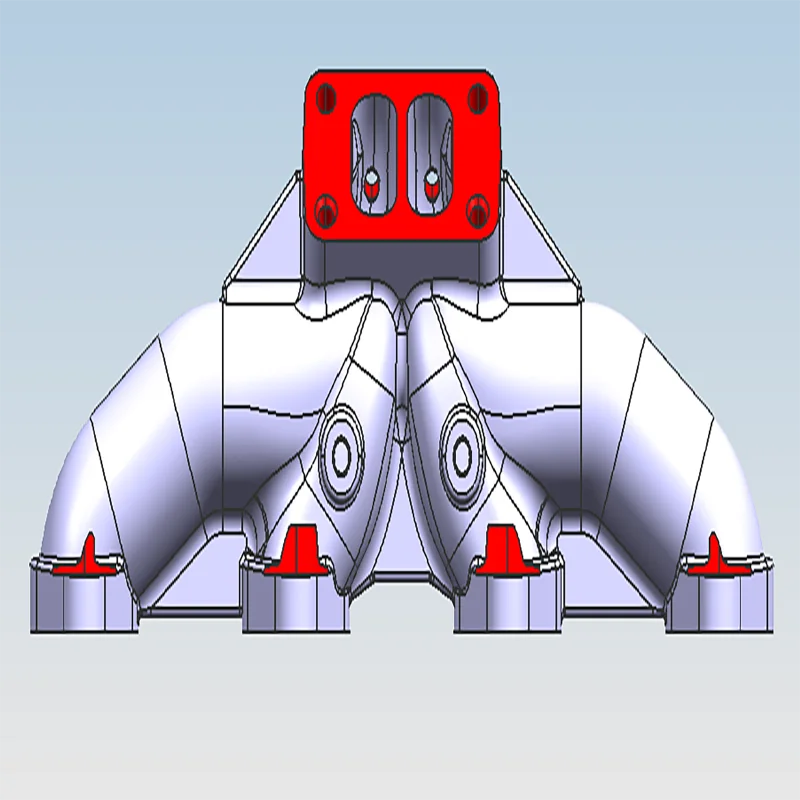

Process designs derive from engineering drawings

3D scanners

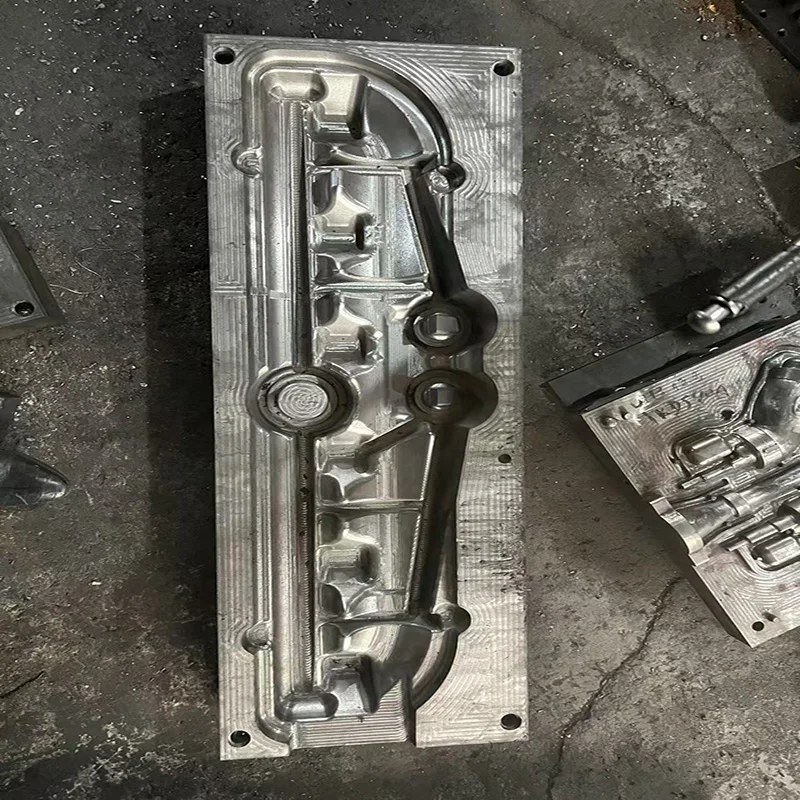

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control