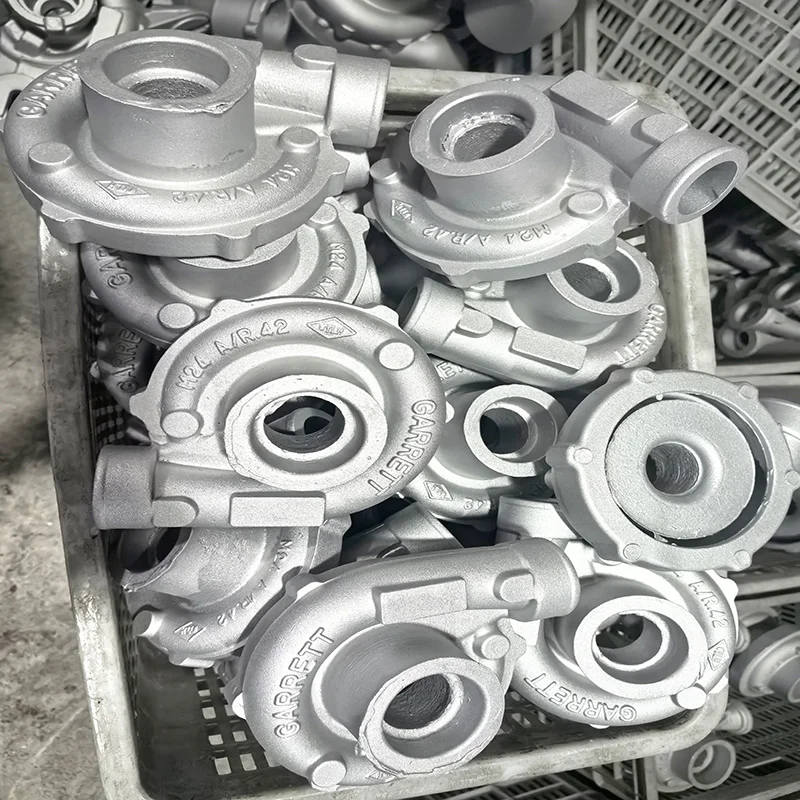

Industrial Low-Pressure Die Casting Aluminum Parts Aluminum Alloy From Aluminum Casting Services

- Overview

- Recommended Products

For industrial applications demanding superior metal integrity and complex geometries, Low-Pressure Die Casting (LPDC) stands as a premier manufacturing process. Our specialized Aluminum Casting Services utilize this advanced technique to produce high-performance Aluminum Alloy parts that excel in structural strength, pressure tightness, and dimensional consistency. This method is engineered for components where reliability is non-negotiable, offering a perfect balance between the high volume of traditional die casting and the superior quality of gravity casting.

Premium Aluminum Alloys for Enhanced Performance

We employ high-strength, heat-treatable aluminum alloys such as A356.2 and A357, which are ideally suited for the low-pressure process. These alloys are selected for their exceptional combination of properties:

High Strength-to-Weight Ratio: Provides significant weight savings without compromising structural integrity, crucial for fuel efficiency and handling in mobile equipment.

Excellent Corrosion Resistance: Inherently withstands harsh environmental and operational conditions, ensuring long-term durability.

Superior Mechanical Properties: After a full T6 heat treatment, these alloys achieve high tensile strength, yield strength, and elongation, making them suitable for highly stressed components.

Good Machinability and Weldability: Allows for easy secondary processing and repairs, adding to the component's versatility and service life.

The Low-Pressure Die Casting Advantage

Our LPDC process involves forcing molten aluminum upward into a steel die under controlled, low pressure. This method offers distinct advantages over other casting techniques:

Denser Microstructure: The laminar, bottom-up fill minimizes turbulence and air entrapment, resulting in parts with exceptionally low porosity. This enhances mechanical properties and ensures leak-proof performance for pressurized applications.

Enhanced Metallurgical Quality: Controlled solidification under pressure yields a finer grain structure, improving the part's overall strength and fatigue resistance.

Superior Dimensional Accuracy and Surface Finish: The process produces parts with excellent as-cast surfaces and tight tolerances, reducing the need for extensive secondary machining.

Higher Yield and Efficiency: The integrated feeding system reduces scrap material, making the process both cost-effective and high-quality.

Comprehensive Secondary Processing

Our service is fully integrated, offering precision CNC machining, heat treatment (T5/T6 temper), and a range of finishing options, including shot blasting, anodizing, and powder coating, to deliver parts that are ready for immediate assembly.

Proven Industrial Applications

Our aluminum LPDC parts are critical in demanding sectors such as:

Automotive & Commercial Vehicles: Wheels, suspension control arms, and brake calipers.

Aerospace & Defense: Housings, brackets, and structural components.

Electrical Enclosures: Leak-proof, EMI/RFI shielded housings for sensitive equipment.

Hydraulic & Pneumatic Systems: Valve bodies, manifolds, and compressor parts.

Partner with our aluminum casting services for industrial components that define reliability. Our low-pressure die casting expertise delivers the structural perfection and leak-free integrity your most critical applications require.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |