In today's advanced manufacturing landscape, the demand for complex, high-tolerance aluminum components continues to grow across industries. Our integrated High Precision Custom Aluminum CNC Machining Milling and Casting Parts Services provide a comprehensive manufacturing solution that combines the design flexibility of casting with the exceptional accuracy of CNC machining. This dual-capability approach enables us to deliver components with optimal mechanical properties, complex geometries, and tight tolerances for the most demanding applications.

Advanced Material Selection

We work with a comprehensive range of aluminum alloys to meet specific performance requirements:

A356-T6: Excellent castability with tensile strength of 230 MPa and yield strength of 165 MPa

6061-T6: Superior machinability with tensile strength of 310 MPa and elongation of 12%

7075-T6: High strength-to-weight ratio with tensile strength of 570 MPa

A380: Outstanding fluidity for complex thin-walled castings

All materials undergo rigorous certification and testing to ensure consistent mechanical properties and chemical composition compliance with ASTM and ISO standards.

Integrated Manufacturing Process

Our unique combination of casting and machining capabilities provides significant advantages:

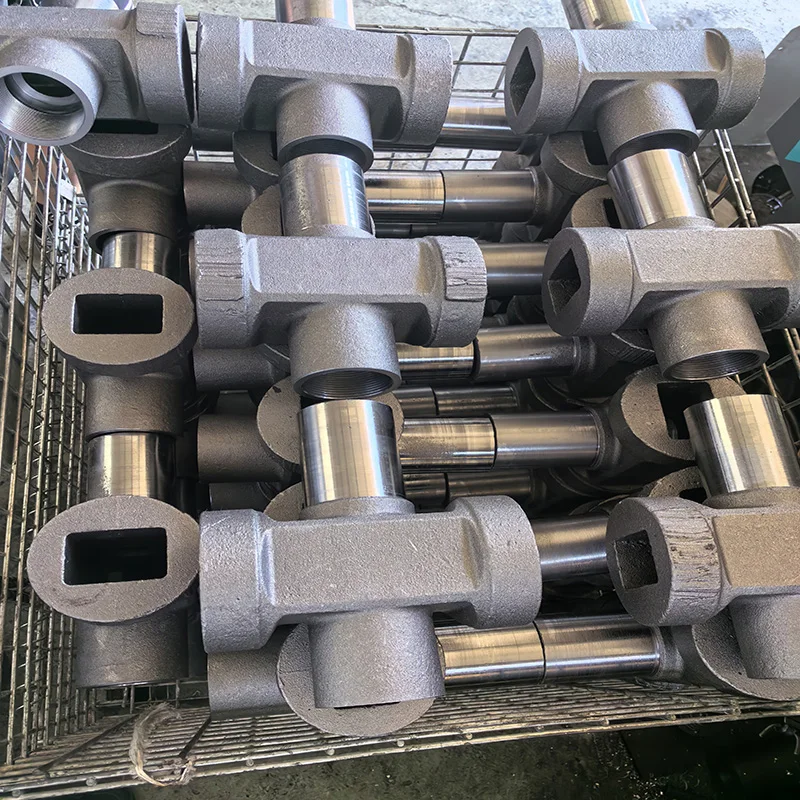

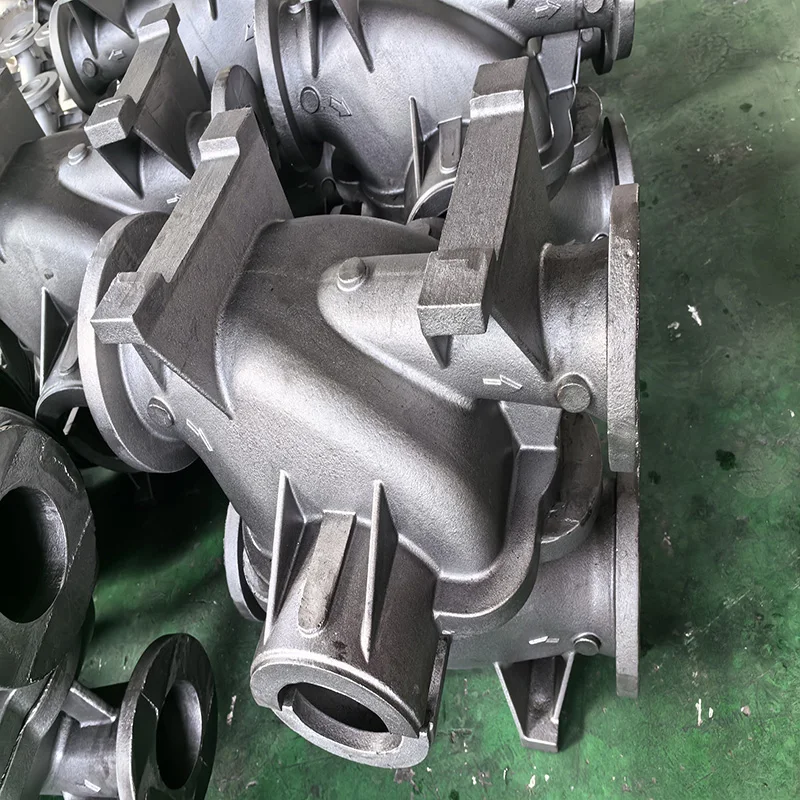

Precision Casting Phase

Investment casting for complex geometries with ±0.005 in/in tolerances

Permanent mold casting for superior mechanical properties

3D printed sand molds for rapid prototyping and complex internal features

Controlled solidification monitoring ensuring dense, pore-free structures

CNC Machining Phase

5-axis simultaneous machining for complex contours and angles

High-speed milling (15,000+ RPM) for optimal surface finishes

Precision boring and threading with positional accuracy ±0.01mm

CMM inspection integrated throughout the machining process

Performance Characteristics

Our aluminum components deliver:

Dimensional tolerances to IT7-8 grade

Surface finishes from Ra 0.8 to 3.2 μm

Weight reduction up to 60% compared to steel components

Excellent corrosion resistance and thermal conductivity

High strength-to-weight ratios for performance-critical applications

Quality Assurance and Certification

Our integrated quality system includes:

First article inspection with comprehensive documentation

Statistical process control throughout manufacturing

Material traceability with full certification

Non-destructive testing (X-ray, dye penetrant)

ISO 9001:2015 and AS9100 certified processes

Technical Applications

Our services support diverse industries including:

Aerospace: Structural components, brackets, and housings

Automotive: Engine parts, intake manifolds, and suspension components

Medical: Surgical instruments, device housings, and imaging equipment

Robotics: Actuator housings, mounting brackets, and structural frames

Defense: Weapon components, communication housings, and optical mounts

By combining casting and machining expertise, we optimize each manufacturing process to deliver components that maximize performance while minimizing cost and lead time. Our engineering team works collaboratively with clients from design through production, ensuring manufacturability, functionality, and reliability in every component we deliver.