- Overview

- Recommended Products

Advanced Casting Solutions for Industrial Applications

Our foundry specializes in grey iron casting using both green sand and resin sand molding technologies, delivering high-quality components for diverse industrial sectors. With extensive expertise in ferrous metallurgy and mold engineering, we provide comprehensive casting solutions that balance performance requirements with cost-effectiveness, maintaining strict quality standards throughout our manufacturing processes.

Material Excellence and Performance Characteristics

We utilize premium grey iron grades (G2500 to G4000) specifically selected for their exceptional mechanical properties and casting performance. The graphite flake structure inherent in grey iron provides superior vibration damping capacity - up to 25 times greater than steel - making it ideal for machine bases and engine components. Our castings demonstrate excellent compressive strength, reaching 100-150 ksi, while maintaining good machinability due to the self-lubricating properties of graphite. The thermal conductivity of our grey iron components ensures stable performance under thermal cycling conditions, with wear resistance that outperforms many alternative materials in abrasive environments.

Green Sand Casting Technology

Our automated green sand casting lines employ bentonite-clay bonded molds with precisely controlled moisture content and compaction strength. This process delivers:

High production efficiency with cycle times under 60 seconds

Consistent mold hardness between 85-95 scale units

Reduced gas defects through optimized venting systems

Cost-effective manufacturing for medium to high volume orders

The versatility of green sand casting allows production of components weighing from 1kg to 500kg, maintaining dimensional tolerances within ISO CT10-13 grades.

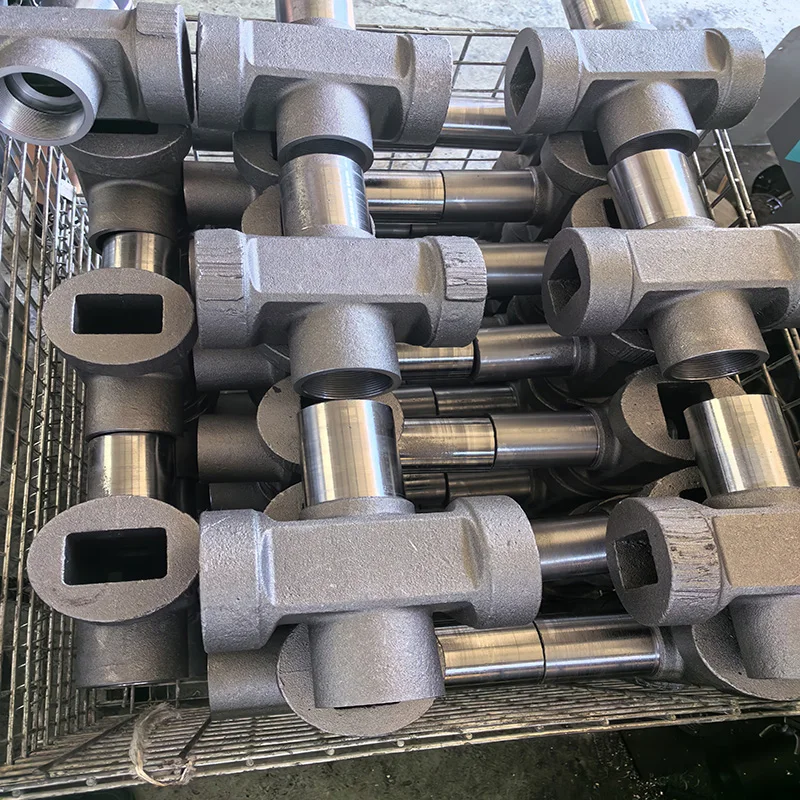

Resin Sand Casting Precision

For components requiring superior surface finish and dimensional accuracy, we employ resin-bonded sand systems including:

Phenolic urethane cold box process for complex cores

Furan no-bake systems for large mold assemblies

Alkaline phenolic systems for reduced emissions

This advanced molding technology enables:Enhanced dimensional stability with tolerances to CT8-10

Superior surface finish achieving Ra 12.5-25 μm

Reduced cleaning and machining requirements

Capability for castings up to 3000kg in weight

Comprehensive Quality Assurance

Our integrated quality management system ensures component reliability through:

Spectrochemical analysis for precise chemistry control

Ultrasonic testing for internal integrity verification

Real-time process monitoring and data recording

Full material traceability from raw material to finished casting

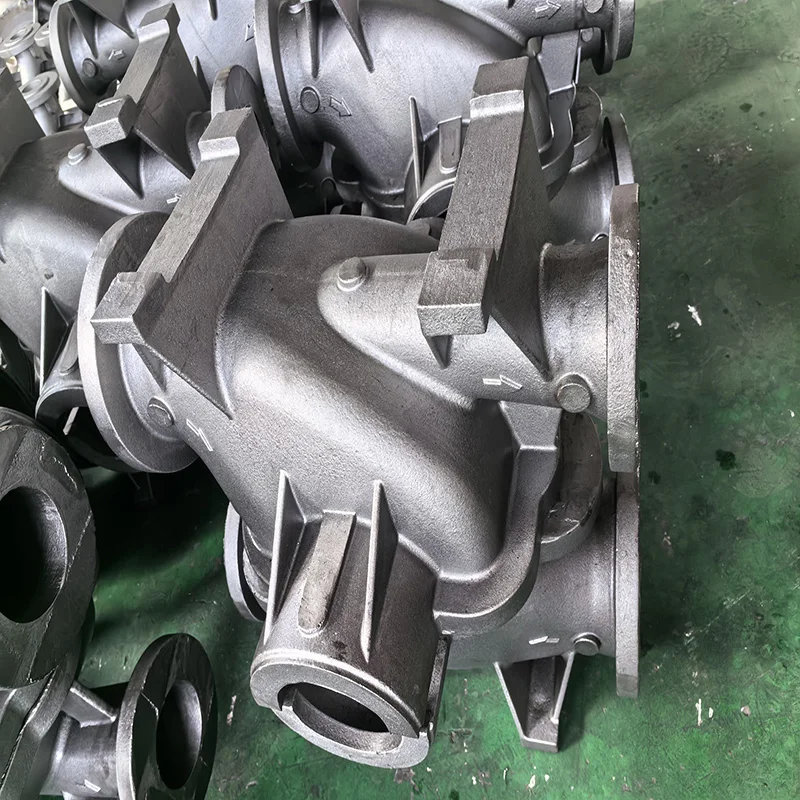

Industrial Application Expertise

Our grey iron castings serve critical functions across multiple industries:

Automotive: brake discs, engine blocks, and transmission cases

Machinery: pump housings, gearboxes, and machine tool bases

Power generation: compressor bodies and turbine housings

Agricultural: implement parts and equipment frames

Technical Specifications

Casting size range: 1kg - 3000kg

Dimensional tolerance: CT8-13 per ISO 8062

Surface roughness: Ra 12.5-50 μm

Lead time: 3-6 weeks based on complexity

Annual capacity: 15,000 tons

By leveraging our dual-molding capabilities and grey iron expertise, we deliver casting solutions that optimize performance, durability, and value for industrial applications worldwide. Our engineering team provides comprehensive technical support from design through production, ensuring components meet exact specifications while maintaining competitive pricing in global markets.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |