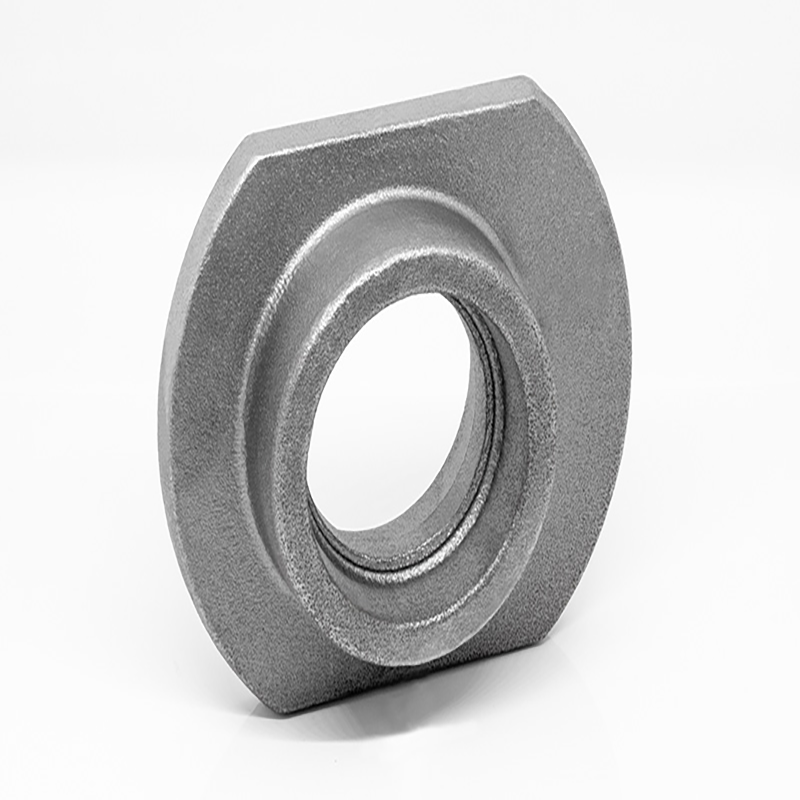

Introducing, Pengxin's hot forging service for customized steel auto parts! Our forged parts are meticulously crafted using high-quality materials and cutting-edge technology to meet the specific needs of your vehicle. Say goodbye to generic auto parts and experience the superior performance and durability of Pengxin's hot forged components.

At Pengxin, we understand the importance of precision and reliability when it comes to auto parts. That's why our team of skilled craftsmen utilize the hot forging process to create parts that are strong, durable, and perfectly tailored to your vehicle. Whether you need custom suspension components, engine parts, or any other auto part, Pengxin has got you covered.

Our hot forging service involves heating steel to a high temperature and then shaping it using a forging press. This process results in parts that are incredibly strong and resistant to wear and tear. By choosing Pengxin for your hot forging needs, you can rest assured that you are getting top-quality parts that will last for years to come.

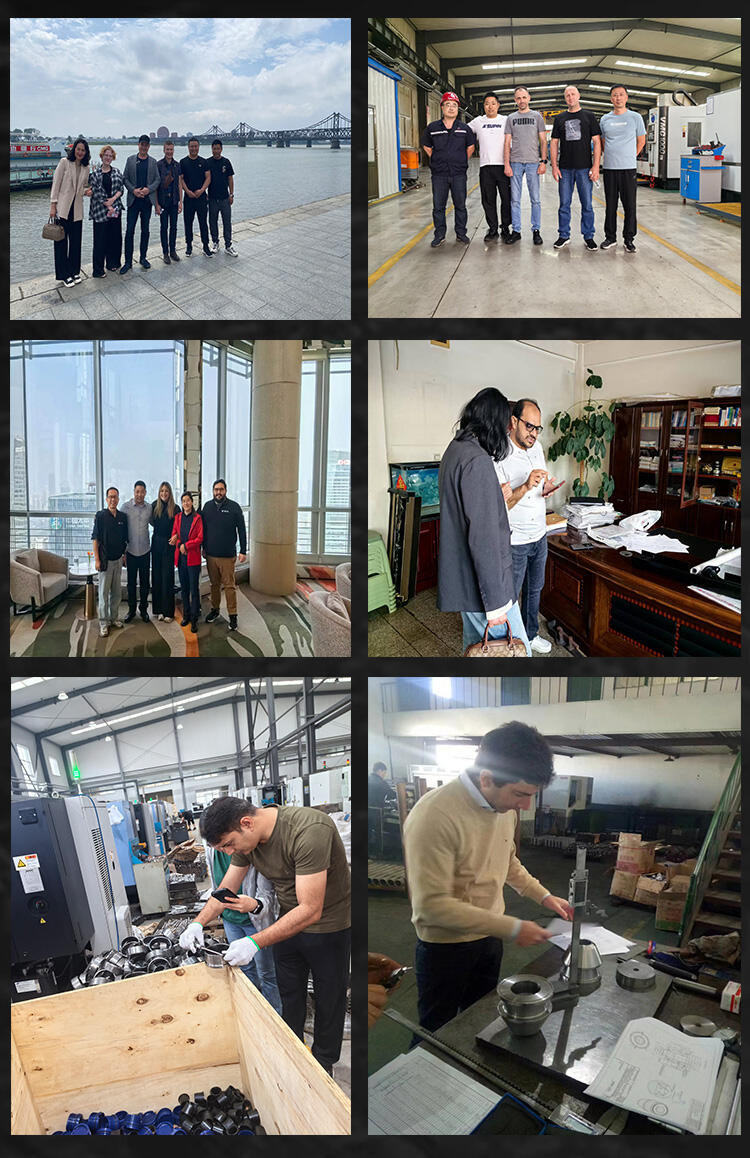

What sets Pengxin apart from other hot forging services is our dedication to customization. We work closely with our customers to understand their unique requirements and preferences, ensuring that the final product meets their exact specifications. Whether you need a one-of-a-kind component or a large batch of parts, Pengxin can deliver exactly what you need.

In addition to our focus on customization, Pengxin is also committed to providing exceptional customer service. From the moment you contact us to the final delivery of your forged parts, our team is here to answer any questions and address any concerns you may have. We strive to make the hot forging process as smooth and stress-free as possible for our customers.

So, why settle for off-the-shelf auto parts when you can have custom-forged components that are perfectly suited to your vehicle? Choose Pengxin for all your hot forging needs and experience the difference that quality craftsmanship and personalized service can make. Upgrade your vehicle with Pengxin's forged parts today

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvanized etc |

|

|

|

Size |

Customized |

|

|

|

Surface treatment |

Powder coating, electroplating, oxide, anodization |

|

|

|

Technics |

laser cut, bend, weld, stamp, casting, forging |

|

|

|

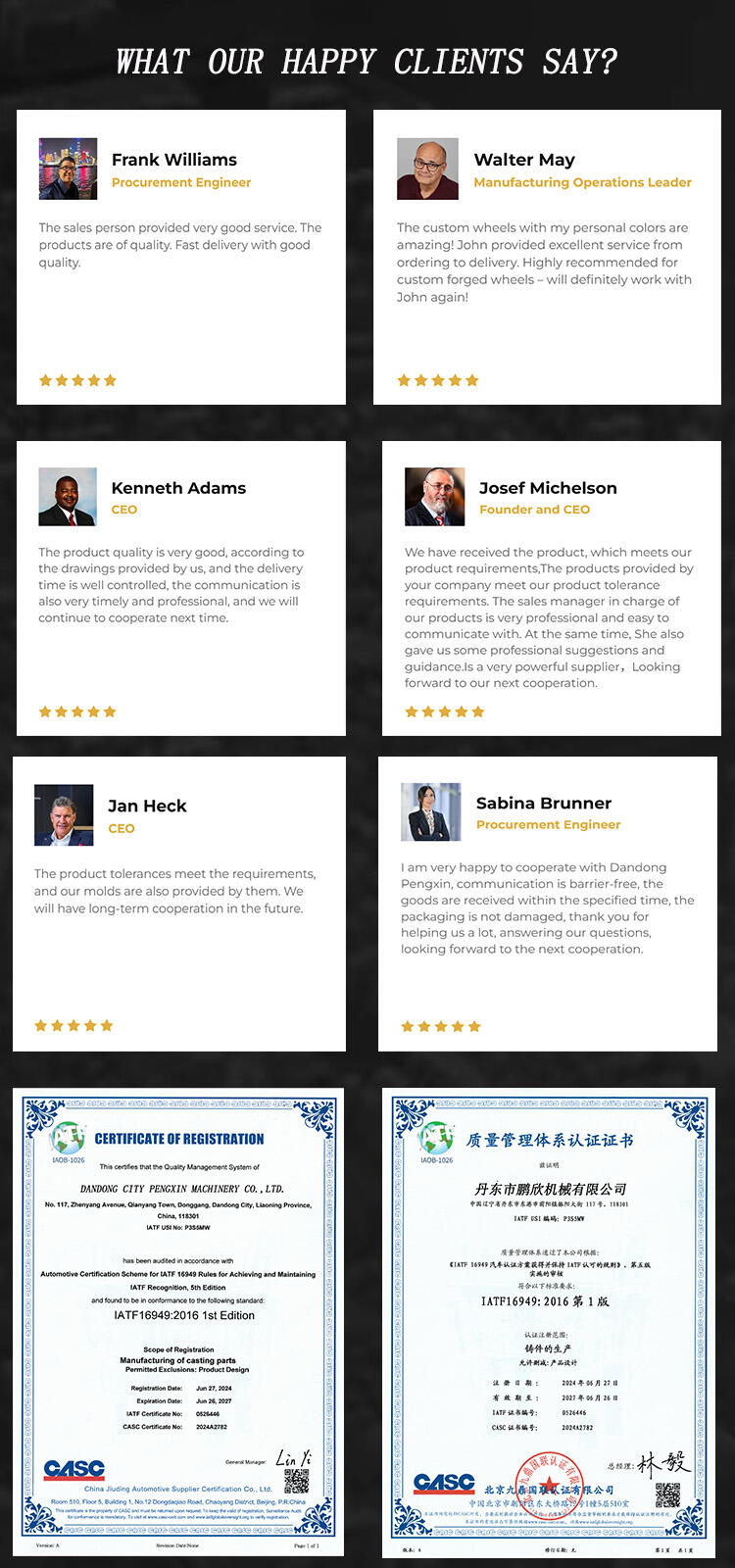

Certification |

ISO9001:2015 |

|

|

|

OEM |

Accept |

|

|

|

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

|

|

|

Color |

Customized |

|

|

|

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

|

|

|

Who We Are

Dandong Pengxin Machinery Co., Ltd., founded in 1958, is a private enterprise specializing in casting, machining, and assembly

Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons

Equipped with advanced technologies like high-pressure molding and Japanese FBO Ⅲ production lines, it produces up to 30,000 tons/year. Facilities include 12-pulse electronic furnaces, CNC machines, and a quality inspection center with precision instruments

Pre-sales

Get your purchasing needs → Confirm order drawing→ Give customized solution → Offer a quotation → Make the pattern→ Provide samples→ Bulk production after samples approve the test

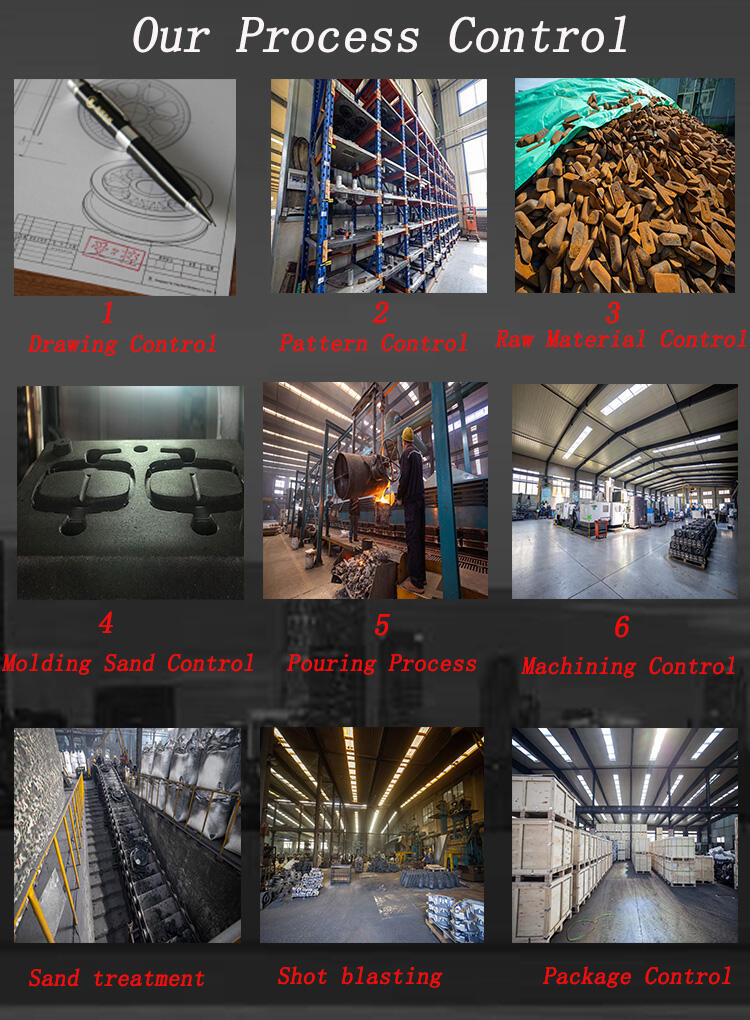

On Sale

Drawing Control → Pattern Control → Raw Material Control → Molding Sand Control → Pouring Process Control → Raw Casting & Machining Control →Other Requirement Control→ Packing & Delivery Control

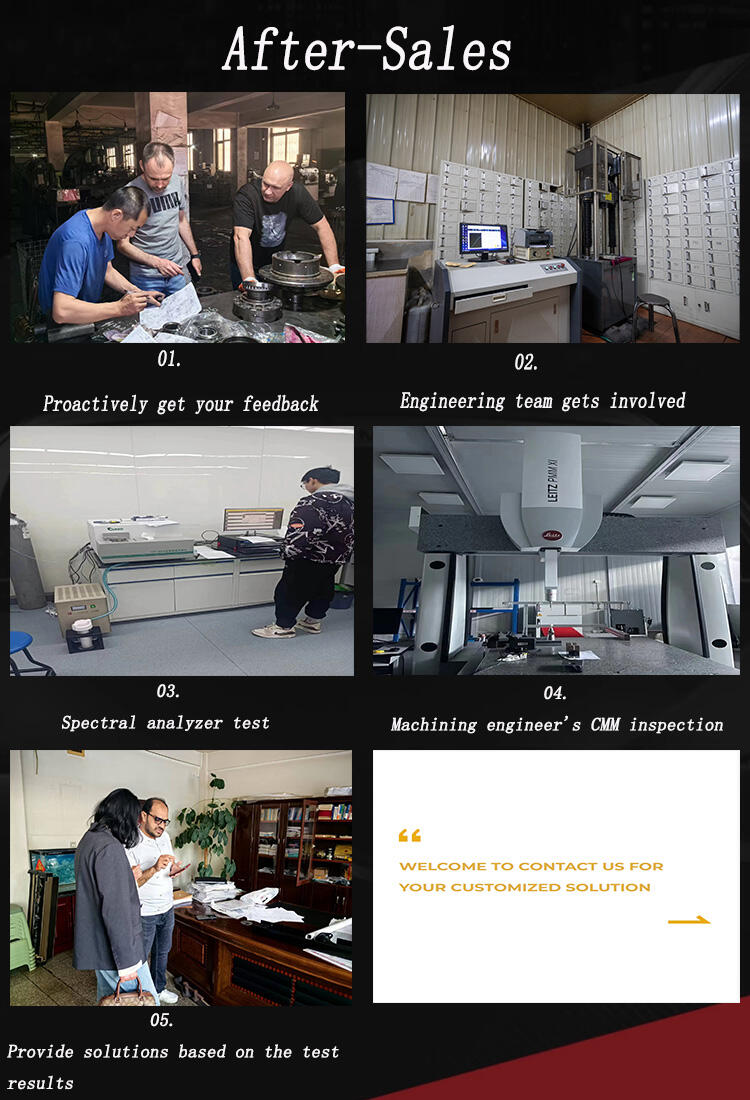

After-Sales

Proactively get your feedback→ Engineering team gets involved→Casting engineer conducts metallographic and spectral tests based on the inventory test rods→Machining engineer's CMM inspection is based on the inventory samples→Provide solutions based on the test results→Welcome to contact us for your customized solution

R&D

Our Company Owns A Provincial Level Technology Center, Plus A 15 Person R&D Team, With average 20+ Years Of R&D Experience. We can help customers design for free according to their requirements, or produce according to the drawings or samples

Production Capacity

100,000 tons+Annual production capacity for Iron

30,000 tons+Annual production capacity for Aluminum

80,000 tons+Annual production capacity for Steel

4000+Mold develop production

Quality Control

At Pengxin-Casting, process control begins as early as in the planning and development phase of the products. We support our customers to perform all required tests and inspections in a laboratory. It goes without saying that our plants are certified according to ISO 9001 and IATF16949 in line with a validated quality management. As we strive to accomplish our zero-error policy, you can rely on the following process control measures: Drawing Control → Pattern Control → Raw Material Control → Molding Sand Control → Pouring Process Control → Raw Casting & Machining Control →Other Requirement Control→ Packing & Delivery Control

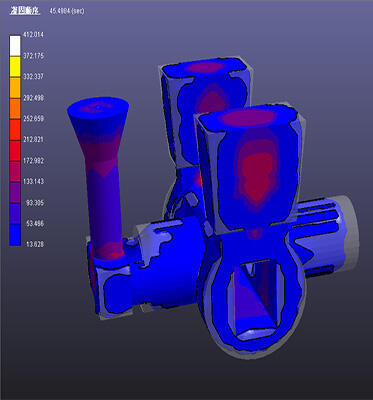

Pattern Control

We simulate feeding system to check the pattern design from the filling process and material solidification. In this way, we can shorten the mold development cycle, reduce the number of mold trials and improve product quality. The software we use includes Abaqus, Mold flow and Moldex3D, simulate feeding system, reduce casting defects and improve efficiency

Raw Material Control

We check the chemistry property as new raw material coming

Raw Casting & Machining Control

All dimensions 100% measuring

Raw material spectral analysis and X-ray detection Critical dimensions with CMM measuring