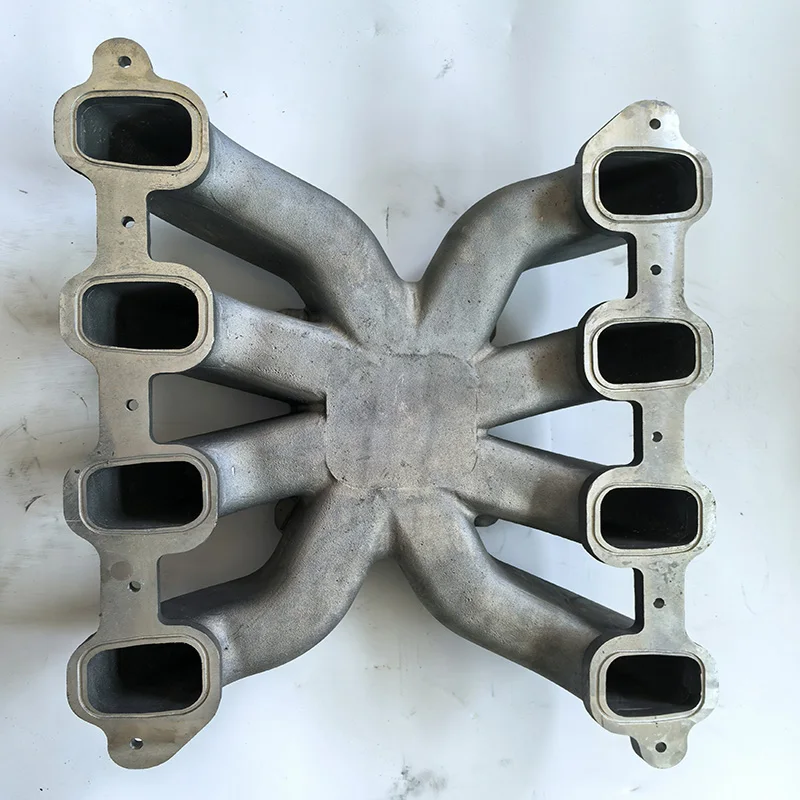

For automotive engineers and performance enthusiasts seeking optimal airflow and engine efficiency, the intake manifold is a critical component. Our China-based manufacturing specializes in producing high-performance Aluminum Intake Manifolds using the gravity casting process, delivering an exceptional balance of strength, thermal management, and cost-effectiveness for both OEM and aftermarket applications.

Premium Material: A356-T6 Aluminum Alloy

We utilize A356 aluminum alloy, the industry standard for high-integrity castings, followed by a T6 heat treatment. This specific alloy offers an excellent combination of strength, corrosion resistance, and most importantly, outstanding castability. The T6 temper (solution heat treatment and artificial aging) significantly enhances the material's tensile strength and yield strength, ensuring the manifold can withstand the under-hood environment, including vibration and thermal cycling. Its low density contributes to overall vehicle weight reduction, while its superior thermal conductivity compared to composite materials helps reduce heat soak, maintaining a denser air charge for potential power gains.

Precision Gravity Casting Process

Our manufacturing leverages the gravity casting (permanent mold casting) process. This technique involves pouring molten A356 aluminum into a reusable steel mold under the force of gravity. It represents the optimal compromise between cost, production speed, and part quality. Compared to high-pressure die casting, gravity casting produces parts with a denser, more homogeneous microstructure that is virtually free of porosity, resulting in superior strength and pressure tightness—a critical factor for an intake manifold. The process allows for the creation of complex internal runners and external features with excellent dimensional accuracy and surface finish, requiring minimal secondary machining.

Performance and Application

These manifolds are designed to deliver:

Optimized Airflow: Smooth, consistent internal runner walls minimize turbulence for improved volumetric efficiency.

Enhanced Durability: The robust A356-T6 construction resists cracking and degradation from under-hood heat and vibration.

Weight Reduction: Aluminum construction is significantly lighter than traditional cast iron counterparts.

Our intake manifolds serve a wide range of applications, including:

Performance Upgrades for gasoline and diesel engines.

OEM Replacement for a variety of passenger and commercial vehicles.

Custom Projects for racing, marine, and industrial engines.

By choosing our China-manufactured gravity cast intake manifolds, you secure a reliable, high-performance component that enhances engine breathing and durability, backed by efficient production and stringent quality control.

About Us