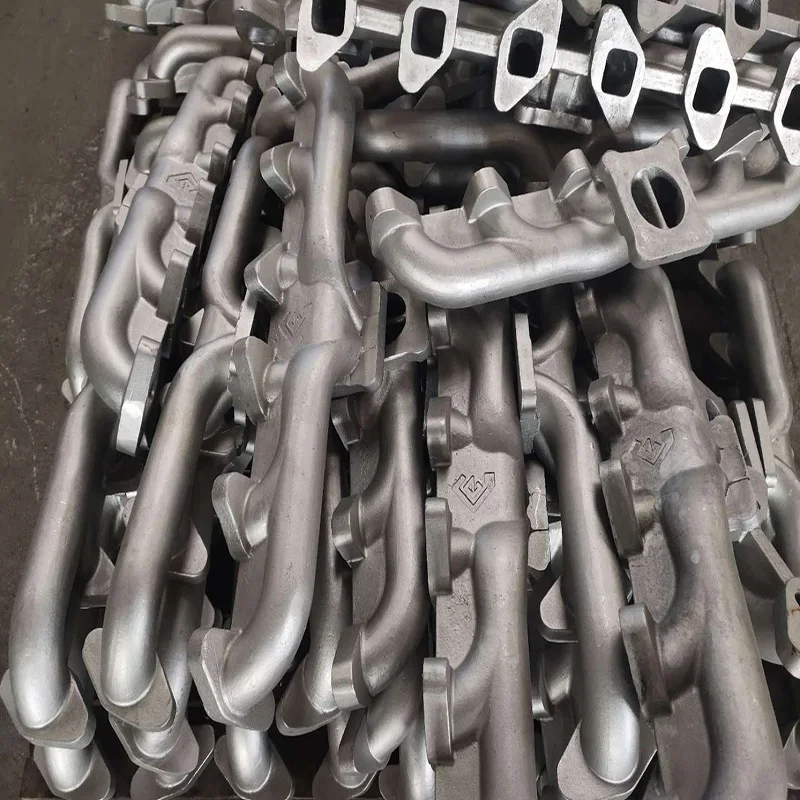

Custom Metal Casting Service-Stainless Steel Precision Pull-up Cleat Lost Wax Casting for Marine Parts

- Overview

- Recommended Products

As a specialized marine component manufacturer, we provide precision stainless steel casting services specifically engineered for demanding marine applications. Our custom pull-up cleats manufactured through advanced lost wax casting technology represent the pinnacle of marine hardware engineering, combining superior corrosion resistance with exceptional mechanical strength for lifelong performance in saltwater environments.

Marine-Grade Material Selection

We exclusively utilize 316/L stainless steel for marine casting applications, recognized as the industry standard for superior saltwater corrosion resistance. This austenitic chromium-nickel stainless steel contains molybdenum (2-3%), significantly enhancing its resistance to chloride pitting and crevice corrosion. The material demonstrates:

Tensile strength: 515-690 MPa

Yield strength: 205 MPa minimum

Excellent impact toughness at low temperatures

Superior resistance to stress corrosion cracking

Advanced Lost Wax Casting Process

Our investment casting methodology ensures precision marine components with exceptional dimensional accuracy and surface quality:

Pattern Development

We create injection-molded wax patterns using aluminum molds designed with precise shrinkage allowances. Each pattern undergoes meticulous inspection to ensure dimensional conformity before the ceramic coating process.

Ceramic Shell Building

Multi-layer ceramic shell construction creates robust molds capable of withstanding the high pouring temperatures of stainless steel. This process ensures:

Superior surface finish quality (Ra 3.2-6.3 μm)

Tight dimensional tolerances (±0.13 mm per 25 mm)

Accurate reproduction of complex geometries

Precision Casting and Finishing

Our controlled melting and pouring operations maintain optimal metal temperature and chemistry. Post-casting processes include:

CNC machining of critical mounting surfaces

Precision thread tapping for mounting hardware

Electropolishing for enhanced corrosion resistance

Passivation treatment to maximize corrosion resistance

Performance Characteristics

Our marine pull-up cleats deliver uncompromising performance:

Safety Factor: 5:1 safety margin exceeding marine industry standards

Corrosion Resistance: Withstands 1000+ hours salt spray testing

Load Capacity: Rated for 1000-5000 kg working loads depending on size

Cyclic Testing: Endures 10,000+ operational cycles without failure

UV Resistance: Maintains structural integrity under prolonged sun exposure

Quality Assurance Protocol

Every cleat undergoes rigorous validation:

Material certification to ASTM A743 standards

Liquid penetrant testing for surface defects

Dimensional verification against marine industry drawings

Load testing to validate working and ultimate strength

Corrosion testing in simulated marine environments

Marine Applications

Our stainless steel cleats serve critical functions across marine sectors:

Recreational Boating: Deck hardware for sailboats and powerboats

Commercial Marine: Heavy-duty cleats for workboats and fishing vessels

Marina Infrastructure: Dock cleats and mooring hardware

Naval Architecture: Military-specification marine hardware

By combining marine-grade materials with precision lost wax casting technology, we deliver pull-up cleats that withstand the harshest marine environments while maintaining flawless operation throughout their service life. Our engineering team understands the critical nature of marine hardware and ensures every component meets or exceeds international marine safety standards.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |