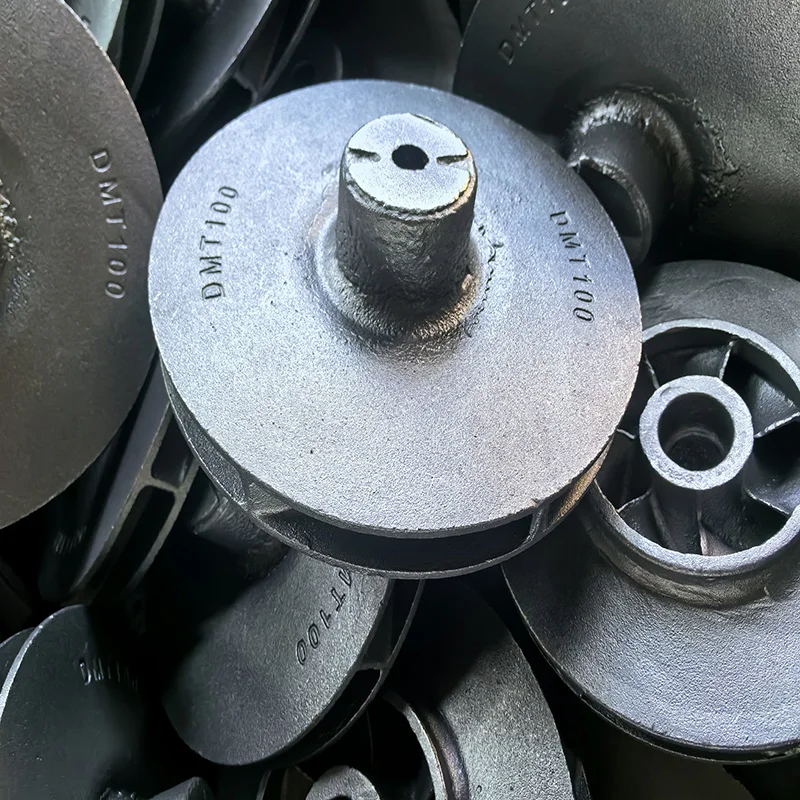

Custom Ductile Iron Castings Sand Casting Grey Iron Shelf Brackets for Machinery Parts High Quality Manufacturer Product

- Overview

- Recommended Products

Precision Engineered Support Solutions for Industrial Applications

As a high-quality manufacturer, we specialize in producing custom ductile iron castings and grey iron shelf brackets through advanced sand casting processes. These critical support components are engineered to provide reliable performance in machinery applications where strength, durability, and precision are essential for operational safety and efficiency.

Advanced Material Technology

Our manufacturing utilizes superior iron grades tailored for specific application requirements:

Ductile Iron Specifications

Grade 65-45-12: Yield strength 275 MPa, tensile strength 450 MPa, 12% elongation

Grade 80-55-06: Enhanced strength with 415 MPa yield, 550 MPa tensile strength

Grade 100-70-03: High-strength formulation for demanding applications

Grey Iron Excellence

Class 30 (G3000): Optimal vibration damping and compression resistance

Class 35 (G3500): Enhanced strength for heavy-load applications

Class 40 (G4000): Premium grade for critical structural components

All materials feature controlled microstructure and undergo rigorous metallurgical testing to ensure consistent mechanical properties and performance reliability.

Enhanced Performance Characteristics

Superior Load Capacity: Safe working load ratings from 500kg to 5000kg per bracket

Excellent Vibration Damping: 5-7 times better vibration absorption than steel equivalents

Impact Resistance: Charpy impact values of 10-15 Joules at room temperature

Corrosion Resistance: Natural protection enhanced with various coating options

Thermal Stability: Maintains mechanical properties from -40°C to 200°C

Fatigue Strength: Designed for minimum 1 million load cycles at maximum capacity

Precision Manufacturing Process

Our integrated sand casting system ensures exceptional quality:

Pattern Development

CNC-machined patterns with precise draft angles and shrinkage allowances

3D printed rapid prototypes for design validation

Modular pattern systems for custom bracket configurations

Sand Casting Excellence

Resin-bonded sand molding ensuring dimensional accuracy

Automated molding lines maintaining consistent mold hardness (85-95 scale)

Controlled pouring temperature management (±15°C)

Real-time solidification monitoring

Quality Manufacturing

Automated shakeout and cleaning systems

Precision machining of mounting surfaces and holes

Shot blasting for superior surface finish

Comprehensive heat treatment options

Quality Assurance Protocol

100% dimensional verification using CMM systems

Ultrasonic testing for internal integrity

Load testing to 1.5 times rated capacity

Surface quality inspection per ISO 8501

Material certification including mechanical testing

Technical Specifications

Bracket sizes: 150mm to 1200mm length capacity

Load ratings: 500kg to 5000kg per bracket

Dimensional tolerance: CT9-CT12 per ISO 8062

Surface finish: Ra 12.5-25 μm as-cast

Lead time: 3-5 weeks for production orders

Industrial Applications

Heavy machinery support systems

Industrial shelving and storage solutions

Equipment mounting and framing

Conveyor system supports

Manufacturing cell structures

Competitive Advantages

30+ years industrial casting expertise

Complete in-house design and engineering

Custom solutions for unique applications

Flexible production volumes

Global quality certifications

Our custom iron castings represent the perfect combination of material science and manufacturing precision, delivering shelf brackets that ensure reliable performance in the most demanding industrial environments. The superior mechanical properties and rigorous quality control guarantee components that provide lasting support and safety for machinery applications worldwide.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |