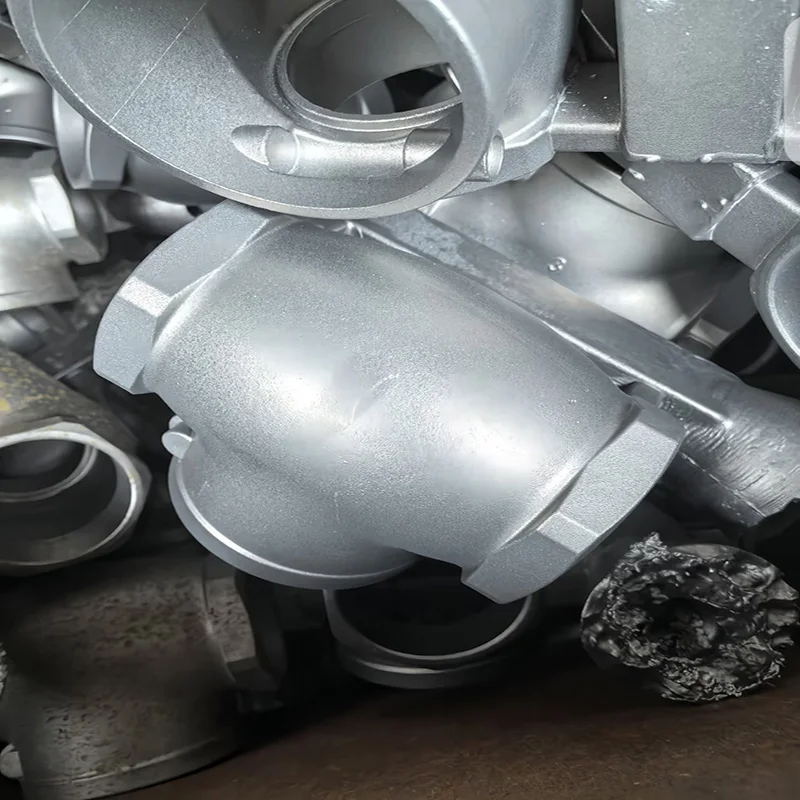

In industries requiring exceptional corrosion resistance and complex geometry capabilities, 316 stainless steel stands as the material of choice for demanding applications. Our Custom 316 Stainless Steel Lost Wax Investment Casting Services deliver precision components that combine superior material properties with the dimensional accuracy of advanced investment casting technology. This integrated manufacturing approach provides optimal solutions for critical applications in marine, chemical processing, medical, and food processing industries.

Premium Material: 316 Stainless Steel

316 stainless steel represents the superior grade in the austenitic stainless steel family, characterized by:

Enhanced corrosion resistance due to 2-3% molybdenum content

Excellent resistance to pitting and crevice corrosion in chloride environments

High tensile strength (515 MPa min) and yield strength (205 MPa min)

Good elevated temperature strength and oxidation resistance

Superior formability and weldability compared to standard stainless grades

The alloy's chemical composition typically includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, creating an optimal balance between mechanical properties and corrosion resistance for severe service conditions.

Advanced Lost Wax Investment Casting Process

Our manufacturing employs sophisticated investment casting technology:

Pattern and Mold Fabrication

Injection molded wax patterns using aluminum dies

Ceramic shell building with silica sol binder system

Multi-layer coating process achieving shell thicknesses of 10-15mm

Controlled humidity and temperature during drying cycles

Casting Operations

Induction melting under controlled atmosphere

Precision pouring temperature control (1500-1550°C)

Computerized solidification monitoring

Automated shell removal and cut-off operations

Precision Engineering Capabilities

Our investment casting process delivers:

Dimensional tolerances of ±0.005 inches per inch

Surface finishes of 125-250 microinches as-cast

Minimum wall thickness capabilities of 0.040 inches

Weight range from ounces to 50 pounds per piece

Complex internal passages and intricate geometries

Performance Characteristics

316 stainless steel investment castings provide:

Excellent corrosion resistance in acidic and alkaline environments

Good mechanical properties at both high and low temperatures

Pressure tightness suitable for hydraulic and pneumatic applications

Biocompatibility for medical and food contact applications

Long-term performance in marine and chemical environments

Quality Assurance Protocol

Each casting undergoes comprehensive validation:

Liquid penetrant testing for surface defect detection

Radiographic examination for internal quality assurance

Chemical analysis verification using optical emission spectroscopy

Mechanical testing including tensile and hardness tests

Dimensional inspection using coordinate measuring machines

Technical Applications

Our services cater to diverse industries including:

Marine components: Pump impellers, valve bodies, fittings

Chemical processing: Reactor parts, mixer components, vessel internals

Medical devices: Surgical instruments, implantable device components

Food processing: Equipment parts, mixing blades, valve components

Pharmaceutical: Process equipment, vessel components, transfer parts

Our engineering team provides complete technical support from design optimization through production, ensuring each component meets specific application requirements for corrosion resistance, mechanical strength, and service life. By combining advanced investment casting technology with premium 316 stainless steel, we deliver components that ensure reliable performance in the most demanding corrosive environments while maintaining cost-effectiveness through near-net-shape manufacturing.

About Us