- Overview

- Recommended Products

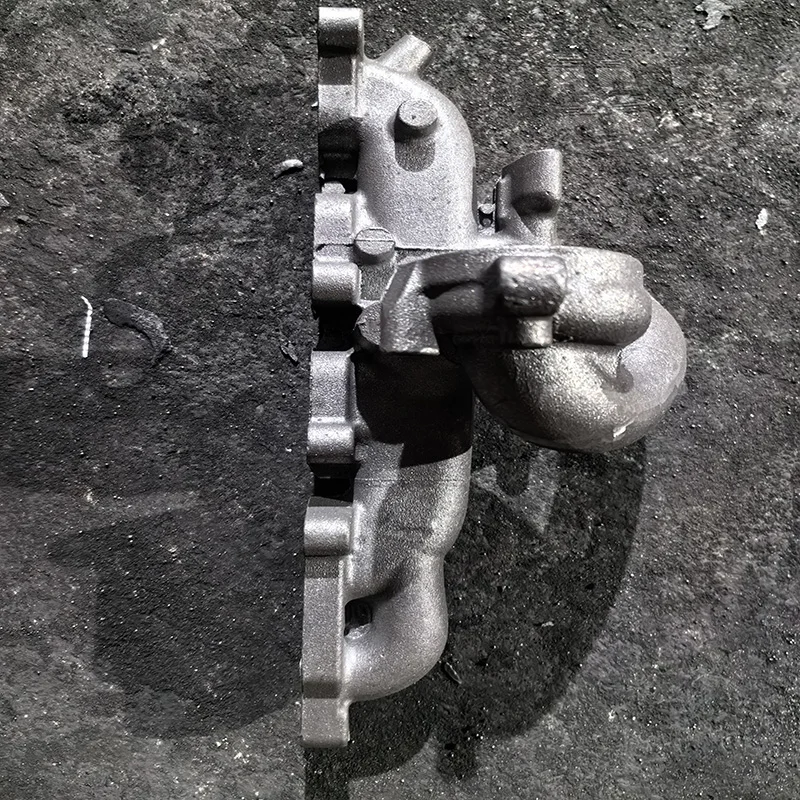

The exhaust manifold is a critical engine component, responsible for channeling hot exhaust gases away from the combustion chambers. For Honda Civic owners seeking reliability and enhanced performance, the 06180RBDE01 Exhaust Manifold represents a direct-fit solution built to meet rigorous standards. This article explores the key features—from materials to manufacturing—that make this component a professional-grade choice.

Advanced Material for Superior Heat Management

At the core of the 06180RBDE01 manifold's reliability is its construction material. Typically manufactured from high-grade cast iron or stainless steel, it is engineered to withstand extreme thermal cycling and corrosive exhaust gases. Cast iron offers excellent durability and heat retention, which can aid in faster catalyst warm-up, while stainless steel variants provide superior resistance to oxidation and corrosion over the long term. This careful material selection ensures the manifold maintains structural integrity under the high-stress environment of the engine bay, preventing warping or cracking.

Precision Manufacturing and Design

The production of this manifold involves sophisticated casting techniques to create precise, smooth-walled runner passages. This precision is crucial for minimizing exhaust flow restrictions, reducing backpressure, and allowing the engine to expel gases more efficiently. A design that promotes smooth laminar flow directly contributes to engine breathing, which can support marginal gains in horsepower and torque. Furthermore, the flange surfaces are machined to exact specifications, guaranteeing a perfect seal against the cylinder head to prevent exhaust leaks—a common issue with inferior aftermarket parts.

Performance and Compatibility

The 06180RBDE01 is designed as an OEM-replacement part, ensuring perfect compatibility with specific Honda Civic models. Its direct-fit design simplifies installation, saving on labor time and cost. By maintaining optimal exhaust scavenging, this manifold helps the engine operate efficiently, which can contribute to sustained fuel economy and consistent power delivery. For enthusiasts, a well-functioning manifold is the foundation for any further performance upgrades, as it ensures the baseline exhaust flow is not a bottleneck.

In summary, the 06180RBDE01 Exhaust Manifold is more than just a replacement part; it is a vital component engineered with professional-grade materials and precision manufacturing. It delivers the durability, fit, and performance that Honda Civic owners can depend on, making it an intelligent choice for both routine maintenance and performance-oriented projects.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |

The production of an exhaust pipe involves several precise stages, with casting and machining being fundamental for key components.

The process often begins with the casting of complex parts like the exhaust manifold or catalytic converter housing. Molten iron or stainless steel is poured into sand or die molds to create these intricate, heat-resistant shapes. Once cooled, the rough

castings undergo machining. This involves CNC milling and drilling operations to create critical sealing surfaces, mount holes,and precise interfaces for other components, ensuring perfect fit and function.

Meanwhile, the piping itself is formed from sheet metal. Steel or stainless steel coils are cut, rolled into tubes, and

seam-welded. These tubes are then cut to length and bent into specific shapes using mandrel bending machines to maintain a smooth,unrestricted airflow.

Finally, all components—cast manifolds, machined flanges, bent pipes, and silencers—are meticulously assembled by robotic and manual welding. The entire system is cleaned and often treated with high-temperature paint or coatings to enhance durability and corrosion resistance before final inspection and packaging.