- סקירה

- מוצרים מומלצים

כמפרנס מקצועי המתמחה בזריקת ברזל, אנו מספקים פתרונות מקיפים לרכיבים מברזל יצוק אפור (FC250) ומברזל גמיש (FCD500). המומחיות הייצורית שלנו משלבת ידע מסורתי בהטחת מתכות עם טכנולוגיה מודרנית, כדי לספק יציקות באיכות גבוהה המ cumpl את הדרישות התעשייתיות המגוונות מבחינת חוזק, עמידות וביצועים.

מצוינות חומר ומאפייני ביצועים

השירותים שלנו כוללים שני סוגי ברזל עיקריים עם תכונות מכניות שונות:

FC250 ברזל יצוק אפור

ברזל אפור איכותי זה מציע מאפייני יציקה מצוינים וביצועים אמינים, עם חוזק מתיחה של 250 MPa. המבנה של פליטת הגרפיט בתוכו מספק יכולת דämping טבעית של רעדים, עמידות מעולה בפני שחיקה, ו מוליכות תרמית יוצאת דופן. FC250 מציג יכולת עיבוד טובה ושומר על יציבות ממדים גםภายใตן תנאים של מחזורי חום, מה שהופך אותו לאידיאלי לשימושים הדורשים הפחתת רעש וניהול תרמי.

FCD500 ברזל גמיש

ברזל קаст סpheroidal עמיד זה מספק תכונות מכניות משופרות עם חוזק מתיחה של 500 MPa ואלונגות של 7%. המבנה הספירי של הגרפיט מספק עמידות מרשימה בפני השפעה, עמידות טובה fatigue וצמיגות משופרת בהשוואה לברזל אפור. FCD500 שומר על עמידות בפני שחת ויכולת יציקה של ברזל מסורתי, תוך כדי שהוא מספק מאפייני חוזק המתקרבים לאלו של רכיבי פלדה.

תהליך ייצור יציקה מתקדם

שיטת הייצור שלנו מבוססת על טכניקות מתקדמות של יסוד:

עיצוב ותבנית ייצור

אנו יוצרים דפוסים מדויקים באמצעות טכנולוגיית CAD/CAM, הכוללים התחשבות מתאימה בהכווצות והזנות. עיצוב הדפוס שלנו מיטיב את מערכות ההזרקה והשעיה כדי להבטיח איכות יציקה גבוהה ושחיתת חומר מינימלית.

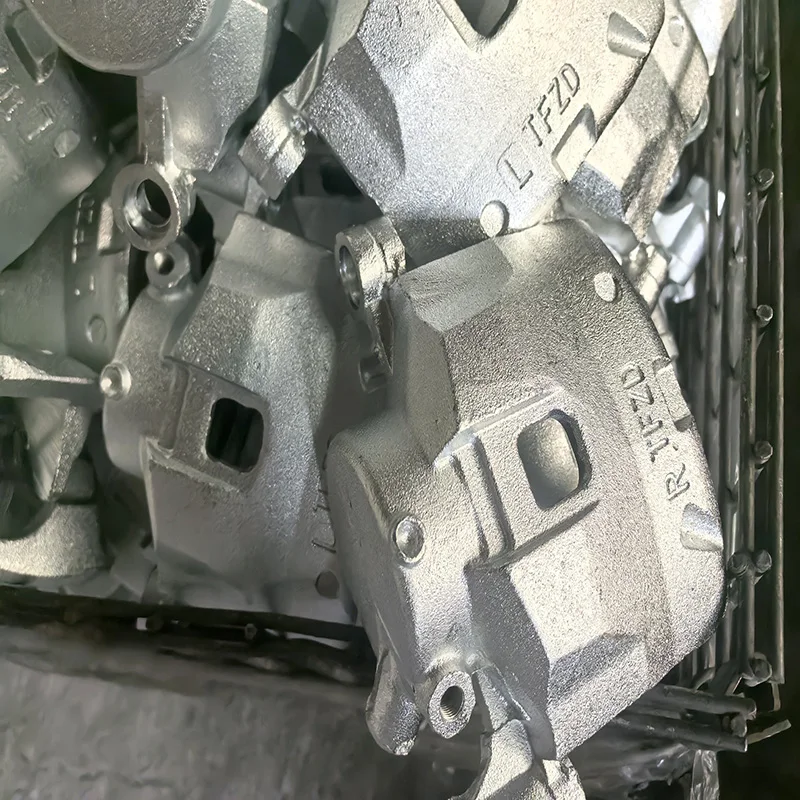

טכנולוגיהנולוגיה של ייצור

אנו משתמשים בשתי שיטות ייצור תבניות: חול ירוק וחול ריאקציה, בהתאם לדרישות הייצור:

יציקת חול ירוק לייצור בתפוקה גבוהה

מערכות חול רזינתי לגאומטריות מורכבות ולבסוף משופשף מיטבי

קווי יציקה אוטומטיים שמבטיחים עקביות באיכות

תכונות חול מבוקרות שמשמרות עוצמת תבנית אופטימלית

בקרת התכה ורִיקון

תנורי האינדוקציה שלנו בתדר בינוני שומרים על הרכב כימי וטמפרטורות יציקה מדויקות. אנו מיישמים טכניקות התזה מתקדמות הן עבור ברזל אפור והן עבור ברזל רקיע, ומבטיחים פיתוח מיקרו-מבנה ותכונות מכניות נכונות.

אבטחת איכות ואימות טכני

אנו שומרים על בקרת איכות מקיפה בכל תהליך הייצור שלנו:

ניתוח ספקטרוכימי לצורך בקרת הרכב הכימי המדויקת

בדיקת מכונות לאישור חוזק מתיחה וקשיות

בחינת מיקרו-מבנה לאישור היווצרות גרפיט

בדיקת אולטראסאונד לרכיבים קריטיים לשימוש

אימות ממדים באמצעות מכונות מדידה קואורדינטיות

יישומים ופתרונות תעשייתיים

שירותי הזרקת הברזל שלנו תומכים במספר מגזרי תעשייה:

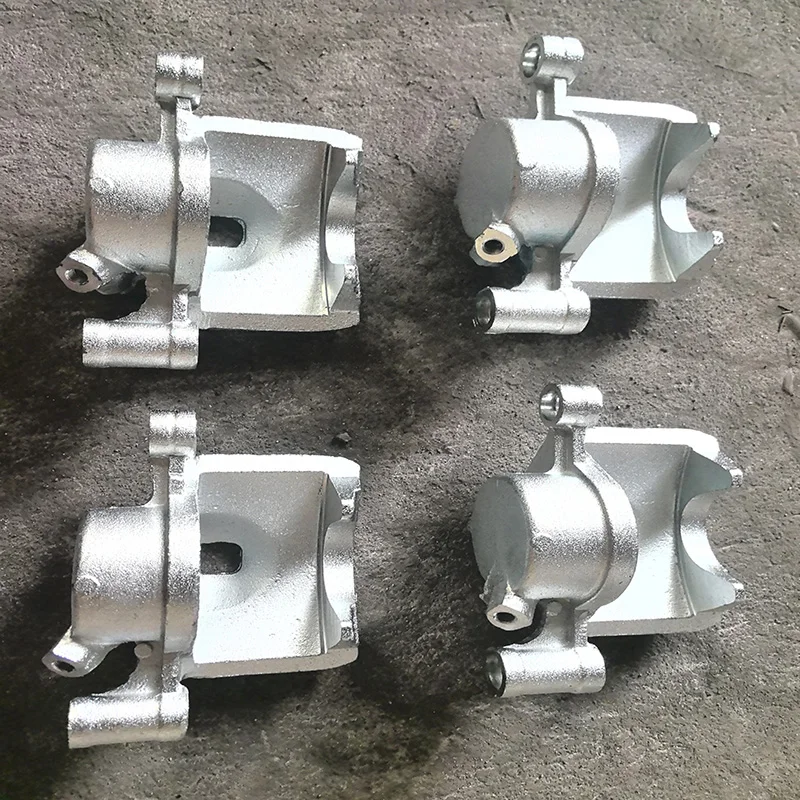

רכיבים לאוטומובילים: גלגלות מנוע, דיסקי בלימה וקופסאות הילוכים

מערכות הידראוליות: גופי משאבות, גופי שסתומים ובלוקי מאניפולד

מכונות תעשייתיות: מבני מכונות, בסיסי ציוד וחצאי גלגלים

ציוד בנייה: רכיבים עמידים ויסודיים ואלמנטים מבניים

הפקת חשמל: רכיבי טורבינה ותומכות לציוד

על ידי שילוב מומחיות בחומרים עם טכנולוגיית יציקה מתקדמת, אנו מספקים רכיבי ברזל שמאפשרים ביצועים אמינים, אורך חיים ממושך ופתרונות זולים ליישומים קשיחים. צוות ההנדסה שלנו עובד בצמוד עם הלקוחות כדי לבחור את החומר והשיטה המתאימים לייצור בהתאם לדרישות היישום הספציפיות, ומבטיח ביצועים אופטימליים וערך לכל פרויקט ייחודי.

שם המוצר |

חלקי יציקה/חלקי מתכת תבנית/חלקי יציקת חול/חלקי אלומיניום במתכת תבנית |

שירות יציקה |

זריקת מתכת, יציקת חול, יציקת כבידה, ועוד. |

חומר |

QT200, 250, HT250, אלומיניום ADC12, וכו' (לפי הדרישות שלך.) |

עיצוב כלים |

יש לנו צוות R&D משלנו שיוצר כלי עבודה בהתאמה אישית, בדרך כלל נגמר תוך 7-15 ימים. |

סטנדרטי |

תקן דיוק גבוה של סין GB. |

גימור שטח |

גימור מילון, אנדואיזציה, ציפוי אבקה, גוון עץ, החלקה, סידור, אלקטרופורזה. |

ציור |

תרשים תלת-ממדי: .step / .stp, תרשים דו-ממדי: .dxf / .dwg / .pdf |