- Overview

- Recommended Products

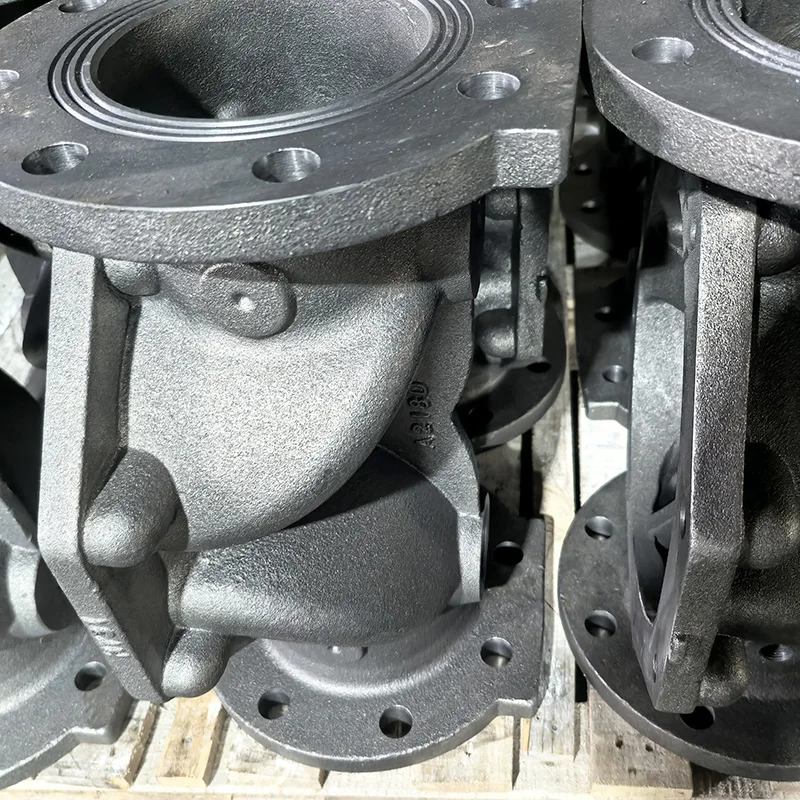

In hydraulic systems across industrial, mobile, and marine applications, cylinder housings represent critical pressure-containing components where reliability and precision are paramount. Our premium casting services specialize in manufacturing machined steel hydraulic cylinder housings that combine robust construction with exacting dimensional accuracy. Through advanced steel casting technology and precision machining capabilities, we deliver components that ensure leak-free performance, long service life, and reliable operation in the most demanding hydraulic applications.

High-Performance Steel Materials

We utilize engineered steel alloys specifically formulated for hydraulic cylinder applications:

Carbon Steel Castings: ASTM A216 WCB grade providing excellent weldability and impact resistance

Low-Alloy Steel Grades: ASTM A217 WC6/WC9 offering enhanced strength and temperature resistance

4140/4340 Alloy Steel: Superior strength-to-weight ratio with excellent fatigue properties

Stainless Steel Options: CF8/CF8M (304/316 equivalent) for corrosive environments

Custom Alloy Formulations: Tailored compositions for specific pressure, wear, or environmental requirements

All materials undergo comprehensive quality verification including spectral analysis, mechanical testing, and microstructural examination to ensure consistent performance in high-pressure hydraulic applications.

Advanced Casting and Machining Process

Our integrated production system ensures dimensional accuracy and metallurgical integrity:

-

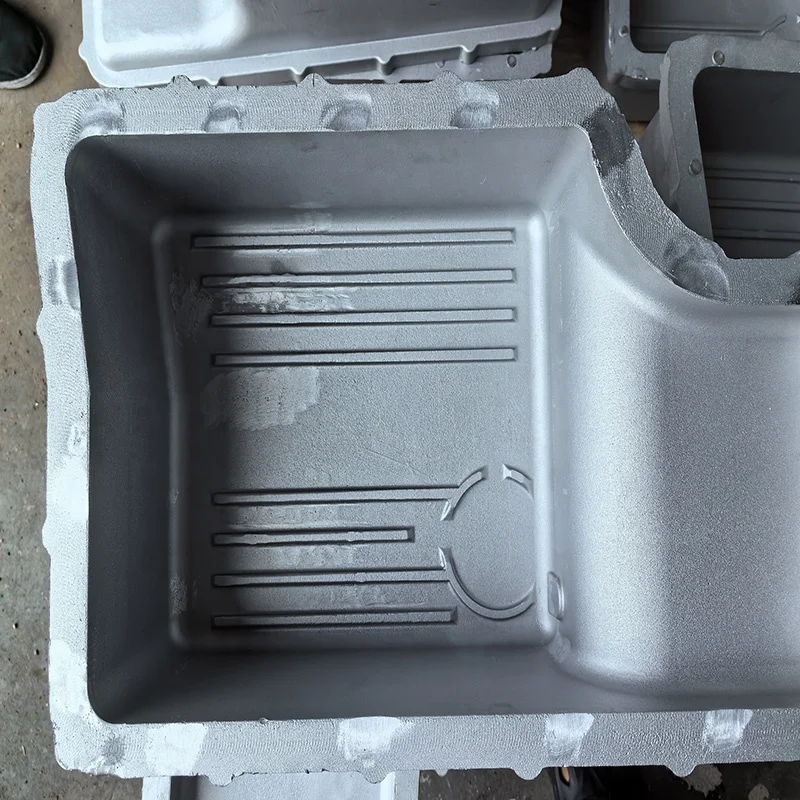

Sand Casting Technology

Resin sand molding for superior surface finish and dimensional stability

No-bake sand systems for large cylinder housing configurations

Precision core assembly for complex internal passageways

-

Casting Excellence

Controlled pouring with advanced degassing practice

Real-time thermal monitoring during solidification

Optimized gating and risering systems for sound casting structure

-

Heat Treatment Process

Normalizing and tempering for optimal mechanical properties

Stress relief annealing for dimensional stability

Quenching and tempering for high-strength applications

Through-hardening treatments for enhanced wear resistance

-

Precision Machining

CNC turning and boring of cylinder inner diameters

Precision machining of mounting interfaces and port connections

Gun drilling and honing of barrel surfaces

Threading and grooving of critical features

Surface finishing to specified roughness requirements

Performance Advantages

High Pressure Capability: Robust construction withstands working pressures up to 5,000 PSI

Superior Surface Finish: Precision-machined surfaces ensure effective seal performance

Excellent Dimensional Stability: Maintains critical tolerances under load and temperature variations

Outstanding Wear Resistance: Hardened surfaces withstand rod and piston abrasion

Reliable Sealing Surfaces: Precision-machined grooves and surfaces ensure leak-free operation

Quality Assurance Protocol

ISO 9001:2015 certified quality management system

Non-destructive testing including UT, MT, and PT

Pressure testing to 1.5 times working pressure

Dimensional verification using CMM technology

Surface roughness and profile measurement

Complete material traceability and certification

Technical Applications

Industrial hydraulic presses and machinery

Mobile equipment and construction machinery

Marine and offshore hydraulic systems

Aerospace actuation systems

Mining and agricultural equipment

Our engineering team provides comprehensive technical support from design optimization through production, ensuring perfect compatibility with your hydraulic system requirements. We maintain flexible production capabilities from prototype development to mass production, with full compliance with international pressure vessel standards. Contact our technical specialists today to discuss your hydraulic cylinder housing requirements and discover how our premium steel casting and machining services can enhance your hydraulic system performance and reliability.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |