- Overview

- Recommended Products

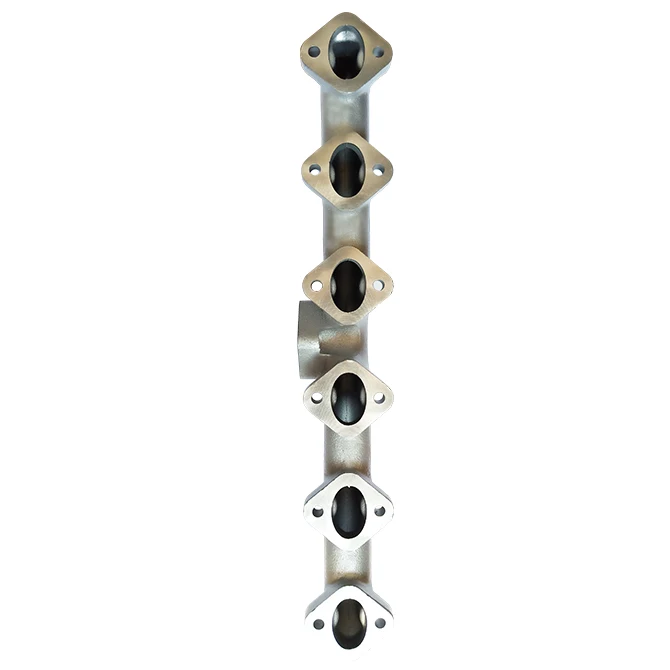

As an experienced China supplier, we provide custom casting solutions for exhaust manifolds using iron and carbon steel materials through advanced sand casting processes. Our specialized services cater to automotive, marine, and industrial applications where thermal durability, structural integrity, and cost efficiency are paramount. We combine technical expertise with competitive manufacturing to deliver components that meet international quality standards while optimizing production costs for our global clients.

Material Excellence

We offer comprehensive material options tailored to exhaust manifold requirements:

Gray Iron Castings: ASTM A48 Class 35B-40B providing excellent thermal conductivity and vibration damping characteristics

Ductile Iron Components: ASTM A536 65-45-12 offering superior strength and thermal fatigue resistance

Carbon Steel Castings: ASTM A216 WCB grade for high-temperature applications requiring enhanced mechanical properties

Heat-Resistant Alloys: Special compositions with chromium and silicon additions for extreme temperature environments

All materials undergo rigorous verification including spectral analysis, mechanical testing, and microstructural examination to ensure consistent performance under thermal cycling conditions.

Advanced Sand Casting Manufacturing

Our comprehensive production process ensures quality and precision:

-

Pattern Engineering

CNC-machined patterns with precise shrinkage allowances

3D simulation for optimized feeding and gating system design

Resin sand core production for complex internal passages

-

Molding Technology

Resin sand molding for dimensional accuracy and surface quality

Automated molding lines for production consistency

Controlled mold hardness and permeability parameters

-

Casting Process

Controlled pouring temperatures with protective atmospheres

Real-time thermal monitoring during solidification

Optimized risering design for sound casting structure

-

Post-Casting Operations

Stress relief heat treatment for dimensional stability

CNC machining of flanges and mounting surfaces

Hot isostatic pressing (HIP) for critical applications

Surface treatment and coating applications

Performance Advantages

Superior Thermal Fatigue Resistance: Withstands repeated heating and cooling cycles without cracking

Excellent High-Temperature Strength: Maintains structural integrity under continuous thermal stress

Optimized Exhaust Flow: Smooth cast surfaces and precise runner geometry minimize flow restriction

Cost-Effective Production: Competitive pricing without compromising quality standards

Reliable Durability: Proven performance in demanding automotive and industrial applications

Quality Assurance

ISO 9001:2015 certified quality management system

Dimensional inspection using CMM technology

Pressure testing and leak detection capabilities

Non-destructive testing including radiographic examination

Complete material certification and traceability

Industry Applications

Automotive and commercial vehicle engines

Marine and industrial power systems

Agricultural and construction equipment

Generator sets and stationary engines

Performance and racing applications

Our technical team provides comprehensive support from design optimization through production, ensuring optimal performance for your specific exhaust manifold requirements. We maintain strict quality control throughout our manufacturing process and deliver components that meet international specifications. Contact our engineering specialists today to discuss your custom exhaust manifold needs and benefit from our competitive China sourcing advantages combined with technical expertise in sand casting technology.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |