High Precision CNC Machining for Aluminium Shell Precision Casting Services for Auto & Machinery Parts

- Overview

- Recommended Products

In today's advanced manufacturing landscape, high precision CNC machining and precision casting services for aluminum components have become indispensable for producing reliable, efficient auto and machinery parts. These integrated manufacturing processes combine exceptional accuracy with material excellence to meet the demanding requirements of modern industrial applications.

Advanced Aluminum Material Properties

Aluminum alloys stand as the premier material for auto and machinery components due to their exceptional strength-to-weight ratio and superior thermal conductivity. These characteristics make aluminum ideal for applications where weight reduction is critical without compromising structural integrity. The material's natural corrosion resistance ensures longevity even in challenging operating environments, while its excellent machinability allows for high production rates and superior surface finishes.

Specific aluminum alloys including A356, 6061, and 7075 offer varying combinations of castability, mechanical strength, and environmental resistance, allowing manufacturers to select the optimal material based on application requirements. The plasticity of aluminum is particularly advantageous in CNC machining, as it facilitates better stress distribution during cutting operations, reduces tool wear, and enables more complex geometrical features without compromising material integrity.

Precision Manufacturing Capabilities

CNC Machining Excellence

Modern multi-axis CNC machining centers deliver unparalleled precision for aluminum components, with capabilities including 5-axis simultaneous machining for complex contours and tight tolerance maintenance within ±0.005mm. Advanced CNC systems incorporate high-speed spindles reaching 24,000 rpm, enabling exceptional surface finishes while maintaining dimensional accuracy across production batches.

The integration of automated tool-changing systems and pallet changers ensures continuous operation for mass production requirements. For large components such as automotive structural elements, specialized solutions like double five-axis head machining centers can dramatically improve efficiency, potentially reducing processing time by over 50% compared to conventional equipment.

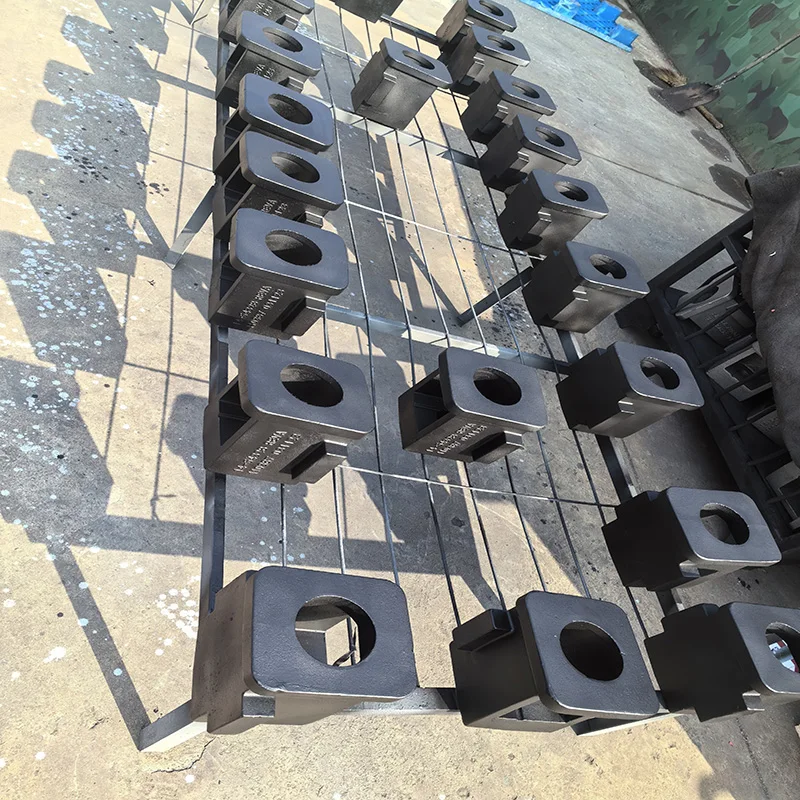

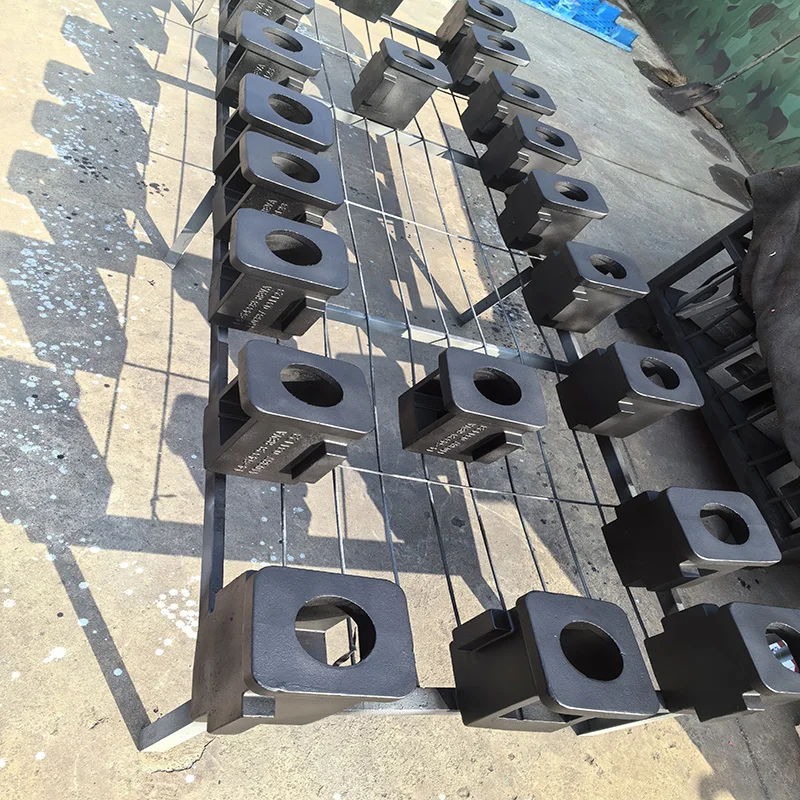

Precision Casting Processes

Complementing CNC machining, precision casting methods including vacuum high-pressure casting produce near-net-shape aluminum components with minimal porosity. Modern casting systems incorporate 4,000T large aluminum die-casting islands that integrate with CNC precision machining centers to form closed-loop production lines, enabling seamless transition from molten aluminum to finished components.

These advanced casting techniques incorporate vacuum-assisted systems to minimize air entrapment, resulting in denser castings with enhanced mechanical properties. The precision achieved through these methods allows for weight误差控制 within ±50 grams for large structural components, representing a threefold improvement in precision over traditional processes.

Enhanced Performance Characteristics

Components manufactured through these integrated processes deliver:

Exceptional dimensional stability across temperature variations and mechanical loads

Superior mechanical properties with tensile strengths reaching 45-83 ksi depending on alloy selection and heat treatment

Enhanced surface integrity with finishes achieving Ra 0.2-0.8 μm through optimized machining parameters

Excellent thermal management leveraging aluminum's natural conductivity for heat dissipation

Long-term reliability with minimal maintenance requirements in demanding applications

Comprehensive Application Range

Automotive Industry

The automotive sector extensively utilizes precision-machined aluminum components for both traditional and emerging applications:

Structural Elements: Battery trays, sub-frames, and cross-members produced through integrated die-casting and CNC machining

Powertrain Components: Engine brackets, transmission cases, and mounting elements requiring high strength-to-weight ratios

Electric Vehicle Systems: Battery enclosure components, motor housings, and power distribution elements

Machinery and Industrial Equipment

Precision aluminum components serve critical functions across industrial sectors:

Automation Systems: Robotic end effectors, guidance components, and machinery frames

Fluid Handling Systems: Pump housings, valve bodies, and compressor parts

Processing Equipment: Machinery bases, structural supports, and equipment enclosures

Quality Assurance and Technical Excellence

Leading manufacturers implement rigorous quality management systems incorporating:

First-article inspection using coordinate measuring machines (CMM) with precision up to 0.015mm

Statistical process control monitoring key parameters throughout production cycles

Material certification verifying composition and mechanical properties to international standards

Non-destructive testing including

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |