- Overview

- Recommended Products

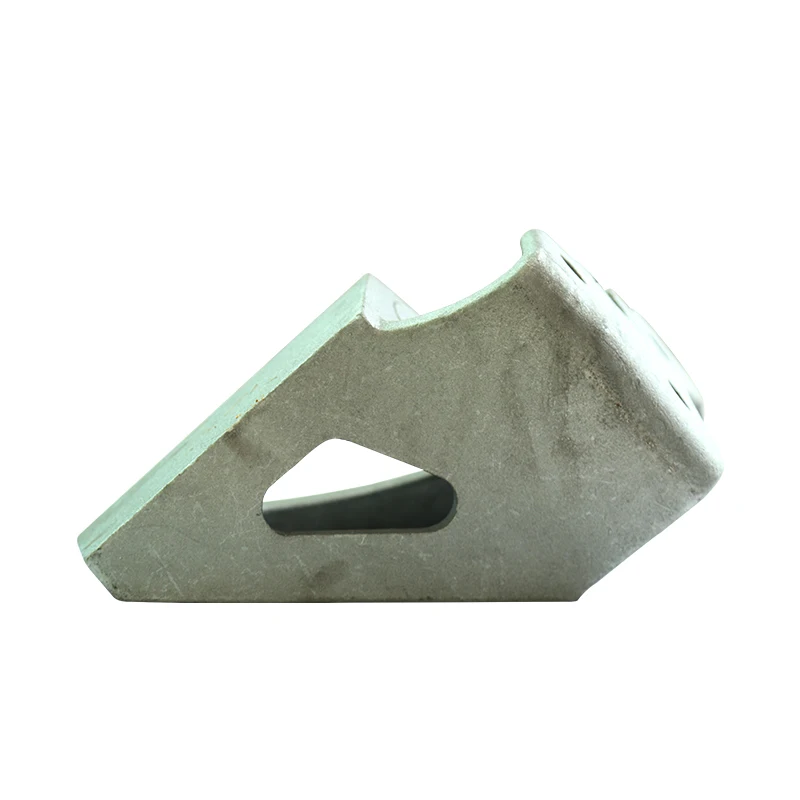

In industries where structural integrity, complex geometry, and reliability are paramount, Customized Precision Steel Investment Casting Bracket Parts deliver an unparalleled solution. This advanced manufacturing process enables the production of high-strength, intricate bracket components with exceptional dimensional accuracy and superior surface finish, tailored to meet the rigorous demands of aerospace, automotive, and heavy machinery applications.

Premium Material Selection for Demanding Environments

We utilize high-performance steel alloys including 4140, 4340, and 17-4PH stainless steel, selected for their exceptional mechanical properties and versatility. These materials offer:

High tensile strength (up to 1400 MPa) and yield strength

Excellent impact and fatigue resistance

Superior corrosion resistance in harsh environments

Good machinability and heat treatment response

The specific alloy is chosen based on application requirements, whether for weight-critical aerospace components or wear-resistant industrial brackets, ensuring optimal performance under stress, vibration, and temperature variations.

Advanced Investment Casting Process for Complex Geometries

Our manufacturing employs the sophisticated investment casting process, beginning with rapid prototyping of precise wax patterns using advanced tooling. Multiple patterns are assembled into clusters and repeatedly dipped in ceramic slurry to build a robust mold shell. After dewaxing and high-temperature firing, the resulting mold is poured with molten steel under controlled atmospheric conditions. This process enables:

Production of complex shapes with internal passages and thin walls

Tight tolerances within ±0.005 inches per inch

Superior surface finishes ranging from 125 to 250 Ra

Minimal material waste and reduced secondary machining requirements

Precision Engineering and Quality Assurance

Each casting undergoes rigorous post-processing including:

Heat treatment (quenching and tempering) for enhanced mechanical properties

Precision CNC machining on critical interfaces and mounting surfaces

Non-destructive testing (X-ray and dye penetrant inspection)

Dimensional verification using CMM equipment

This comprehensive approach ensures every bracket meets exact specifications for flatness, hole positioning, and thread accuracy.

Diverse Industrial Applications

Our custom steel investment casting brackets serve critical functions across multiple sectors:

Aerospace: Engine mounts, structural supports, and actuator brackets

Automotive: Suspension components, transmission brackets, and safety system mounts

Industrial: Heavy machinery frames, robotic arm attachments, and hydraulic system supports

Defense: Weapon system mounts and vehicle structural components

By combining advanced metallurgy with precision manufacturing, we deliver bracket parts that outperform conventional fabricated alternatives in strength-to-weight ratio, design flexibility, and overall reliability. Our technical team collaborates closely with clients from design optimization through production, ensuring each customized bracket solution meets exact performance requirements while reducing total production costs through minimized machining and assembly operations.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |