- Overview

- Recommended Products

In the pursuit of automotive lightweighting and performance optimization, magnesium alloy has emerged as a strategic material for advanced components. Our integrated service combines magnesium die casting with precision CNC lathe and CNC machining capabilities to deliver customized solutions tailored for the automotive industry. This synergistic approach enables the production of complex, high-strength, and ultra-lightweight parts that meet the stringent requirements of modern vehicle systems.

Advanced Material: Magnesium Alloy

Magnesium alloys (such as AZ91D and AM60B) offer exceptional properties for automotive applications:

Ultra-Lightweight: With a density of 1.8 g/cm³, magnesium is 30% lighter than aluminum and 75% lighter than steel, significantly reducing vehicle weight for improved fuel efficiency and emissions reduction.

High Strength-to-Weight Ratio: Provides excellent structural integrity while minimizing mass.

Good Damping Capacity: Effectively absorbs vibrations and noise, enhancing ride comfort.

Excellent Castability: Enables production of thin-walled components with complex geometries.

Integrated Manufacturing Process

Our comprehensive manufacturing approach ensures superior quality:

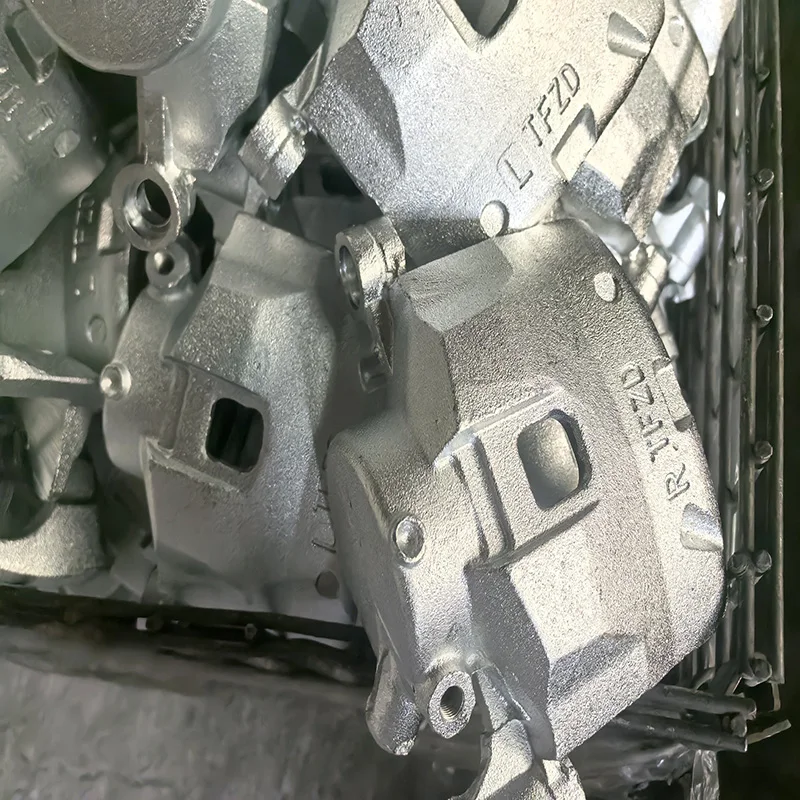

High-Pressure Die Casting: Molten magnesium is injected into precision molds under controlled atmosphere to prevent oxidation, producing near-net-shape components with excellent dimensional stability.

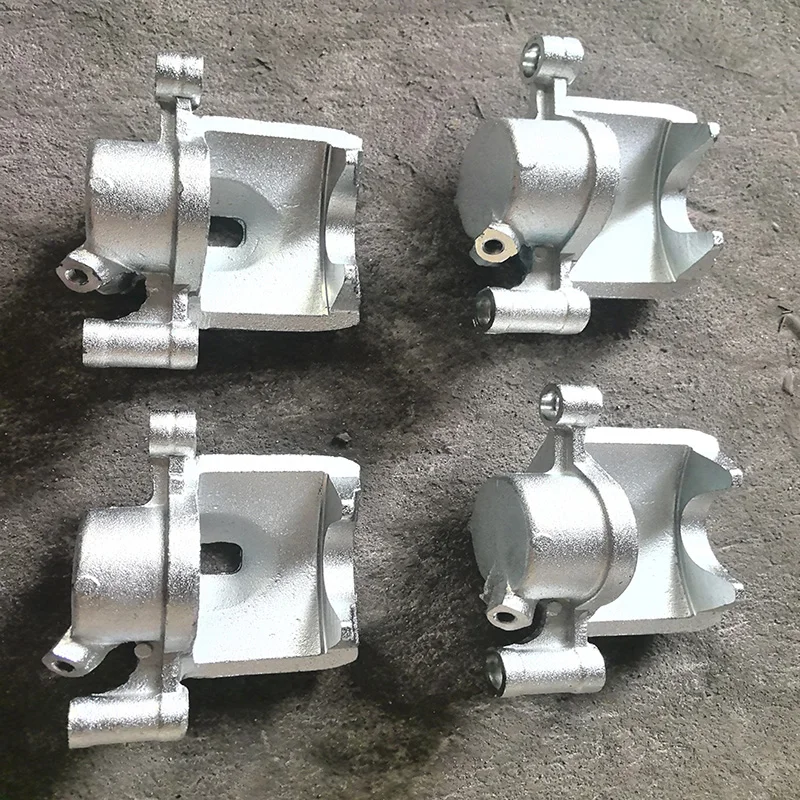

CNC Machining: Advanced CNC lathes and machining centers perform precision turning, milling, and drilling operations to achieve tight tolerances (±0.02mm) and perfect surface finishes.

Heat Treatment: Solution treatment and aging processes enhance mechanical properties and dimensional stability.

Surface Treatment: Specialized coatings and anodizing processes provide corrosion protection and improved wear resistance.

Performance Advantages

Weight Reduction: Up to 30% lighter than equivalent aluminum components

Complex Geometries: Capable of producing intricate designs with thin walls (1.0-1.5mm)

High Temperature Resistance: Maintains structural integrity up to 120°C

Excellent EMI Shielding: Natural electromagnetic interference protection

Automotive Applications

Powertrain Components: Transmission cases, oil pump housings

Interior Systems: Steering column brackets, seat frames

Body and Chassis: Instrument panel supports, bracket assemblies

Electrification Components: Battery enclosure parts, motor housings

Our customized magnesium die casting and CNC machining services provide automotive manufacturers with lightweight solutions that don't compromise on strength or precision. Contact us today to discuss how our magnesium components can enhance your automotive applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |