- Overview

- Recommended Products

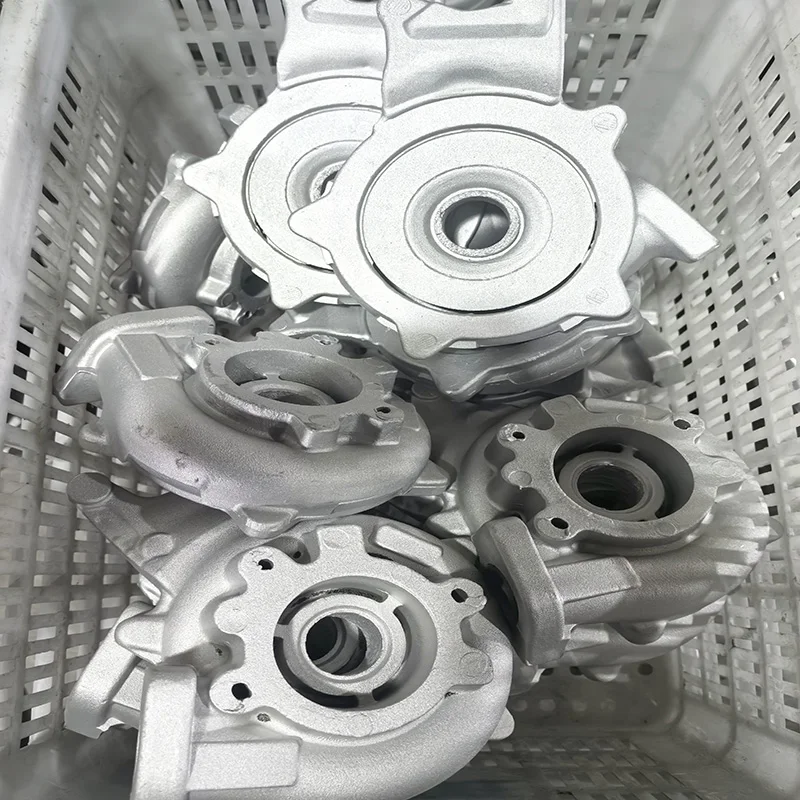

In the automotive industry, the reliability of engine cooling systems hinges on the performance of critical components like the Water Pipe Outlet. Our Customized Auto Parts Gravity Aluminum Casting Services specialize in producing these essential parts by leveraging advanced gravity casting techniques. This process ensures superior metallurgical integrity, dimensional accuracy, and cost-effectiveness, making it the ideal manufacturing solution for high-volume automotive applications.

Advanced Aluminum Alloys for Demanding Environments

We utilize high-strength aluminum alloys, such as A356.0 and Al-Si series materials, selected for their exceptional balance of properties. These alloys deliver:

Excellent Castability: Ensures complete filling of complex molds and thin-walled sections -1.

High Strength-to-Weight Ratio: Critical for reducing overall vehicle weight while maintaining structural integrity -8.

Superior Corrosion Resistance: Withstands prolonged exposure to coolants and environmental contaminants -9.

Enhanced Thermal Conductivity: Promotes efficient heat dissipation from the engine -8.

Post-casting T6 heat treatment further elevates tensile strength and pressure tightness, enabling the water pipe outlets to withstand operating pressures exceeding 50 kg/cm² -8.

Precision Gravity Casting Process

Our manufacturing approach combines rigorous design analysis with proven gravity casting methods:

Metal Mold Design: Reusable molds (e.g., from H-13 steel) ensure consistent dimensional stability and rapid cooling for a dense microstructure -3-8.

Optimized Pouring Systems: Employing gravity top-pouring or open gating (e.g., 1:4:5 ratio) to minimize turbulence and gas entrapment -2-4.

Defect Control: Strategic use of chills and vents prevents porosity and cold shuts, which is crucial for leak-free performance -6-10.

CNC Machining: Secondary machining guarantees precise mating surfaces and connector threads for perfect assembly integration.

Key Performance Advantages

Leak-Free Integrity: Pressure tightness validated to automotive standards.

Cost-Efficiency: Lower tooling costs compared to alternatives like low-pressure casting -5-7.

Design Flexibility: Accommodates complex geometries with integrated mounting bosses and coolant passages.

Durability: Resists cavitation erosion and thermal cycling fatigue.

Quality Assurance

Every unit undergoes rigorous checks, including:

X-ray Inspection: Detects internal defects per ASTM standards -4.

Dimensional Verification: CMM-based alignment checks.

Pressure Testing: Hydrostatic tests at 1.5x operating pressure.

Applications in Automotive Systems

Our gravity-cast water pipe outlets are integral to:

Engine Cooling Modules: Connecting radiators, thermostats, and pumps.

Hybrid Vehicle Thermal Management: Battery and power electronics cooling.

Exhaust Gas Recirculation (EGR) Systems: Coolant circulation components.

By integrating Customized Gravity Aluminum Casting Services, we deliver water pipe outlets that optimize thermal management, reduce vehicle weight, and enhance engine reliability. Our technical collaboration ensures components meet precise OEM specifications, supporting global automotive innovation and sustainability goals.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |