- Overview

- Recommended Products

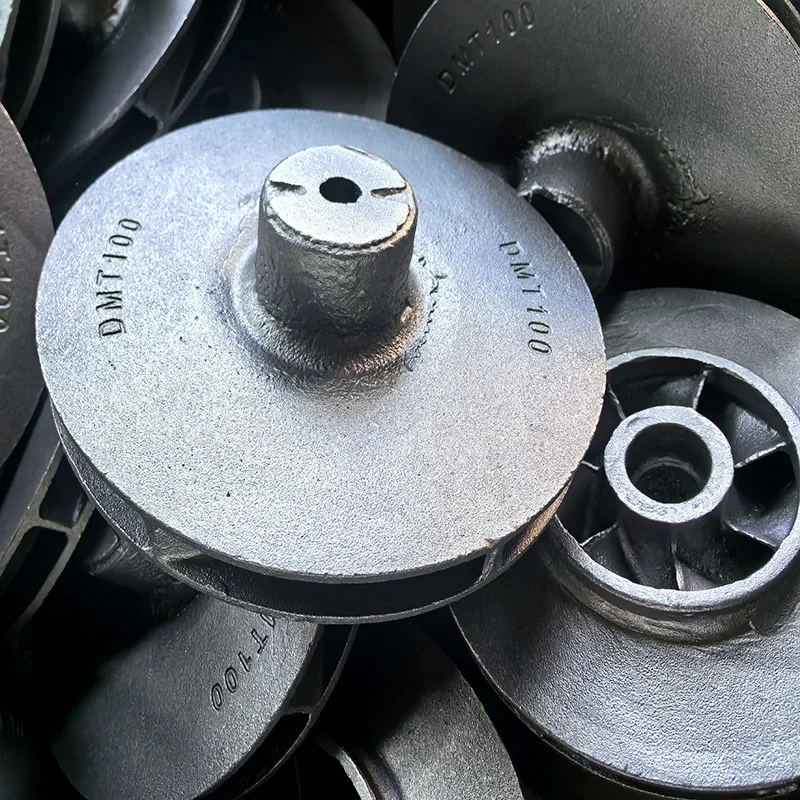

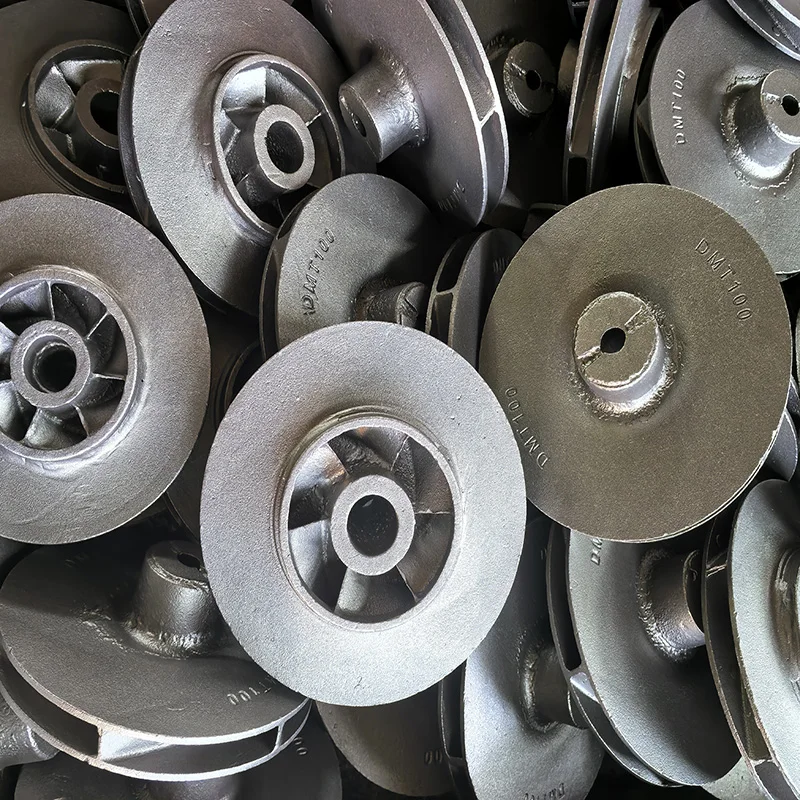

Precision Engineering for Demanding Applications

Our custom stainless steel block sand form casting machining services deliver exceptional quality components for industrial applications requiring superior corrosion resistance and mechanical strength. We specialize in producing complex stainless steel blocks through advanced sand casting techniques combined with precision machining capabilities, ensuring complete customer satisfaction from prototype to production run.

Advanced Material Selection

We work with a comprehensive range of stainless steel grades to meet specific application requirements:

304/L stainless steel for excellent general corrosion resistance

316/L stainless steel for enhanced resistance to chlorides and acids

410/420 stainless steel for applications requiring high strength and wear resistance

Duplex stainless steels for superior stress corrosion cracking resistance

Each material undergoes rigorous certification and testing to guarantee chemical composition and mechanical properties meet international standards.

Superior Performance Characteristics

Our stainless steel casting services produce components with outstanding properties:

Corrosion resistance in various environments including chemical, marine, and high-temperature applications

High tensile strength ranging from 70-120 ksi depending on grade and heat treatment

Excellent impact toughness at both elevated and sub-zero temperatures

Good machinability and weldability for secondary processing

Pressure tightness up to 1000 PSI for critical fluid handling applications

Comprehensive Manufacturing Process

Our integrated manufacturing approach ensures highest quality:

Sand Casting Process:

Utilization of resin-bonded sand molds for superior dimensional accuracy

CAD/CAM pattern design for complex geometries and tight tolerances

Controlled pouring temperatures and solidification rates

Advanced gating and risering systems to minimize shrinkage defects

Machining Operations:

CNC milling and turning with precision tolerances (±0.001")

Deep hole drilling and boring capabilities

Surface grinding and finishing services

Comprehensive quality control with CMM verification

Quality Assurance and Testing

Every component undergoes rigorous inspection:

Liquid penetrant testing for surface defect detection

Radiographic examination for internal quality verification

Mechanical testing including tensile and impact tests

Chemical analysis and material certification

Dimensional inspection per customer specifications

Industry Applications

Our services support multiple sectors:

Valve bodies and pump casings for oil and gas industry

Food processing equipment components

Marine hardware and shipbuilding components

Chemical processing equipment

Architectural and structural applications

Technical Capabilities

Maximum casting weight: 5000 lbs

Dimensional tolerance: ±0.015" for first inch

Surface finish: 125-250 Ra as-cast, 32-125 Ra machined

Lead time: 4-6 weeks for standard projects

Prototype development available

By combining traditional sand casting expertise with modern machining technology, we deliver stainless steel components that exceed industry standards while providing cost-effective solutions for demanding applications. Our engineering team works closely with clients to optimize designs for manufacturability and performance, ensuring optimal value throughout the product lifecycle.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |