- نظرة عامة

- المنتجات الموصى بها

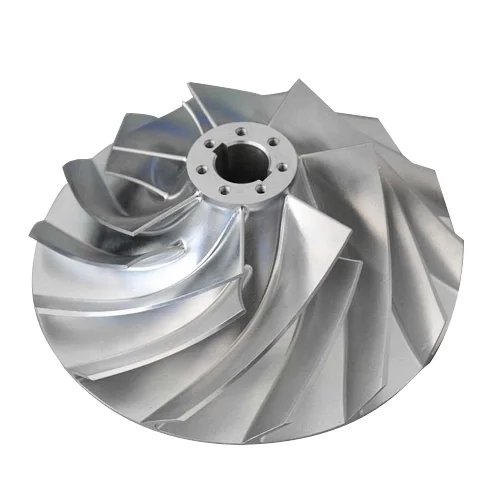

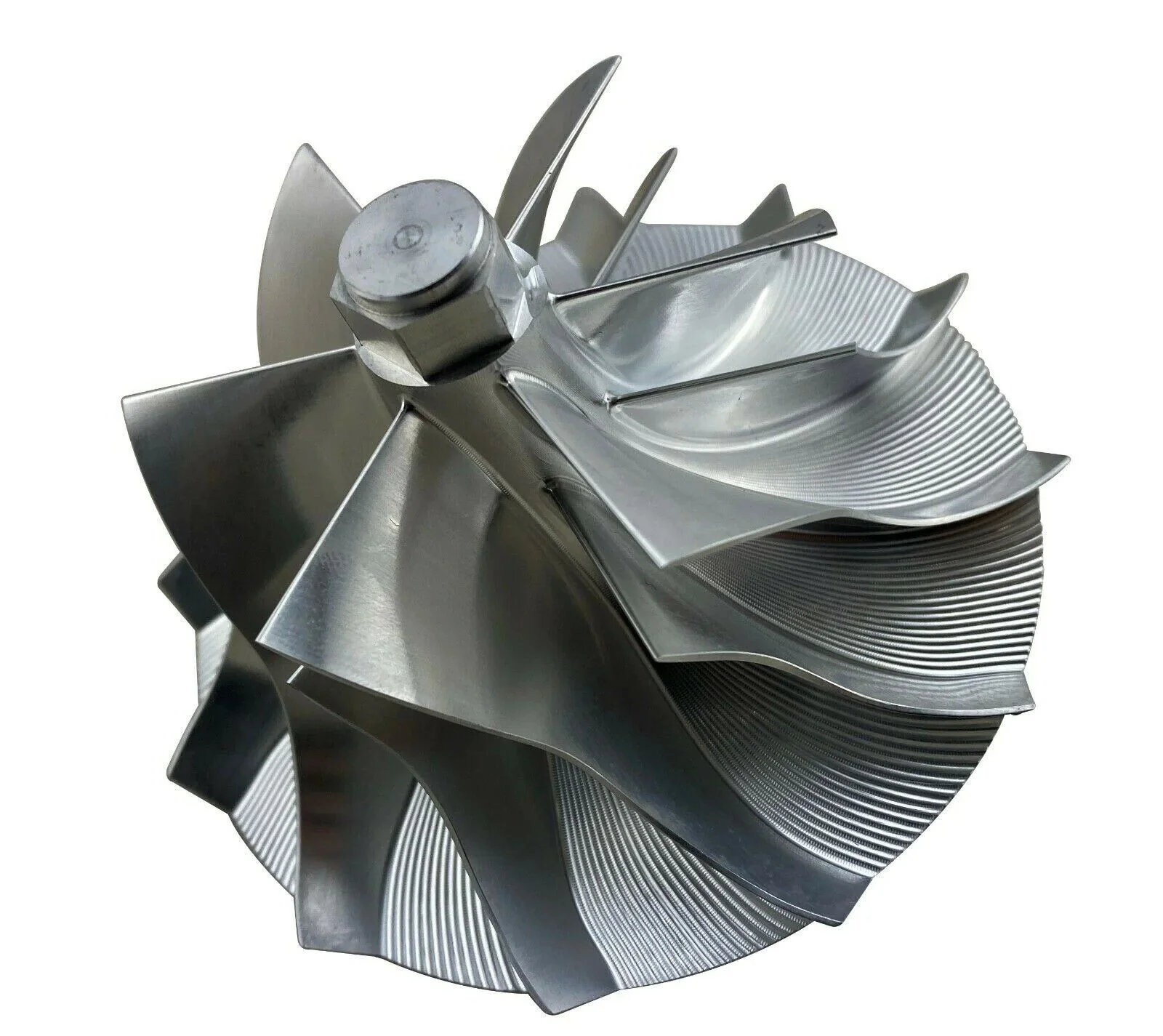

في عالم التقوية القسري عالي المخاطر، تمثل عجلة الضاغط القلب النابض لشاحن التربو، حيث تحدد استجابته وكفاءته والإنتاج النهائي للقوة. إن عجلة ضاغط الشاحن التربيني المصنعة بدقة، وهي منتج لخدمات صب متقدمة، تمثل القمة في الهندسة الهوائية والميكانيكية. تم تصميم هذا المكون الحيوي للمهتمين بالأداء، وللمصنعين الأصليين (OEM)، ولصناعة قطع الغيار بعد البيع الذين يبحثون عن موثوقية استثنائية وزيادة في القوة.

علم المواد المتقدم للبيئات القاسية

تبدأ سلامة عجلة الضاغط من مادتها. نستخدم سبائك ألومنيوم عالية القوة ومقاومة للحرارة، مثل 2618 أو 4032، مختارة خصيصًا لخصائصها الاستثنائية. توفر هذه السبائك مزيجًا مثاليًا من الكثافة المنخفضة لسرعة لفّ اللفة ومقاومة عالية للخضوع لتحمل قوى الطرد المركزي الهائلة ودرجات الحرارة المرتفعة عند سرعات دوران عالية (غالبًا ما تتجاوز 150,000 دورة في الدقيقة). هذا يضمن ثباتًا بُعديًا طويل الأمد ومقاومة للتعب، وهو أمر بالغ الأهمية للأداء والسلامة.

الكفاءة والأداء المتميزان هوائيًا

كل عجلة هي تحفة من حيث الكفاءة الهوائية. وتشمل الخصائص الرئيسية للأداء ما يلي:

هندسة الشفرات المُحسّنة: تم تصميم ملفات الخرج والدخل بدقة بهدف تعظيم ضغط الهواء وتدفقه، وتقليل الاضطرابات لتحقيق كفاءة أدياباتية أعلى.

التلف السريع: يقلل التصميم الخفيف الوزن ، جنبا إلى جنب مع زوايا الشفرة الدقيقة ، من ثابته الدورانية ، مما يؤدي إلى استجابة أسرع للضغط وتخفيض تأخر التوربو.

قدرة التدفق العالية: مصممة لنقل كتلة أكبر من الهواء ، ودعم زيادات كبيرة في القوة والقلبين لكل من تطبيقات البنزين والديزل.

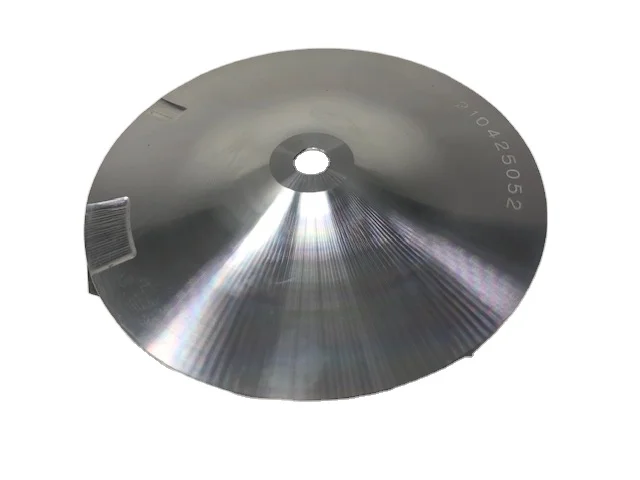

عملية التصنيع الدقيق والصب

عجلاتنا ليست مجرد صب؛ أنها هندسية. تبدأ عملية التصنيع بتقنية صب الاستثمار من الشمع المفقود، والتي تخلق مكونًا شبه صافي الشكل مع نهاية سطحية رائعة وهيكل الحبوب. ثم يخضع هذا "الشرط" لعملية معالجة دقيقة من قبل CNC. تستخدم آلات CNC ذات 5 محاور متطورة لإنهاء الشفرات والحبل والحفر إلى معايير التسامح المجهرية. يضمن ذلك التوازن المثالي ، والتركيز الحقيقي ، والتكيف المثالي مع عمود التوربين ، وهو أمر بالغ الأهمية للعمل السلس ، عالية RPM والموثوقية على المدى الطويل.

مجموعة واسعة من التطبيقات

هذه العجلة المضغوطة ذات الآلات الدقيقة هي مكون أساسي لـ:

إعادة بناء شاحن توربيني أداء عالي: ترقية مباشرة للعجلات التالفة أو القديمة من المصنع في الشواحن التوربينية من جاريت، بورج وارنر، هانيويل، وآخرين.

ترقيات الشواحن التوربينية بعد البيع: العنصر المركزي في تركيبات الشواحن التوربينية الهجينة للسيارات والشاحنات والتطبيقات البحرية.

الاستخدامات الثقيلة والسباقات: ضرورية لتطبيقات الأداء الديزل والسباقات التنافسية حيث تكون الموثوقية والحد الأقصى للقوة أمراً لا غنى عنه.

استثمر في عجلة الضاغط التي توفر أداءً مثبتًا من الداخل إلى الخارج. تضمن خدمات الصب والتشغيل الدقيق لدينا منتجًا يلبي أعلى معايير الجودة وأداء القوة.

المادة |

الفولاذ، الفولاذ المقاوم للصدأ، الألومنيوم، الحديد، الفولاذ الكربوني، النحاس، البرونز، السبائك، إلخ. |

السُمك |

0.1 مم إلى 12 مم، حسب طلبك |

الأحجام |

1) وفقًا لرسومات العملاء 2) وفقًا لعينات العملاء |

المعالجة السطحية |

الأنودة، الجلفنة، الزنك، النيكل، الكروم، الطلاء المسحوق، الطلاء، إلخ. |

صيغة الرسم |

DWG، DXF، STEP، STP، STL، AI، PDF، JPG، الرسم. |

التغليف |

كيس بلاستيكي + صندوق كرتون + علبة خشبية / حملة، وفقًا لطلب العميل |

شحنة |

1) عن طريق البريد السريع، مثل DHL، TNT، Fedex، إلخ، عادةً يصل في غضون 5-7 أيام |

2) عن طريق الجو إلى مطار، عادةً يصل في غضون 3-4 أيام |

|

3) عن طريق الميناء البحري، عادةً يستغرق 15-30 يومًا للوصول |

|

وقت التسليم |

يعتمد على الكميات، عادةً حوالي 20 يومًا. |

شروط الدفع |

ت/ت، باي بال، ضمان التجارة |

الشهادة |

إيزو |

خدمة الشعار |

وفَّر |

التطبيق |

مستخدم بشكل واسع في البناء، الصناعة، صناعة السيارات. |