- نظرة عامة

- المنتجات الموصى بها

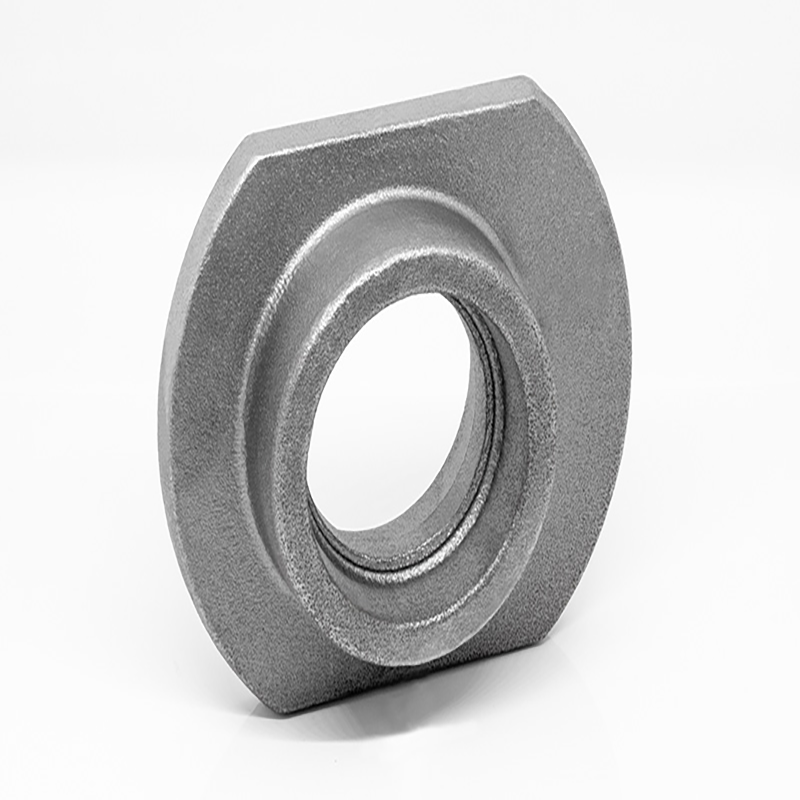

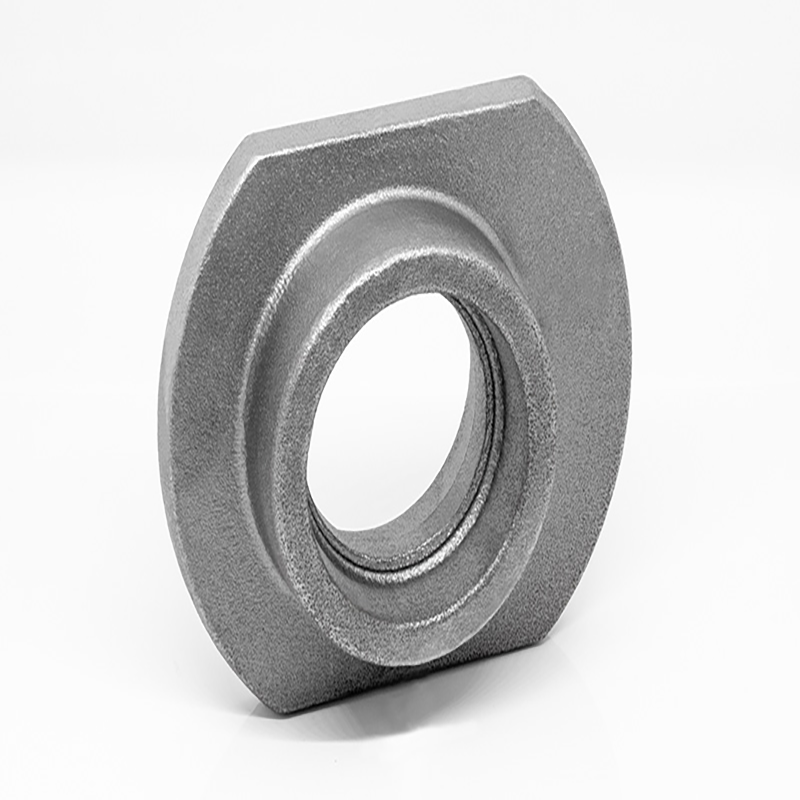

تُقدّم شركة بنغشين، مصنع خدمات التصنيع حسب الطلب للسحب والتشكيل باستخدام الضرب الساخن للأجزاء الفولاذية.

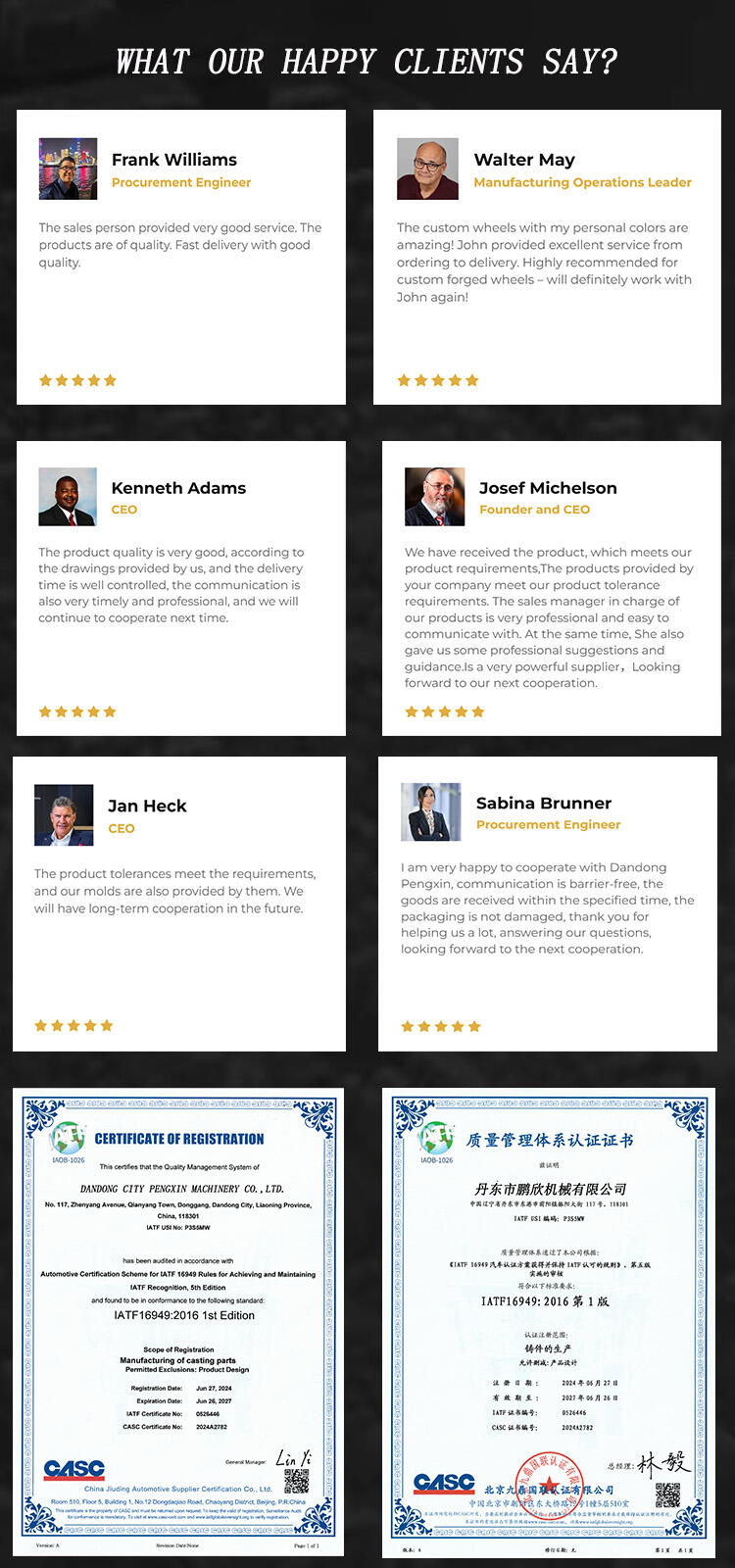

إن شركة بنغشين تُعتبر من الأسماء الموثوقة في هذا المجال، حيث تُزوّد خدمات تصنيع وسحب الأجزاء الفولاذية ذات الجودة العالية. مصنعنا مجهز بأحدث المعدات وفريق من المهنيين المهرة، ملتزمين بتقديم منتجات استثنائية تلبي أعلى معايير الجودة والأداء.

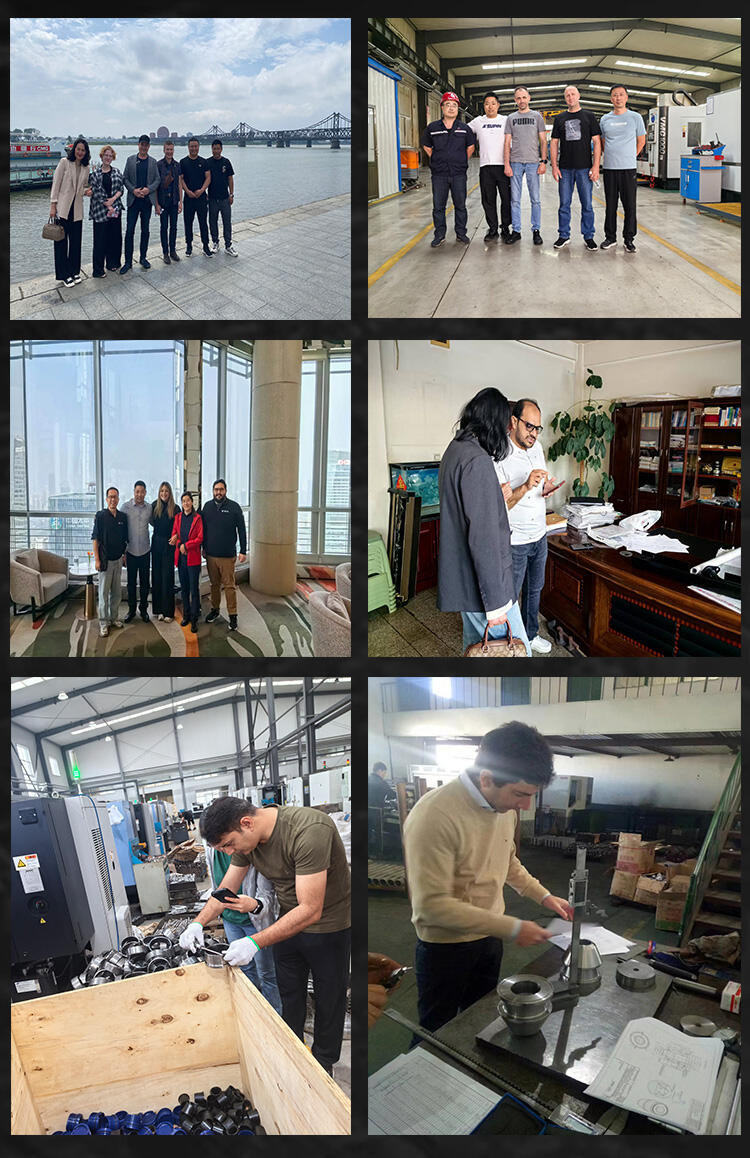

عندما يتعلق الأمر بخدمات تصنيع التزوير المخصصة، فإن شركة بنغ شين لا تُضاهى. نحن نعمل عن كثب مع عملائنا لفهم احتياجاتهم ومتطلباتهم المحددة، وضمان أن كل منتج ننتجه مصمم خصيصًا وفقًا لمواصفاتهم الدقيقة. من الفكرة إلى الإكمال، يلتزم فريقنا بتوفير عملية سلسة وفعالة تحقق نتائج متميزة في كل مرة.

في شركة بنغ شين، نؤمن بأن الجودة لها الأولوية. ولهذا السبب نستخدم فقط أفضل المواد وأحدث التقنيات لإنتاج أجزاء التزوير الساخن من الصلب. يقوم فريقنا المكون من مهندسين وفنيين متخصصين بإجراء فحوصات صارمة للتحكم في الجودة على كل مراحل عملية الإنتاج، وذلك لضمان مطابقة كل منتج لمعاييرنا الصارمة للتميز.

سواء كنت بحاجة إلى دفعة صغيرة من أجزاء الصب المطروقة حسب الطلب أو إنتاج واسع النطاق، فإن شركة بينغشين تمتلك القدرة والخبرة للتعامل مع أي مشروع، كبيرًا كان أم صغيرًا. إن مصنعنا مجهز تجهيزًا كاملاً للتعامل مع مجموعة واسعة من خدمات تصنيع التزوير، بدءًا من التزوير والمعالجة الحرارية وحتى التشغيل والتشطيب. بغض النظر عن تعقيد المشروع، فإن لدينا الأدوات والمعارف اللازمة لتقديم نتائج استثنائية تفوق توقعاتك.

عندما تختار بينغشين لتلبية احتياجاتك من تصنيع القطع المطروقة حسب الطلب، يمكنك أن تطمئن إلى أنك تحصل على أفضل المنتجات المتاحة في السوق. إن التزامنا بالجودة والدقة ورضا العملاء هو ما يميزنا عن المنافسين، مما يجعلنا الخيار الأول للعملاء في جميع أنحاء العالم.

اكتشف الفرق الذي يمكن أن تحدثه خدمات تشكيل وتصنيع قطع السباكة المخصصة لمصنع بينغكسين لعملك. تواصل معنا اليوم لمعرفة المزيد حول خدماتنا وكيف يمكننا مساعدتك في مشروعك التالي. اعتمد على بينغكسين لجميع احتياجاتك من قطع الصب الساخن للصلب

المادة |

الألومنيوم، الحديد الزهر الرمادي، الحديد الدكتايل، الفولاذ المقاوم للصدأ، النحاس، البرونز، المجلفن إلخ |

||||||

الحجم |

مخصص |

||||||

المعالجة السطحية |

الطلاء الكهروستاتيكي والطلاء الكهربائي والأكسدة والأنودة |

||||||

تقنيات |

القطع بالليزر، والثني، واللحام، والختم، والصهر، والتشكيل |

||||||

الشهادة |

الـ ISO9001:2015 |

||||||

OEM |

قبول |

||||||

صيغة الرسم |

3D/CAD/Dwg/IGS/STEP |

||||||

اللون |

مخصص |

||||||

التطبيق |

الأجهزة المنزلية، السيارات، البناء، المعدات الرأسمالية، الطاقة، الأدوات، الأجهزة الطبية، الاتصالات |

||||||

من نحن

ما قبل البيع

أثناء البيع

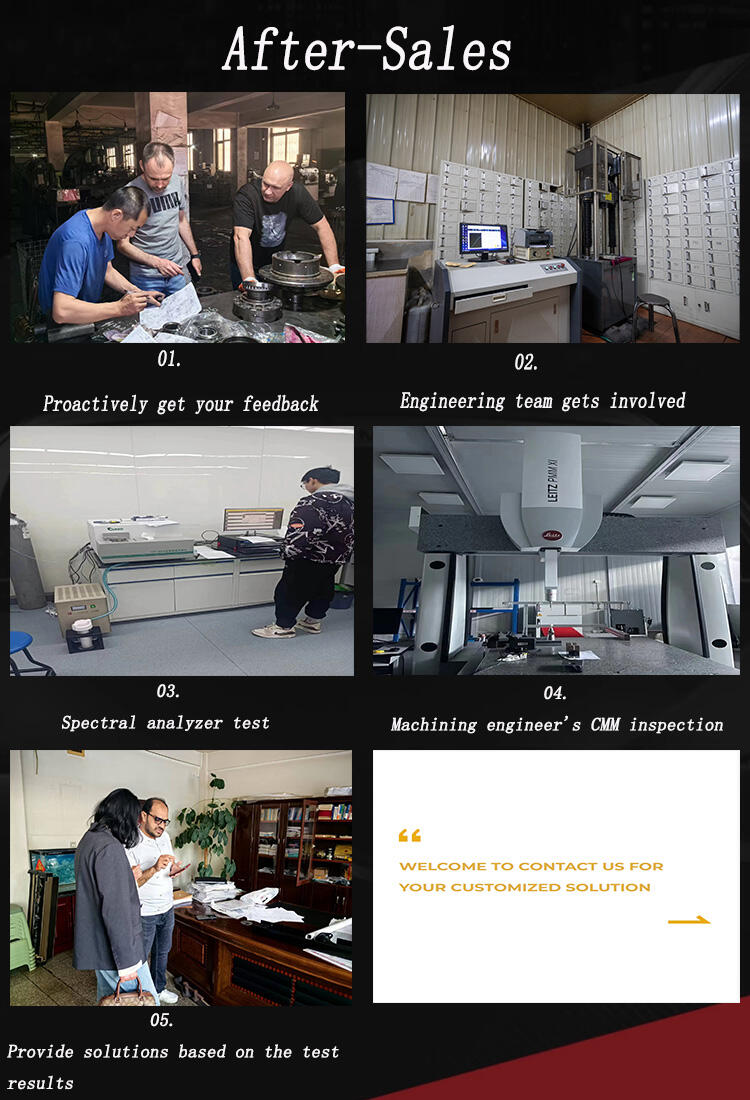

ما بعد البيع

30,000 طن+ الطاقة الإنتاجية السنوية للألمنيوم

80,000 طن+ الطاقة الإنتاجية السنوية للصلب

4000+ قوالب تطوير وإنتاج

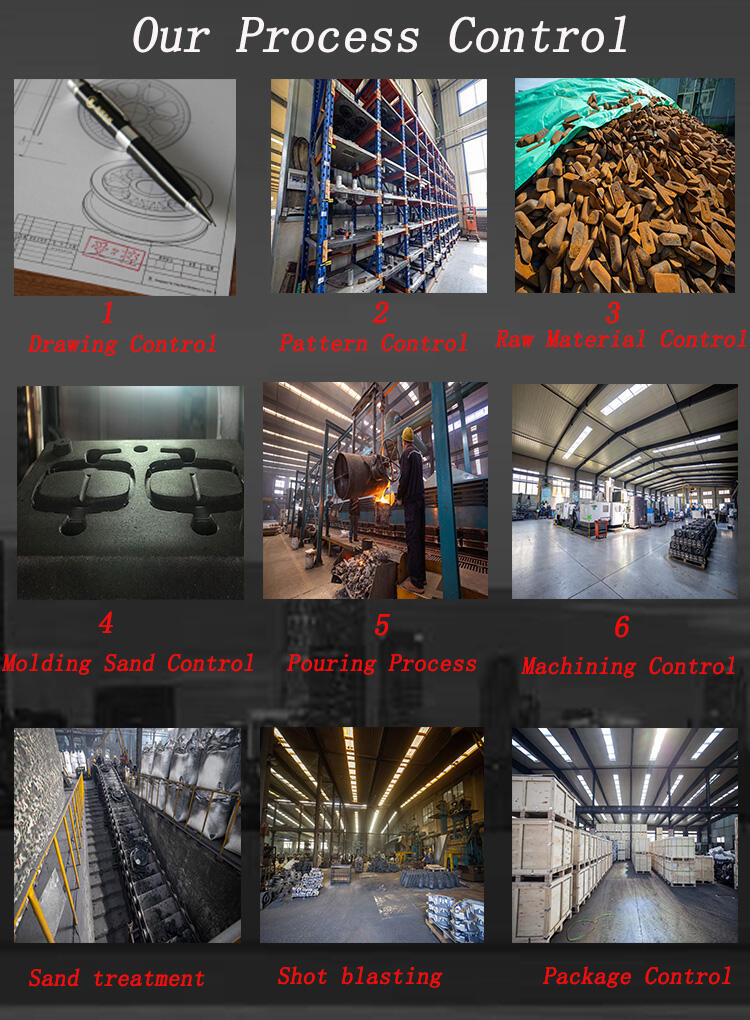

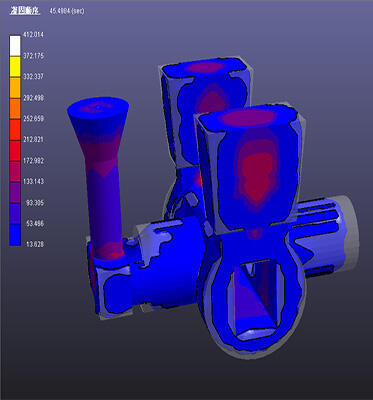

مراقبة الجودة

تحكم النمط

التحكم في المواد الخام

التحكم في الصب الخام والتجميع