- Overview

- Recommended Products

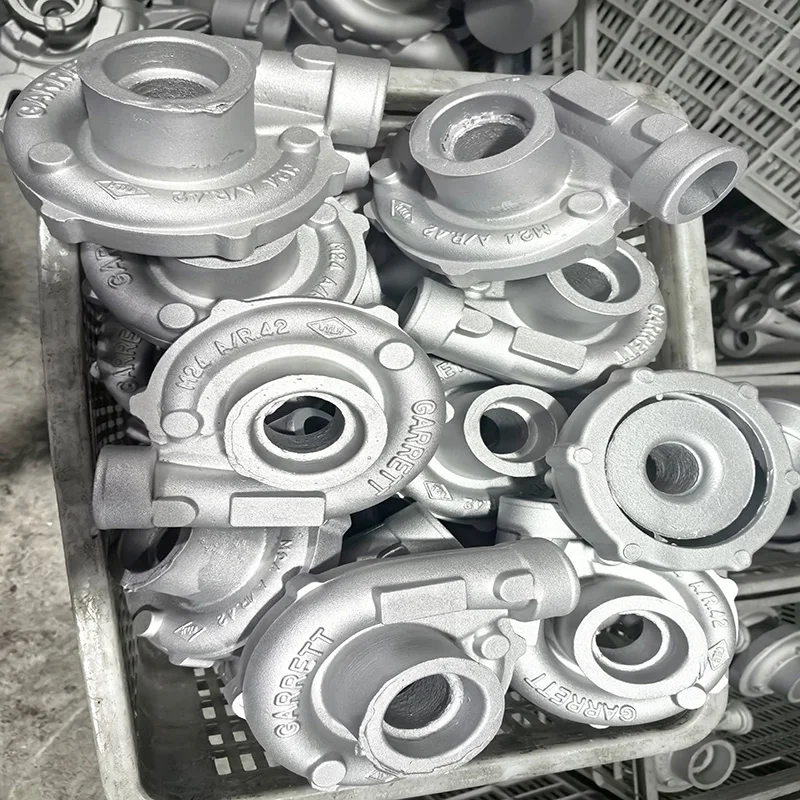

Wholesale die-casting services for aluminum parts combined with professional powder coating provide cost-effective, high-volume manufacturing solutions for industries requiring durable, precision components with superior surface finish. Our integrated approach combines advanced die-casting technology with environmentally friendly powder coating processes to deliver components that meet stringent quality standards while maintaining competitive pricing for bulk quantities.

Material Selection and Performance Characteristics

We specialize in aluminum die-casting alloys including ADC12, A380, and A360, chosen for their exceptional casting characteristics and mechanical properties:

ADC12 Aluminum: Silicon content 10.5-12.0%, copper 1.5-3.5%, tensile strength 280-320 MPa, excellent fluidity

A380 Alloy: Tensile strength 324 MPa, yield strength 159 MPa, elongation 3.5%, good machinability

A360 Aluminum: Superior corrosion resistance, tensile strength 317 MPa, pressure tightness

These materials demonstrate excellent dimensional stability, good thermal conductivity (96-140 W/m·K), and natural corrosion resistance, providing ideal substrates for powder coating applications.

Advanced Die-Casting Manufacturing Process

Our high-volume production utilizes state-of-the-art equipment and processes:

Die-Casting Operations:

Cold chamber die-casting machines with clamping forces from 250-1650 tons

High-pressure injection systems (400-800 bar) ensuring complete mold filling

Vacuum-assisted casting technology reducing porosity to ≤1%

Automated extraction and quenching systems for consistent cycle times

Multi-cavity mold designs maximizing production efficiency

Secondary Processing:

CNC machining centers maintaining tolerances within ±0.05mm

Automated trimming and deburring stations

Precision drilling and tapping operations

Quality inspection at each manufacturing stage

Powder Coating Technology:

Our powder coating process ensures durable, aesthetic finishes:

Seven-stage pretreatment including degreasing, rinsing, and chromate conversion

Electrostatic application of epoxy-polyester hybrid powders

Curing at 180-200°C for 10-15 minutes

Film thickness: 60-120 μm

Adhesion: Grade 0 (ASTM D3359)

Impact resistance: 50 kg·cm

Quality Assurance and Wholesale Advantages

Each production batch undergoes rigorous quality verification:

Material certification per ASTM standards

Dimensional inspection using CMM technology

Coating thickness measurement at multiple points

Salt spray resistance testing: 750-1000 hours

Color consistency monitoring: ΔE ≤ 1.5

Technical Specifications and Production Capabilities

Our wholesale services offer:

Annual production capacity: 5,000+ tons of aluminum components

Maximum casting dimensions: 600 × 600 × 300 mm

Minimum wall thickness: 1.0-2.5 mm achievable

Surface finish: Ra 0.8-1.6 μm after machining

Delivery capability: 50,000+ pieces monthly capacity

Industry Applications

Our die-cast and powder-coated components serve multiple sectors:

Automotive Industry:

Engine brackets and transmission components

Electronic housing and sensor mounts

Interior and exterior trim parts

Consumer Products:

Appliance components and housings

Power tool bodies and handles

Furniture hardware and fittings

Industrial Equipment:

Pump housings and valve bodies

Machinery guards and enclosures

Electrical components and heat sinks

Technical Advantages for Wholesale Buyers

Our integrated manufacturing approach delivers significant benefits:

Cost efficiency through high-volume production capabilities

Consistent quality across large quantity orders

Reduced lead times through optimized production scheduling

Single-source responsibility from casting to finished product

Technical support for design optimization and cost reduction

The combination of precision die-casting with professional powder coating creates components that withstand demanding environmental conditions while maintaining aesthetic appeal. Our wholesale services provide manufacturers with reliable, high-quality aluminum components that enhance product performance and durability while optimizing production costs through economies of scale and manufacturing expertise.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |