- Overview

- Recommended Products

In demanding industrial environments where corrosion resistance, hygiene, and load-bearing capacity are critical, our Stainless Steel Casting Pillow Block Bearing Housing provides an optimal solution for rotating equipment support. Manufactured using precision investment casting technology, these bearing housings deliver exceptional durability and performance in chemical processing, food production, marine applications, and other corrosive operating conditions. Our casting services ensure perfect dimensional stability and surface quality for reliable bearing fitment and long-term operational reliability.

Premium Stainless Steel Materials

We utilize corrosion-resistant stainless steel alloys specifically selected for bearing housing applications:

CF8/AISI 304 Stainless Steel: Ideal for general corrosion resistance in most industrial environments

CF8M/AISI 316 Stainless Steel: Superior chloride resistance for marine and chemical processing applications

CF3/CF3M Low Carbon Grades: Excellent for welded assemblies and high-temperature services

Precision Chemistry Control: Guaranteed material composition meeting ASTM A743/A744 standards

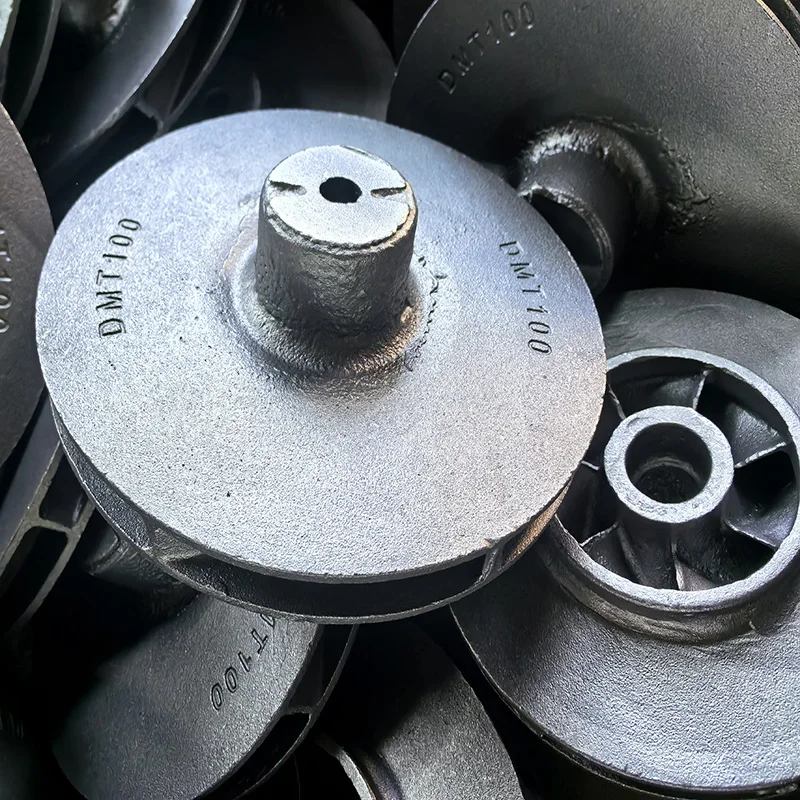

Advanced Manufacturing Process

Our investment casting process ensures superior quality bearing housings:

Precision Wax Patterns: Injection-molded patterns maintain critical dimensions for bearing seats

Ceramic Shell Building: Multi-layer ceramic molds ensure dimensional accuracy and surface finish

Controlled Pouring: Automated pouring systems maintain optimal temperature and fill characteristics

Heat Treatment: Solution annealing and stress relieving per ASTM specifications

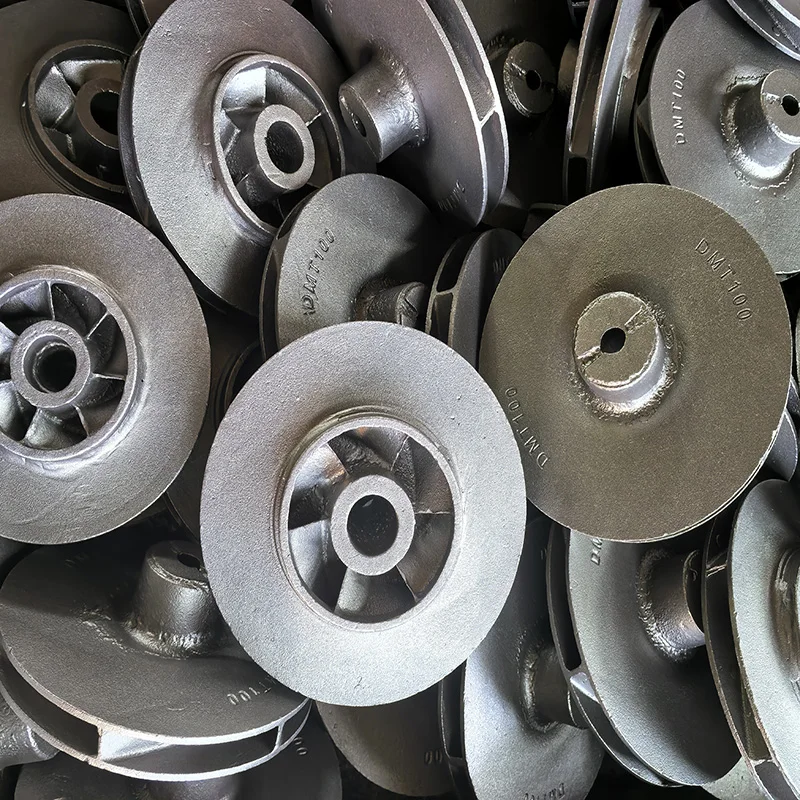

Technical Specifications

Dimensional Accuracy: CT6-8 per ISO 8062 standards

Surface Finish: 125-250 μin Ra as-cast, improvable to 32 μin with polishing

Weight Range: 1-50 kg per single housing casting

Pressure Tightness: 100% leak testing available for sealed housing applications

Quality Assurance

Radiographic Testing: Detection of internal defects in critical stress areas

Dimensional Verification: CMM inspection of bearing seats and mounting surfaces

Material Certification: Mill test reports with full traceability

Mechanical Testing: Tensile and impact testing per customer requirements

Application-Specific Design Features

Standard & Custom Designs: Available in standard SN, SAF, and FLANGE series or fully customized

Sealing Integration: Optimized for various sealing systems including labyrinth and lip seals

Mounting Configuration: Multiple base designs for different installation requirements

Lubrication Compatibility: Suitable for oil and grease lubrication systems

Industry Applications

Food & Beverage Processing: Washdown environments requiring sanitary construction

Chemical Processing: Resistance to acidic and alkaline media

Marine & Offshore: Saltwater corrosion resistance

Pharmaceutical Manufacturing: Cleanroom compatibility and sterilizability

Water Treatment Plants: Chloride and chemical resistance

Partner with our foundry for stainless steel pillow block bearing housings that combine corrosion resistance with mechanical reliability. Our precision casting expertise ensures perfect bearing fitment, extended service life, and reduced maintenance costs in your most demanding applications.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |