- Overview

- Recommended Products

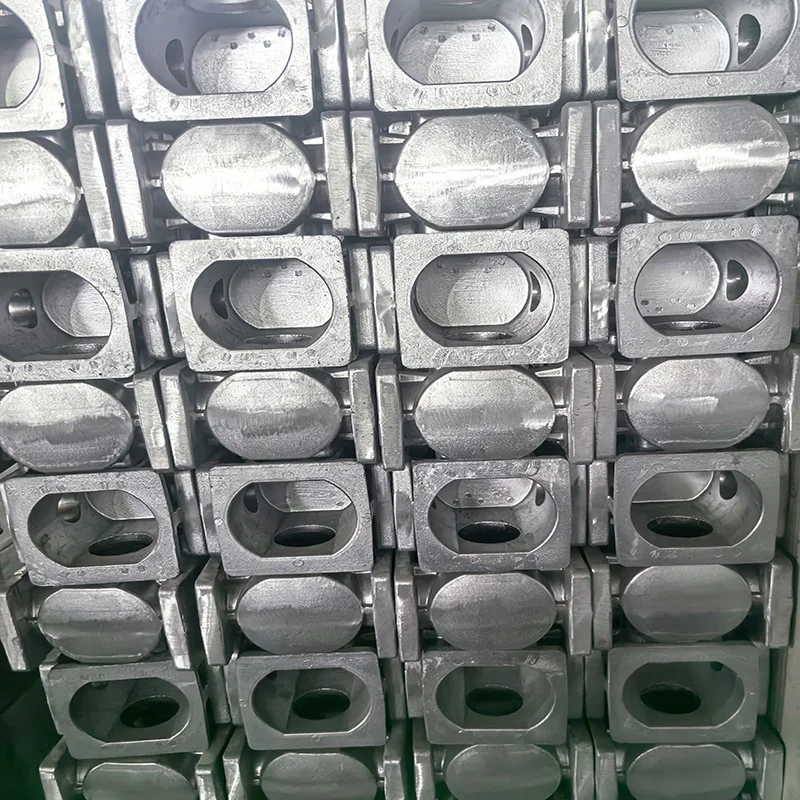

In the realm of industrial machinery components, the TCW125 Speed Reducer Gearbox stands as a critical power transmission element, manufactured through advanced aluminum gravity casting processes to ensure exceptional durability and performance. This precision-engineered component represents the perfect marriage of material science and manufacturing expertise, delivering reliable operation in demanding industrial environments.

Superior Aluminum Material Properties

The TCW125 gearbox housing utilizes high-strength aluminum alloys specifically formulated for gravity casting applications. These alloys, including A356 and similar grades, provide an optimal balance of mechanical properties and castability . With precise chemical composition control including silicon content of 5.5-6.5% and magnesium content of 0.25-0.45%, these alloys develop enhanced mechanical properties through T6 heat treatment, achieving tensile strength exceeding 290 MPa and hardness greater than HRB 45 . The resulting material structure offers excellent corrosion resistance, good machinability, and superior weight-to-strength ratios compared to traditional cast iron components.

Precision Gravity Casting Manufacturing

The gravity casting process employed in TCW125 production involves pouring molten aluminum into precision molds under Earth's gravitational force . This manufacturing approach delivers significant advantages over alternative methods, including reduced internal gas porosity and improved mechanical properties due to controlled solidification patterns . Unlike high-pressure die casting, gravity casting produces components with superior dimensional stability and the capability for subsequent heat treatment enhancement .

Our manufacturing facilities employ computer-aided mold design and precision temperature control systems throughout the casting process, ensuring consistent results across production batches. The process achieves casting tolerances within ±0.2mm and produces surfaces with roughness values between Ra 12.5-25, minimizing the need for extensive post-processing operations .

Enhanced Performance Characteristics

The aluminum gravity casting approach delivers gearbox housings with exceptional operational characteristics:

Excellent Vibration Damping: The aluminum structure effectively absorbs operational vibrations, reducing noise transmission and extending component lifespan

Superior Heat Dissipation: Aluminum's natural thermal conductivity (approximately 0.34-0.37 cal/cm²/cm/°C) prevents heat buildup in continuous operation

Reduced Weight: Aluminum construction provides significant weight savings over cast iron alternatives, facilitating easier installation and handling

Outstanding Corrosion Resistance: The housing maintains structural integrity in challenging industrial environments, including those with moderate chemical exposure

Dimensional Stability: The casting maintains precision under variable operational temperatures and loading conditions

Rigorous Quality Assurance

Every TCW125 gearbox housing undergoes comprehensive quality verification to ensure consistent performance:

Material Certification: Verification of chemical composition and mechanical properties

Dimensional Inspection: Coordinate measuring machine validation of critical interfaces and mounting surfaces

Non-Destructive Testing: X-ray inspection confirming internal soundness and absence of defects

Performance Validation: Operational testing under simulated working conditions

Our quality management system maintains ISO 9001:2008 certification, with all components accompanied by complete material inspection reports and dimensional verification documentation .

Industrial Application Versatility

The TCW125 Aluminum Gravity Cast Gearbox serves diverse power transmission requirements across multiple sectors:

Construction Machinery: Tower cranes, concrete mixers, and hoisting equipment requiring reliable speed reduction

Industrial Automation: Conveyor systems, processing equipment, and material handling applications

Agricultural Equipment: Tractors, harvesters, and irrigation systems demanding corrosion-resistant components

Transportation Infrastructure: Elevators, escalators, and moving walkways in public spaces

Technical Specifications

Minimum Order Quantity: 100kg

Standard Compliance: GB standards with ISO 9001:2008 certification

Casting Tolerance: ±0.2mm

Dimensions: 303×317×354mm (standard)

Surface Treatment: Deburring and basic finishing

Heat Treatment Capability: T5, T6 temper options available

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |