- Overview

- Recommended Products

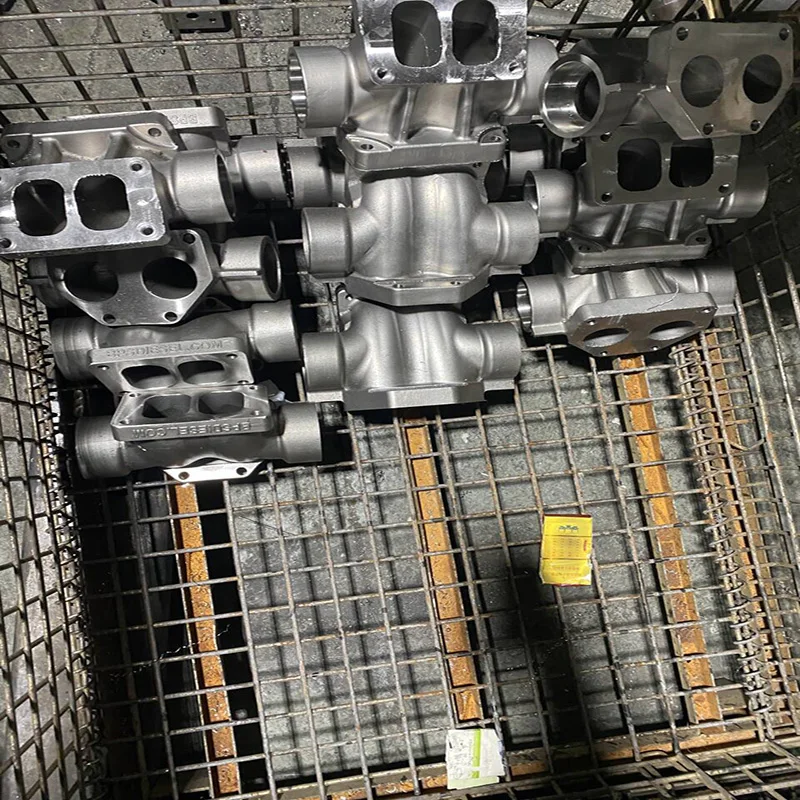

In the world of advanced manufacturing, precision components demand exceptional accuracy and flawless surface quality. Our Precision Casting Services utilizing the Lost Wax Investment Technique deliver exactly that - complex, high-tolerance parts with outstanding metallurgical properties, ready for minimal post-processing.

Advanced Materials for Demanding Applications

We process an extensive range of engineering alloys to meet your specific requirements:

Stainless Steels: 304, 316, 17-4PH for corrosion resistance and strength

Tool Steels: H13, P20 for durability in demanding environments

Aluminum Alloys: A356, 7075 for lightweight structural components

Super Alloys: Inconel, Hastelloy for extreme temperature applications

Copper Alloys: Brass, bronze for thermal and electrical conductivity

The Lost Wax Investment Casting Process

Our meticulous approach ensures consistent, high-quality results:

-

Pattern Creation

Injection molding of wax patterns using precision aluminum molds

Assembly of wax patterns into clusters for efficient production

-

Shell Building

Successive ceramic coatings applied via dipping and stuccoing

Controlled drying between each coating application

Final shell thickness tailored to part size and material

-

De-waxing and Firing

Advanced steam autoclave systems for complete wax removal

High-temperature firing to achieve optimal shell strength

-

Pouring and Finishing

Controlled atmosphere melting and pouring

Automated shell removal and cut-off operations

Heat treatment and surface finishing as required

Key Advantages of Our Process

Exceptional dimensional accuracy with tolerances up to ±0.005 inches

Superior surface finishes ranging from 125 to 250 RMS

Complex geometries with intricate details and thin walls

Minimal material waste and reduced machining requirements

Industry Applications

Our investment casting capabilities serve diverse sectors:

Aerospace: Turbine blades, engine components, structural parts

Medical: Surgical instruments, implantable devices, dental components

Automotive: Engine parts, transmission components, fuel system elements

Industrial: Valve bodies, pump impellers, machinery components

Firearms: Precision triggers, hammers, and small components

Quality Assurance

Every component undergoes rigorous verification:

First-article inspection and statistical process control

Dimensional validation with CMM and optical comparators

Non-destructive testing including X-ray and liquid penetrant

Material certification and mechanical testing

Our Lost Wax Investment Casting expertise combines traditional craftsmanship with modern technology, delivering components that meet the most demanding specifications. With rapid prototyping capabilities and production volumes from prototypes to thousands of pieces, we provide comprehensive solutions for your precision casting needs.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |