- Overview

- Recommended Products

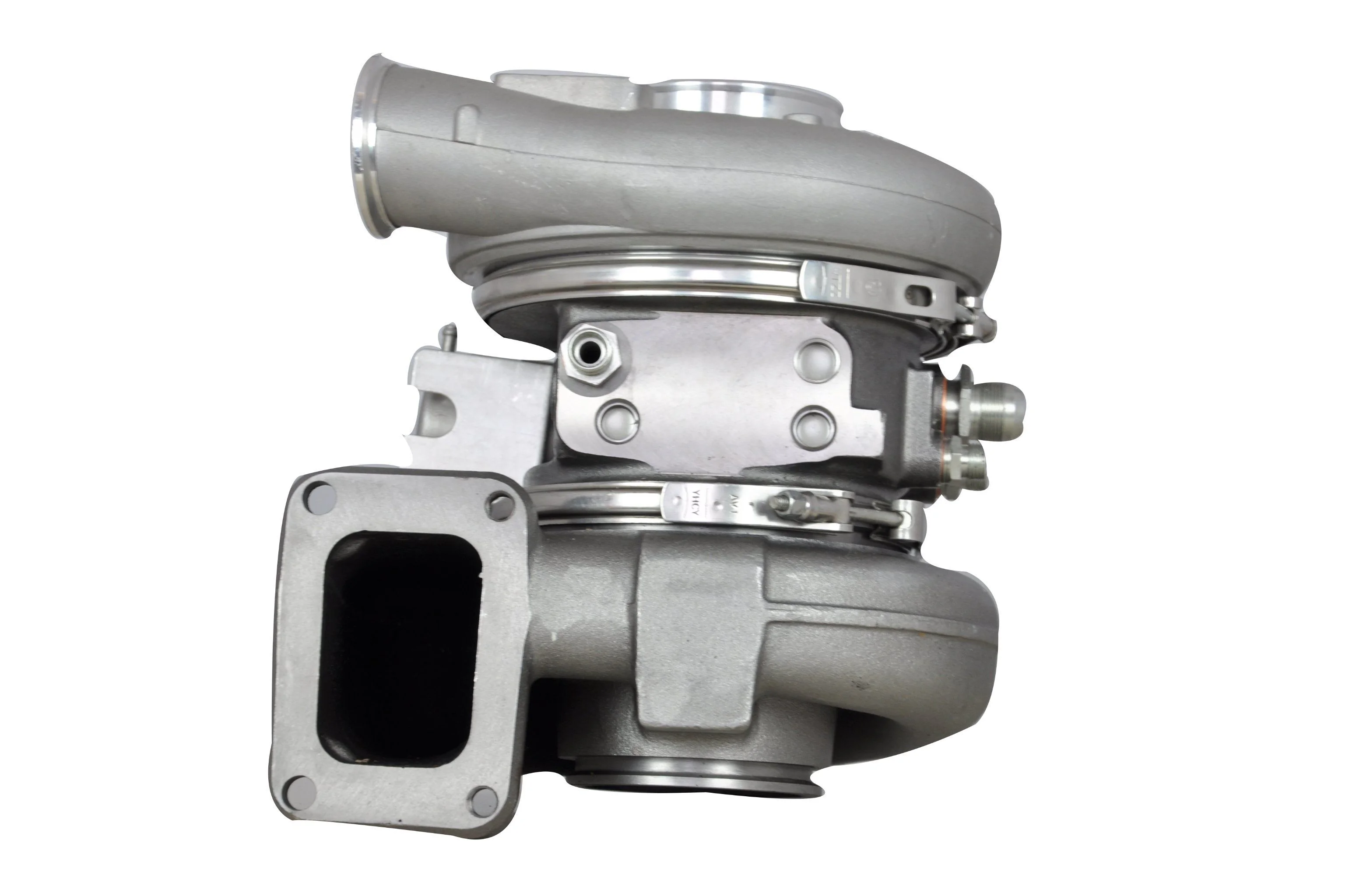

For automotive OEMs seeking reliable performance under extreme conditions, our specialized turbocharger manifold pipe casting services deliver precision-engineered solutions that withstand the most demanding operating environments. We combine advanced metallurgical expertise with sophisticated manufacturing processes to produce components that meet rigorous automotive industry standards for performance and durability.

Advanced Material Engineering

We utilize high-performance alloys specifically formulated for turbocharger applications:

Heat-Resistant Stainless Steels (AISI 304H, 321H, 316L) offering exceptional oxidation resistance and high-temperature strength

Silicon Molybdenum Ductile Iron (SiMo 4.5/5.0) providing superior thermal fatigue resistance and creep strength

High-Nickel Super Alloys (Inconel 713C, X-750) for extreme temperature applications exceeding 950°C

All materials undergo rigorous chemical analysis and mechanical testing to ensure consistent performance across production batches.

Precision Manufacturing Process

Our integrated manufacturing approach ensures optimal component quality:

Shell Molding Technology - Produces complex thin-wall geometries with excellent dimensional stability and surface finish quality

Investment Casting Process - Delivers intricate internal passages and precise turbine interfaces with minimal machining requirements

Computer-Controlled Machining - Full CNC processing of mounting flanges, wastegate ports, and sensor interfaces with tight tolerance control

Comprehensive Heat Treatment - Solution annealing and aging processes to optimize material microstructure and mechanical properties

Performance Advantages

Superior Thermal Fatigue Resistance - Withstands repeated thermal cycling from ambient to 800°C+ operating temperatures

Excellent Creep Strength - Maintains structural integrity under continuous high-temperature service

Optimized Fluid Dynamics - Smooth cast surfaces and precise geometries minimize exhaust gas restriction

Enhanced Oxidation Resistance - Special alloy formulations resist degradation from hot corrosive exhaust gases

Proven Durability - Extensive validation testing confirms long-term reliability under real-world conditions

Quality Assurance

Our comprehensive quality management system includes:

In-process dimensional verification using coordinate measuring machines

Liquid penetrant and radiographic inspection for defect detection

Pressure testing and flow bench validation of finished components

Material certification and traceability throughout the supply chain

Industry Applications

Passenger vehicle turbocharged engines

Commercial vehicle diesel powertrains

High-performance and racing applications

Industrial and marine turbocharger systems

As an established OEM supplier, we maintain full IATF 16949 certification and support customer-specific requirements from prototype development through high-volume production. Contact our engineering team to discuss your turbocharger component needs and discover how our casting expertise can enhance your powertrain performance.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |