New & Used FAW Cast Iron Flywheel for TOYOTA 1HZ Hilux Auto Parts Engine for Truck & Car Air Shipping

- Overview

- Recommended Products

For Toyota 1HZ engine owners seeking reliable replacement solutions, our New & Used FAW cast iron flywheels offer the perfect balance of performance and value. Specifically engineered for compatibility with TOYOTA 1HZ Hilux engines, these durable components are available with global air shipping to ensure quick delivery for both truck and car applications. Whether you're maintaining a fleet or restoring a classic vehicle, our flywheels deliver the quality and precision that Toyota engines demand.

Material Excellence: High-Quality Cast Iron

Our flywheels are manufactured from premium materials to ensure long-lasting performance:

Grade 25 Gray Cast Iron: Delivering excellent vibration damping properties and thermal stability

Precision-Balanced Construction: Ensuring smooth operation across the entire RPM range

Heat-Treated Surfaces: Providing enhanced wear resistance for extended service life

Micro-alloyed Composition: Optimized for strength and durability under high-torque conditions

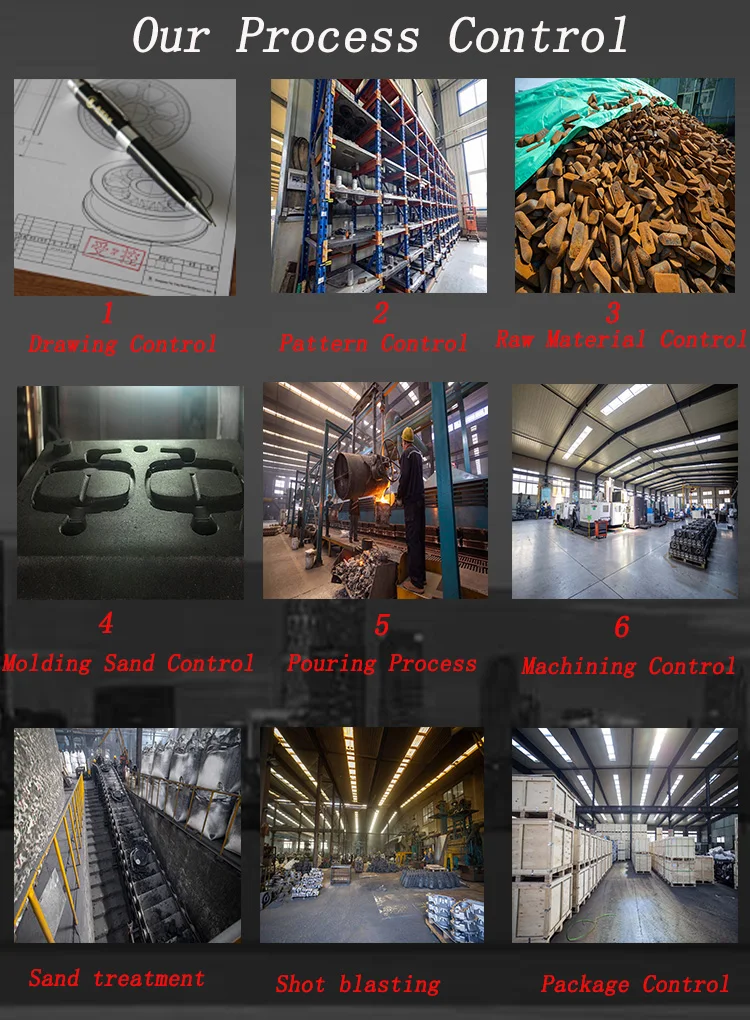

Manufacturing Process & Quality Assurance

Each flywheel undergoes rigorous production and testing procedures:

-

Sand Casting Process

Resin-bonded molding for dimensional accuracy

Controlled cooling cycles to prevent internal stresses

Machining allowance optimization for precise finishing

-

Precision Machining

CNC turning and grinding for exact dimensional specifications

Surface finishing to Ra 1.6-3.2 μm for optimal clutch engagement

Bolt hole machining within ±0.05mm positional tolerance

-

Quality Validation

Dynamic balancing to within 15 g-cm

Magnetic particle inspection for defect detection

Hardness testing to ensure proper material properties

Performance Characteristics

Excellent Heat Dissipation: Maintaining performance under repeated clutch engagements

Superior Surface Hardness: 180-220 HB for optimal wear resistance

Precision Ring Gear Fitment: Ensuring reliable engine starting performance

Vibration Damping: Reducing noise and harshness in the drivetrain

Applications & Compatibility

Toyota 1HZ Diesel Engines (1990-2007)

Toyota Hilux 4x4 models

Land Cruiser 70/80 series

Compatible with standard clutch assemblies

Global Availability

New OEM-quality replacements with full warranty coverage

Quality inspected used units for budget-conscious applications

Express air shipping available worldwide

Complete documentation and customs support

Restore your Toyota 1HZ engine to peak performance with our reliable FAW cast iron flywheels. Contact us today for availability and shipping options to your location.

About Us

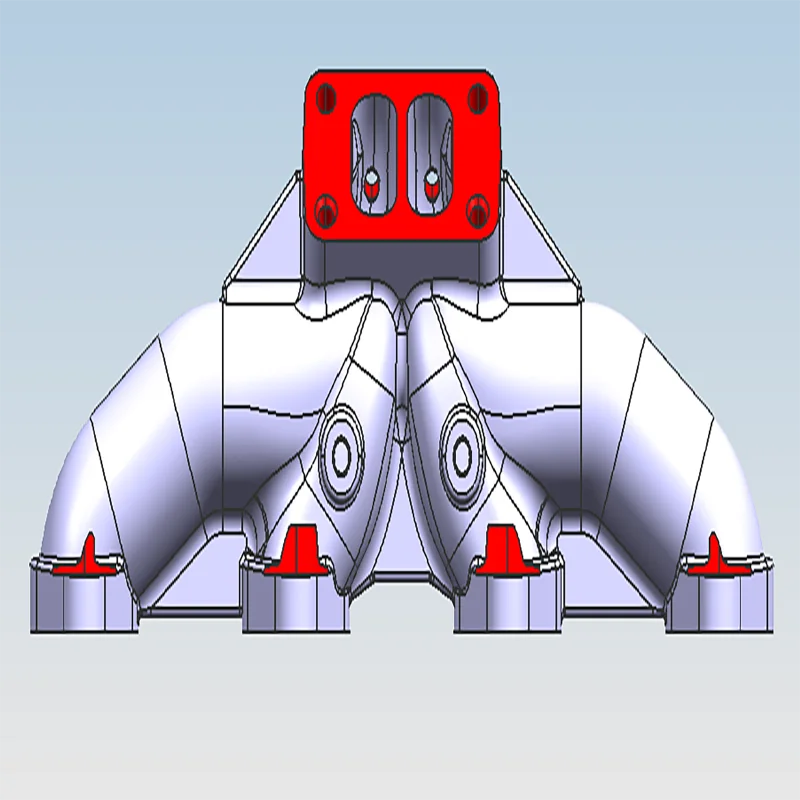

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

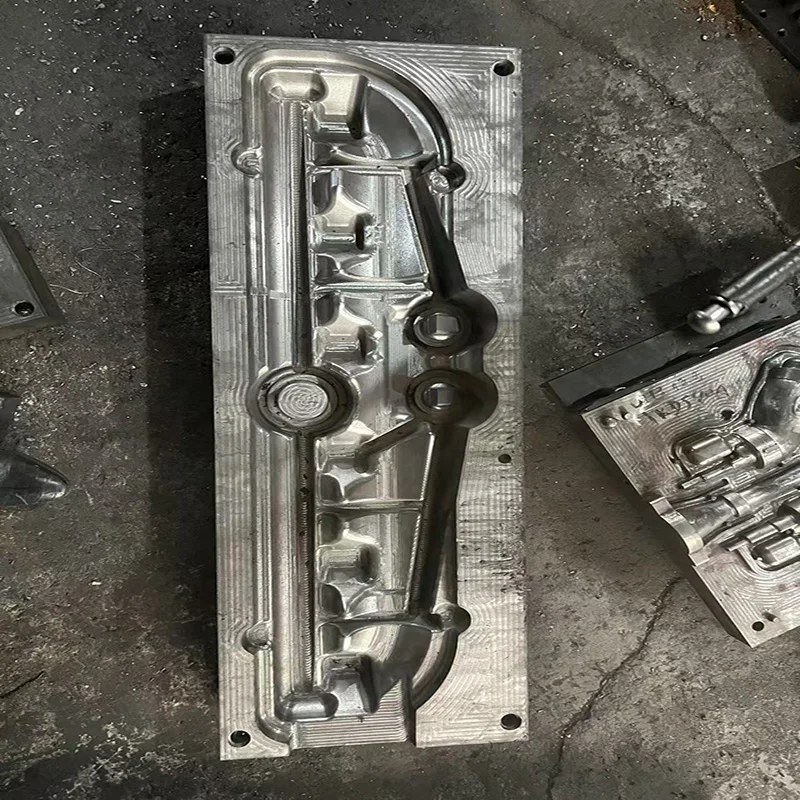

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control