- Overview

- Recommended Products

In the demanding field of fluid handling and transfer, the reliability of pump components is critical. Our specialized Low Pressure Aluminum Metal Centrifugal Pump Gravity Casting Services provide an optimal manufacturing solution for producing robust, high-integrity pump housings, impellers, and other critical parts. This article explores how this specific combination of casting techniques delivers components that meet the rigorous standards of the pump industry.

Superior Material and Performance Characteristics

We utilize high-grade aluminum alloys, such as A356.2, known for their excellent corrosion resistance, good machinability, and favorable strength-to-weight ratio. The low-pressure casting process, combined with gravity pouring techniques for certain geometries, ensures these inherent material properties are fully realized in the final product. The result is a pump component with a dense, homogeneous microstructure that offers exceptional pressure tightness—a non-negotiable requirement for preventing leaks in pump systems. Furthermore, these cast parts exhibit excellent resistance to cavitation erosion and can withstand the dynamic loads encountered during pump operation, ensuring long service life and reduced maintenance.

Precision-Controlled Production Process

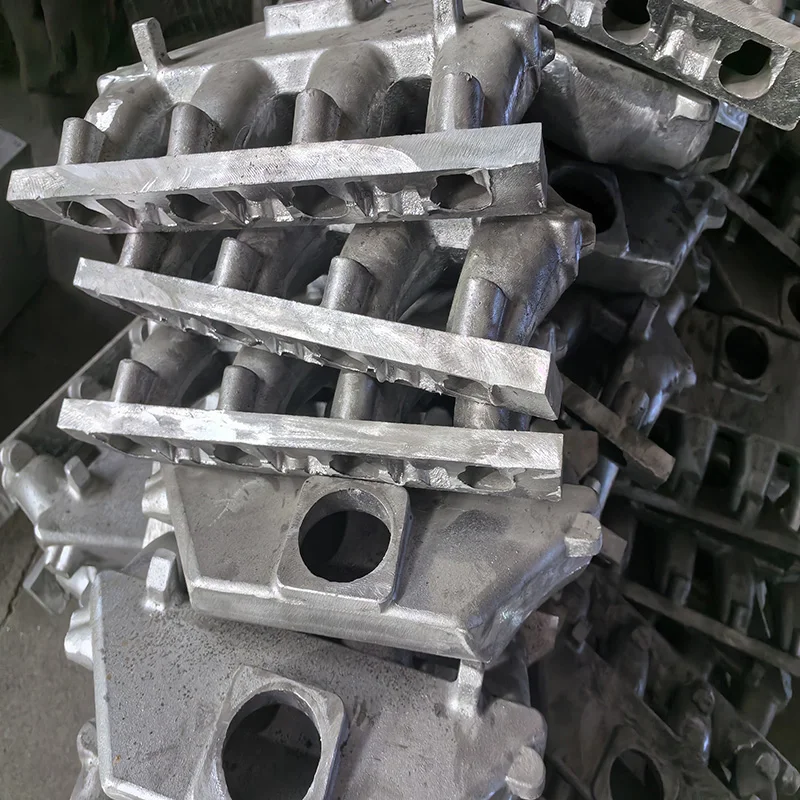

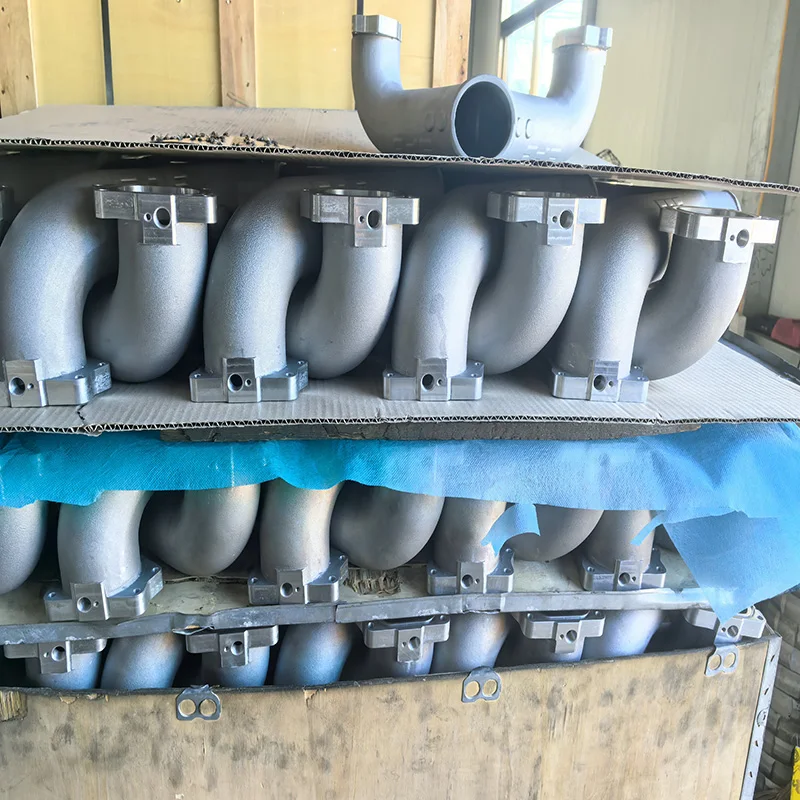

Our Low Pressure Aluminum Casting process is specifically engineered for quality and consistency. Molten aluminum is fed into the mold from the bottom via a riser tube, using low pressure (typically 0.5-1 bar) from a compressed air source. This controlled, bottom-up filling minimizes turbulence and oxide formation, drastically reducing gas porosity and inclusions. For complex internal passages typical of centrifugal pump volutes and impellers, precision-machined sand cores are often incorporated into the permanent mold (a semi-permanent mold process). This allows for the creation of intricate waterways with excellent surface finish and dimensional accuracy. The gradual solidification under pressure further enhances metallurgical soundness, yielding parts that are structurally superior and reliably leak-proof.

Critical Applications in Fluid Handling Systems

The components produced through our services are essential across numerous sectors where dependable fluid transfer is paramount. Key applications include:

Centrifugal Pump Housings (Volutes): Providing the critical pressure-containing casing.

Impellers and Diffusers: Featuring complex vanes that are cast with high precision for optimal hydraulic efficiency.

Brackets and Mounting Plates: Offering structural support for the pump assembly.

Industrial & Chemical Processing: For pumps handling various coolants and non-highly corrosive fluids.

Water Treatment & Irrigation Systems: Where corrosion resistance and durability are key.

Marine and Automotive: For coolant and circulation pumps.

By leveraging our specialized Low Pressure and Gravity Casting capabilities, we provide OEMs with pump components that guarantee performance, longevity, and reliability, making them the preferred choice for critical fluid handling applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |