- Overview

- Recommended Products

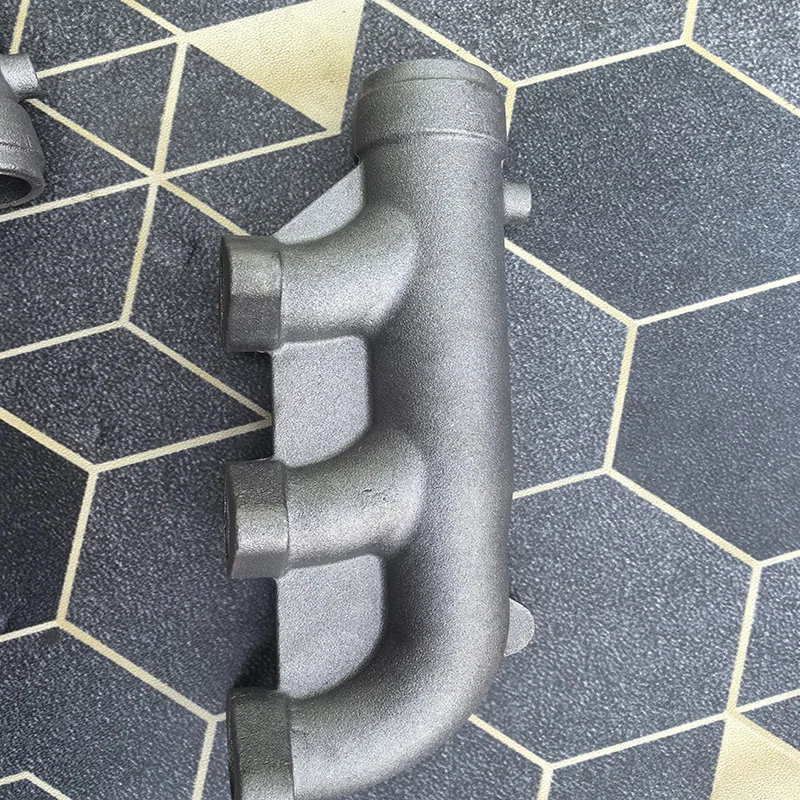

For automotive enthusiasts and performance specialists working with 1.8T engine platforms, the turbo manifold represents a critical component that directly impacts power output and thermal management. Our ISO9001 certified manufacturing facility specializes in producing Customized Iron Casting Turbo Manifolds specifically engineered for 1.8T applications, delivering OEM-quality fitment, superior thermal performance, and enhanced durability for both street and track applications.

Premium Material Engineering

We utilize high-silicon molybdenum iron (SiMo 4.5/5.1) specifically formulated for high-temperature turbocharger applications. This specialized alloy delivers:

Exceptional thermal stability maintaining structural integrity up to 850°C

Superior thermal fatigue resistance withstanding repeated heating/cooling cycles

High creep resistance under sustained turbocharger temperatures

Optimal oxidation resistance in direct exhaust gas environments

Minimum tensile strength of 250 MPa at 800°C operating temperature

All materials comply with ASTM A319 Grade II specifications and undergo rigorous spectrochemical analysis to ensure consistent high-temperature performance and microstructural integrity.

Advanced Manufacturing Process

Our ISO9001 certified production integrates sophisticated foundry technology with precision machining:

Precision Casting Technology

Ceramic shell investment casting for complex runner geometries

CAD-optimized gating systems ensuring proper metal flow

Controlled atmosphere pouring preventing surface defects

Real-time thermal monitoring during solidification

Precision Machining

5-axis CNC machining of flange surfaces (flatness within 0.1mm)

Precision boring of turbocharger mounting interface

Coordinate measuring machine verification of all critical dimensions

Surface finishing to Ra 3.2-6.3 μm for optimal gasket sealing

Performance Characteristics

Our turbo manifolds deliver:

Optimized exhaust gas flow with equal-length runner design

Maximum continuous operating temperature of 800°C

Pressure capability exceeding 3 bar boost pressure

Minimal thermal expansion distortion under cycling conditions

Perfect compatibility with OEM and aftermarket turbochargers

Quality Assurance Protocol

Each manifold undergoes comprehensive validation:

Dimensional inspection using optical scanning technology

Pressure testing to 5 bar for leak prevention

Magnetic particle inspection for surface defect detection

Material certification with full traceability documentation

High-temperature thermal cycling testing

Technical Applications

Our custom turbo manifolds are engineered for:

Volkswagen/Audi 1.8T engine performance applications

Both street performance and competition use

Various frame turbocharger configurations

OEM replacement and upgrade applications

Our engineering team provides complete technical support including:

Flow optimization for specific power targets

Thermal management solutions

Custom flange configurations

Integrated wastegate mounting options

By combining ISO9001 quality management with advanced casting technology, we deliver turbo manifolds that ensure reliable high-performance operation, extended service life, and optimal power delivery for 1.8T engine platforms. Our certified manufacturing processes guarantee consistent quality and performance that meets the demands of both professional installers and performance enthusiasts.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |