- Overview

- Recommended Products

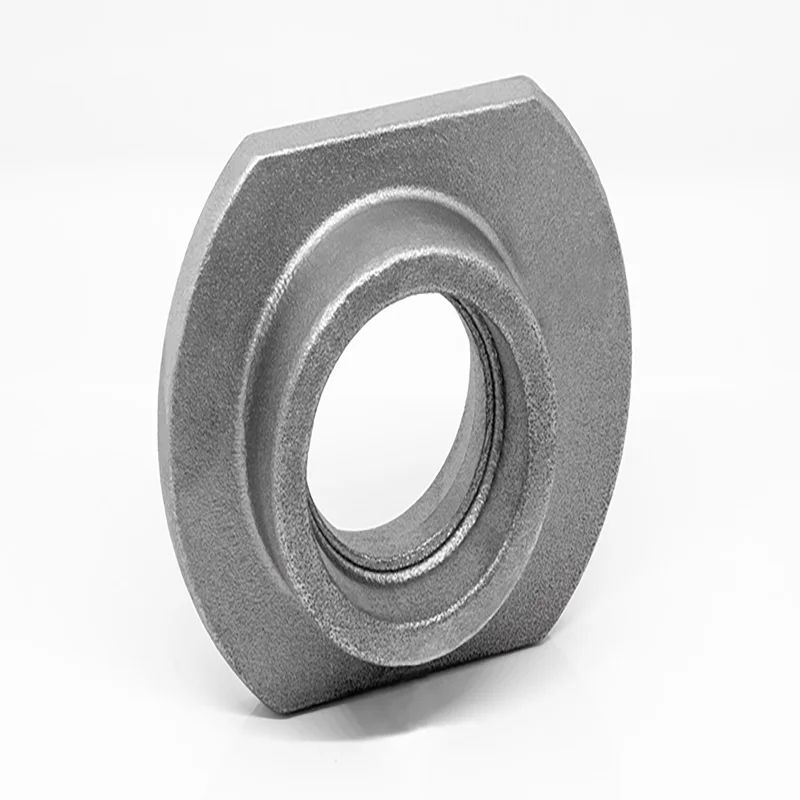

Introducing, Pengxin's high-quality custom made metal hot forging services, designed to provide customers with rich experiences and top-notch products. Our team of skilled craftsmen utilize advanced techniques and state-of-the-art equipment to create custom metal components that exceed industry standards.

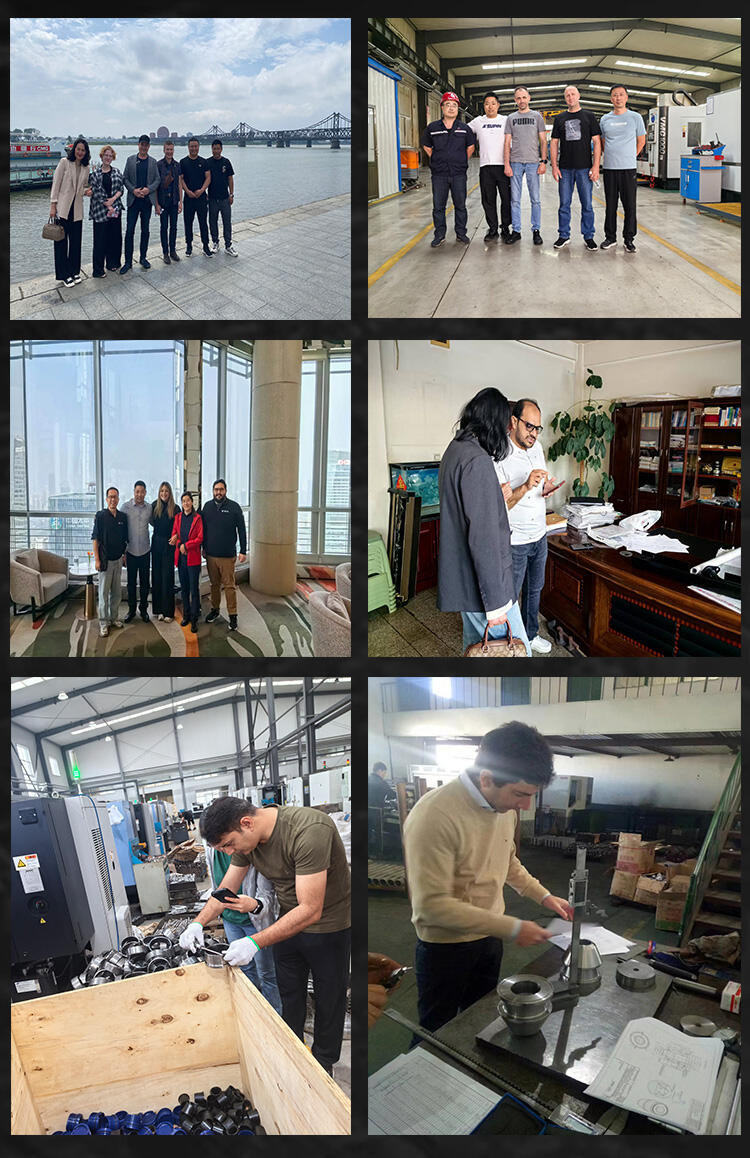

At Pengxin, we understand the importance of precision and quality when it comes to metal forging. That's why we take great care in every step of the process, from initial design to final inspection. Our experienced engineers work closely with customers to understand their specific needs and requirements, ensuring that each product is tailor-made to perfection.

Using only the finest materials and cutting-edge technology, we are able to produce custom metal forgings that are not only durable and reliable, but also aesthetically pleasing. Whether you need a single prototype or a large batch of components, Pengxin is equipped to handle projects of any size and complexity with ease.

Our custom made metal hot forging services are ideal for a wide range of industries, including automotive, aerospace, construction, and more. From small intricate parts to large structural components, we have the expertise and capability to deliver top-quality products that meet your exact specifications.

In addition to our commitment to quality, Pengxin also values customer satisfaction and strives to provide a seamless experience from start to finish. Our dedicated team is always ready to assist with any questions or concerns, ensuring that your project is completed on time and within budget.

Experience the difference that Pengxin's custom made metal hot forging services can make for your next project. Contact us today to learn more about how we can help bring your design ideas to life with precision, expertise, and unmatched quality. Trust Pengxin for all your metal forging needs and discover the difference that quality and craftsmanship can make

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvanized etc |

||||||

Size |

Customized |

||||||

Surface treatment |

Powder coating, electroplating, oxide, anodization |

||||||

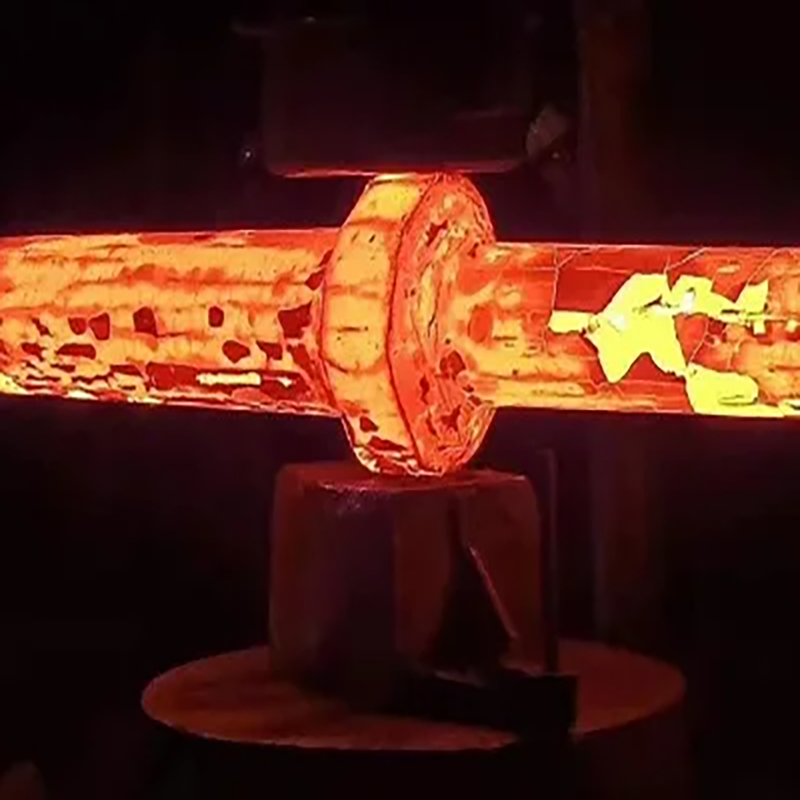

Technics |

laser cut, bend, weld, stamp, casting, forging |

||||||

Certification |

ISO9001:2015 |

||||||

OEM |

Accept |

||||||

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

||||||

Color |

Customized |

||||||

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

||||||

Who We Are

Pre-sales

On Sale

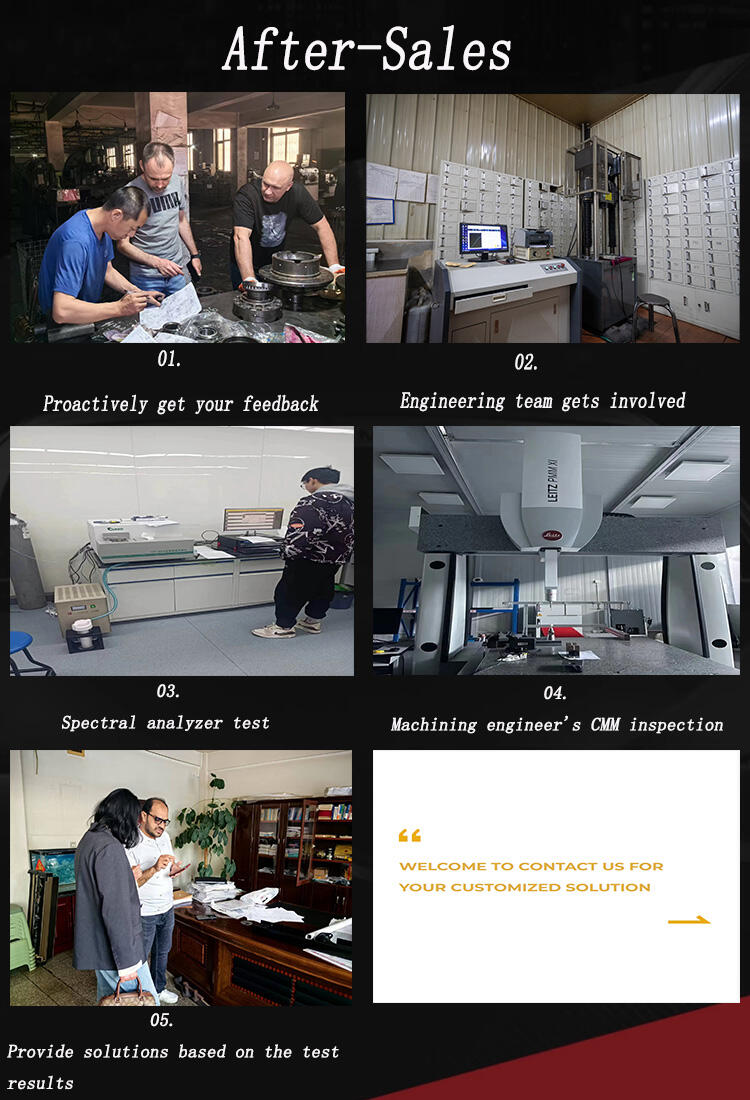

After-Sales

30,000 tons+Annual production capacity for Aluminum

80,000 tons+Annual production capacity for Steel

4000+Mold develop production

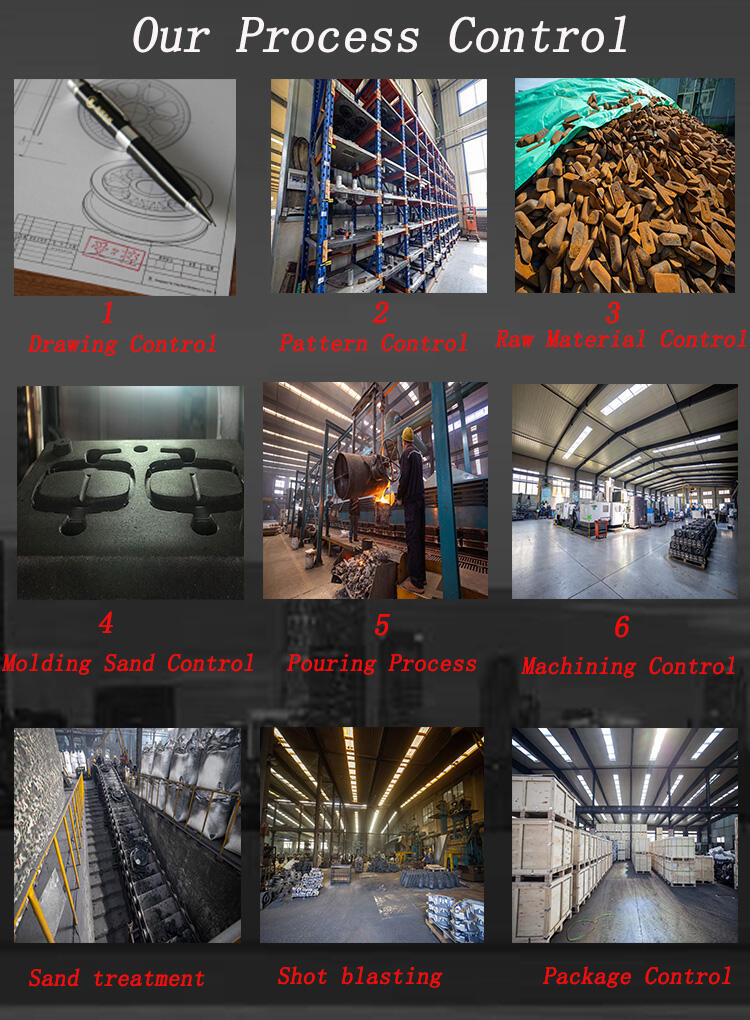

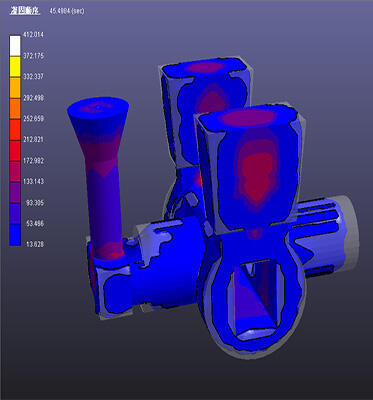

Quality Control

Pattern Control

Raw Material Control

Raw Casting & Machining Control