- Overview

- Recommended Products

In the competitive automotive manufacturing sector, precision brass CNC lathe components deliver exceptional performance for critical vehicle systems. These specialized parts combine superior material properties with advanced manufacturing techniques to meet the demanding requirements of modern automotive applications.

Advanced Brass Material Selection

Automotive brass components utilize specialized alloys engineered for specific performance characteristics:

Leaded Brass Alloys (C36000, C38500) contain 1.5%-3.7% lead content that significantly enhances machinability while maintaining excellent mechanical properties . These alloys demonstrate free-cutting characteristics that enable high-speed production with minimal tool wear . The copper content ranging from 55%-63% provides the fundamental corrosion resistance and structural integrity required for automotive applications .

Environmental Compliance Alloys are being developed to meet increasing regulatory requirements while maintaining performance standards . These emerging materials typically reduce lead content to below 1.8% while incorporating alternative elements to preserve machining characteristics .

Enhanced Performance Characteristics

Brass components manufactured for automotive applications deliver:

Excellent corrosion resistance against automotive fluids, coolants, and environmental exposure

Superior machinability with cutting speeds up to 30% faster than standard brass alloys

Good mechanical properties with tensile strength reaching 510 MPa and hardness up to 120 HB

Natural lubricity reducing friction in moving assemblies and extending component lifespan

Thermal conductivity effectively dissipating heat from critical automotive systems

Precision Manufacturing Capabilities

Our manufacturing processes integrate advanced technologies to ensure consistent quality:

CNC Lathe Machining

Modern CNC lathe systems utilize multi-axis configurations capable of producing complex geometries with tolerances within ±0.005mm . Automated production lines incorporate live tooling capabilities and sub-spindle technology for complete machining in single setups, significantly reducing production time while maintaining dimensional accuracy .

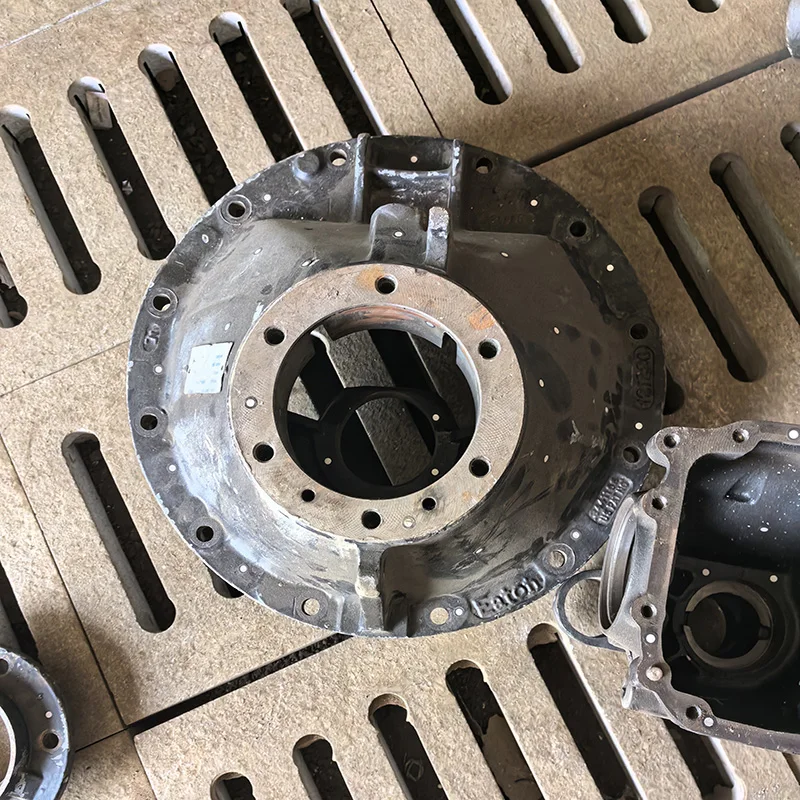

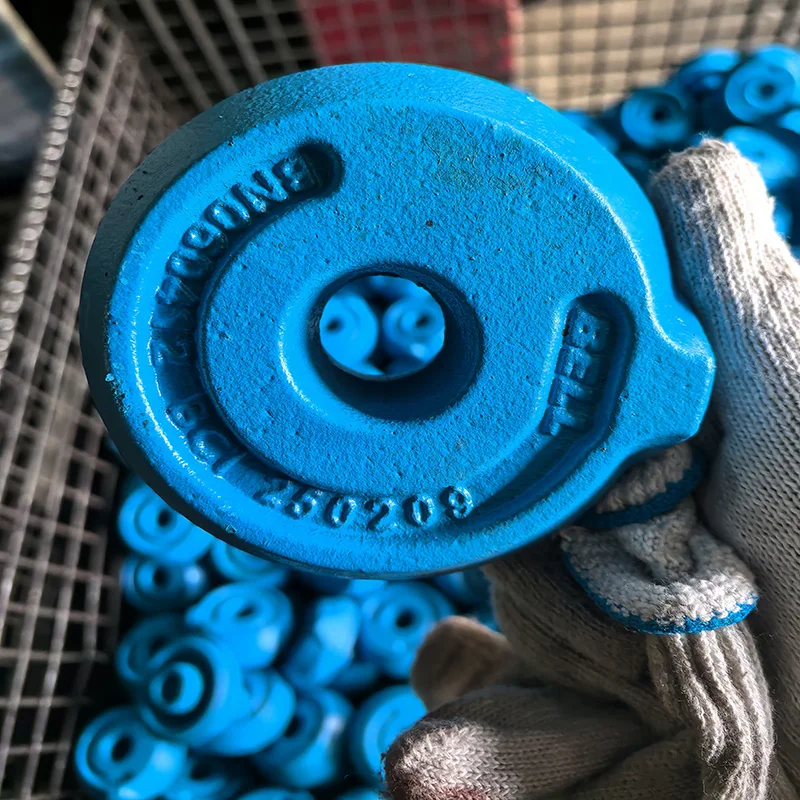

Premium Casting Services

Complementary casting processes produce near-net-shape components with minimal machining requirements . Precision investment casting techniques create complex internal passages and external contours ideal for automotive fluid handling applications .

Integrated Quality Assurance

Comprehensive inspection protocols include:

Statistical process control monitoring key parameters throughout production

Coordinate measuring machine verification of critical dimensions

Material certification confirming composition and mechanical properties

Performance testing simulating automotive operating conditions

Automotive Application Range

Our brass components serve critical functions across vehicle systems:

Fuel and Emissions Systems

Fuel injector components requiring precise tolerances and chemical resistance

Carburetor parts demanding excellent machining characteristics and durability

Emissions control valves needing reliable operation under varying temperature conditions

Electrical and Electronic Systems

Sensor housings protecting sensitive electronic components from environmental factors

Connector terminals providing superior electrical conductivity and corrosion resistance

Grounding components ensuring reliable electrical system performance

Mechanical Systems

Bushing and bearing applications utilizing brass's natural lubricity and wear resistance

Transmission components requiring dimensional stability under load

Fastener systems benefiting from brass's combination of strength and machinability

Technical Partnership Approach

We provide comprehensive engineering support including:

Design for Manufacturing analysis optimizing components for production efficiency

Material selection guidance based on specific application requirements and environmental regulations

Rapid prototyping services accelerating development cycles and validation testing

Production scaling from initial prototypes to high-volume manufacturing

Quality and Compliance Standards

Our automotive components manufacturing adheres to stringent industry standards:

IATF 16949 quality management system certification

Material traceability throughout the production process

Environmental compliance with RoHS and ELV directives where applicable

Comprehensive documentation supporting customer qualification requirements

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |