- Overview

- Recommended Products

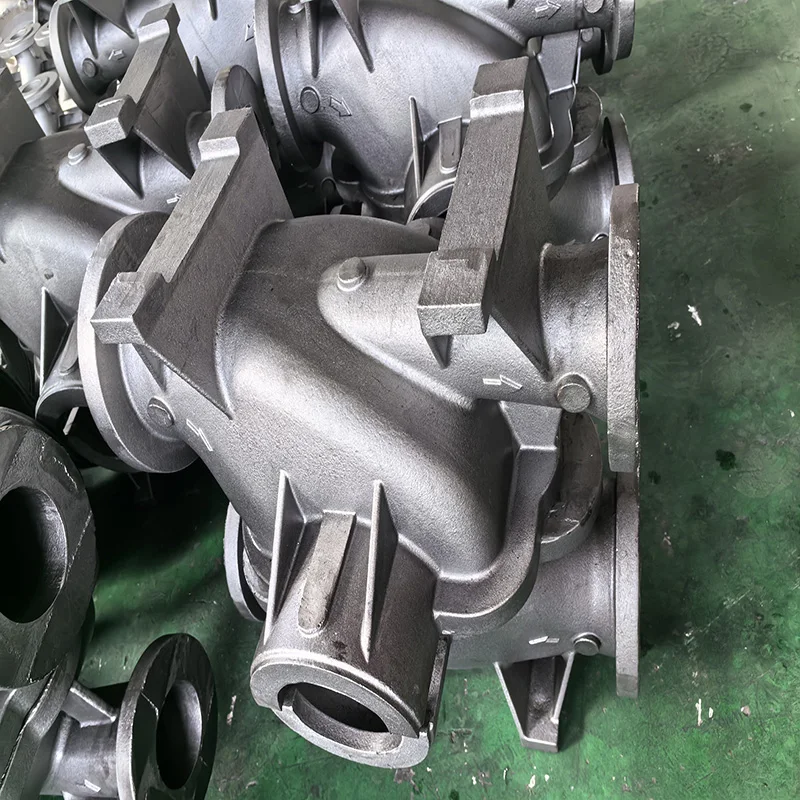

In the realm of precision manufacturing, 4 and 5-axis CNC machining stands as a cornerstone technology for producing complex, high-tolerance brass components. These advanced machining processes, often complemented by quality casting services, deliver unparalleled precision and design flexibility for industries requiring exceptional dimensional accuracy and material performance from brass alloys.

Advanced Brass Material Properties

Brass, an alloy of copper and zinc, is renowned for its excellent mechanical properties and versatility. Known for its distinctive yellow color, brass exhibits exceptional machinability, good wear resistance, and outstanding corrosion resistance in various environments. The material's inherent lubricity reduces friction during machining operations and in final applications, while its electrical and thermal conductivity make it suitable for specialized components. Different brass compositions with varying zinc content (typically 18%-30%) yield distinct characteristics, from red-yellow to brown-yellow hues, allowing for both functional and aesthetic applications.

Precision Machining Capabilities

4-axis CNC machining introduces a rotational axis (typically the A-axis) beyond the standard XYZ linear movements, enabling more complex operations like precision drilling and contouring on multiple faces without repositioning. This capability significantly enhances production efficiency and accuracy compared to conventional 3-axis machining.

5-axis CNC machining represents the pinnacle of machining technology, incorporating two additional rotational axes (commonly A and B, or A and C axes). This configuration allows for simultaneous machining from virtually any direction, enabling the creation of highly complex geometries with exceptional precision. The continuous 5-axis machining capability ensures the cutting tool maintains optimal orientation to the workpiece surface, delivering superior surface finishes and accessing hard-to-reach part features.

Integrated Manufacturing Processes

The manufacturing process for brass components often integrates both casting and machining technologies. Initial casting processes create near-net-shape components, which are then precision-finished using advanced CNC equipment. Modern CNC machining centers feature high-speed spindles (reaching up to 16,000 rpm) and rapid tool-changing systems (under one second), maximizing efficiency and maintaining competitive production cycles.

Twin-pallet loading systems and online probing further enhance productivity by allowing uninterrupted operation and in-process quality verification. For brass components requiring extreme precision, multi-axis CNC lathes with Y-axis, C-axis, driven tools, and sub-spindle capabilities provide complete machining solutions in single setups.

Performance Advantages and Quality Assurance

Brass components manufactured through these advanced processes deliver:

Excellent dimensional stability with tolerances reaching ±0.01mm

Superior surface finishes achieving Ra 0.1-3.2 through optimized machining parameters

Enhanced mechanical properties through controlled material processing

Consistent quality through rigorous inspection protocols including CMM verification

Quality assurance is maintained through comprehensive inspection methodologies utilizing coordinate measuring machines (CMM), optical comparators, and specialized gauging systems. This ensures every brass component meets specified dimensional requirements and quality standards.

Comprehensive Application Range

The combination of brass material properties and advanced machining capabilities serves numerous industries:

Plumbing and Fluid Handling: Valve bodies, pipe fittings, and connector components leveraging brass's corrosion resistance

Electrical and Electronics: Connectors, terminals, and components utilizing brass's electrical conductivity

Marine Applications: Corrosion-resistant components for shipbuilding and offshore installations

Architectural Elements: Decorative hardware, fixtures, and architectural details benefiting from brass's aesthetic appeal

Industrial Machinery: Gears, bearings, and bushings capitalizing on brass's durability and low friction

Technical Partnership Approach

Progressive manufacturers offer comprehensive engineering support including:

Design for Manufacturing analysis optimizing components for both performance and production efficiency

Material selection guidance for specific application requirements

Rapid prototyping services accelerating product development cycles

Production scaling from prototype quantities to full production volumes

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |