- Overview

- Recommended Products

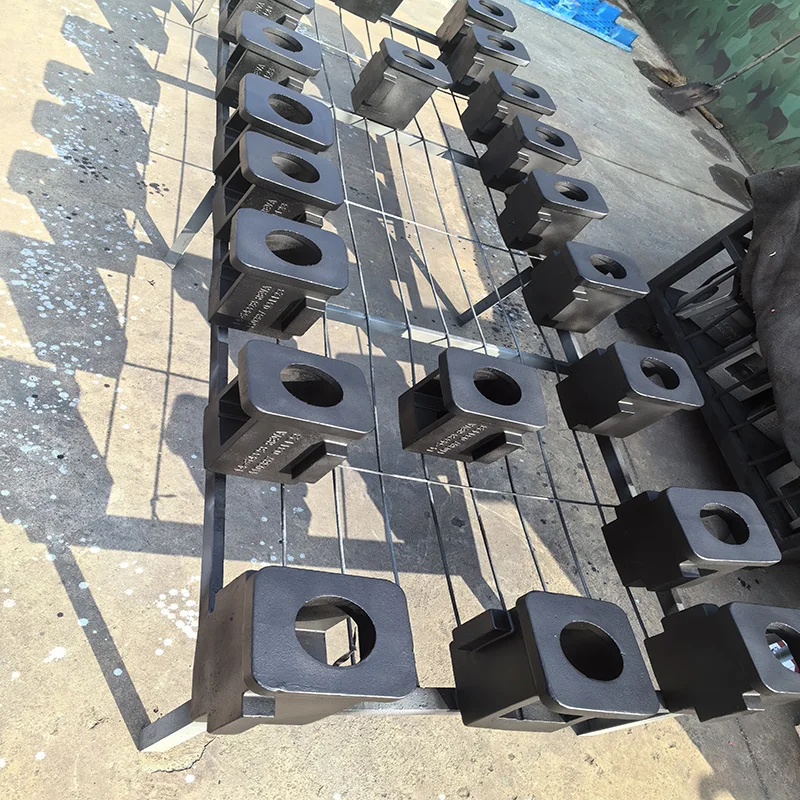

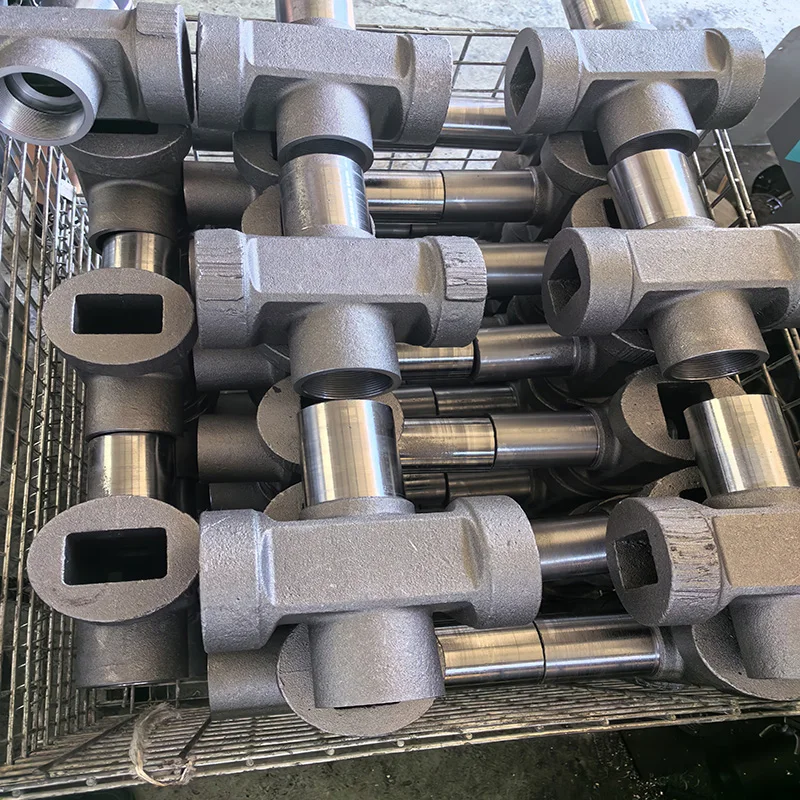

Our manufacturing facility specializes in producing high-quality, economical cast iron components through advanced sand casting processes. We provide comprehensive casting services for both grey iron and ductile iron parts, delivering exceptional value without compromising on mechanical performance or dimensional accuracy.

Superior Material Properties

Grey Iron Characteristics

Our grey iron castings (Grades G2500-G4000) leverage the natural graphite flake structure that provides:

Excellent vibration damping capacity superior to most engineering materials

Outstanding wear resistance with hardness ranging from 187-277 Brinell

Good machinability allowing high-speed processing with minimal tool wear

Natural lubricity from graphite flakes reducing friction in moving applications

Thermal conductivity ideal for components subjected to thermal cycling

Ductile Iron Advantages

Our ductile iron castings (Grades 60-40-18 to 120-90-02) offer enhanced mechanical properties through nodular graphite formation:

Superior tensile strength from 60,000 to 120,000 psi

Exceptional impact resistance with elongation ranging from 18% to 2%

Improved fatigue strength for dynamic load applications

Excellent corrosion resistance comparable to carbon steels

Good low-temperature toughness maintaining properties at sub-zero temperatures

Advanced Sand Casting Technology

Our automated sand casting systems incorporate modern foundry technology to deliver consistent quality at competitive prices:

Molding Processes

Green sand molding using bonded silica sand for cost-effective production

Resin sand systems for improved dimensional accuracy and surface finish

Automatic molding lines producing up to 120 molds per hour

Precision pattern equipment ensuring repeatable casting dimensions

Melting and Pouring

Electric induction furnaces maintaining precise temperature control

Computerized pouring systems ensuring consistent metal quality

Real-time metallurgical analysis verifying chemical composition

Controlled cooling cycles optimizing microstructure development

Cost-Effective Production Advantages

Our manufacturing approach delivers significant cost savings through:

High-volume production capabilities reducing per-part costs

Optimized gating systems minimizing material waste

Energy-efficient melting operations lowering utility expenses

Automated processing reducing labor requirements

Local material sourcing minimizing supply chain costs

Quality Assurance and Compliance

Despite our competitive pricing, we maintain rigorous quality standards:

Material certification to ASTM A48 (Grey Iron) and ASTM A536 (Ductile Iron)

Dimensional inspection using manual and automated measurement systems

Surface quality control maintaining finish requirements of 250-500 microinches

Non-destructive testing including liquid penetrant and magnetic particle inspection

Mechanical testing verifying hardness, tensile strength, and microstructure

Comprehensive Application Range

Our cost-effective cast iron components serve numerous industries:

Automotive and Transportation

Brake components and suspension parts

Engine brackets and transmission cases

Exhaust manifolds and turbocharger housings

Industrial Machinery

Pump housings and valve bodies

Gear blanks and machinery bases

Hydraulic components and compressor parts

Construction and Agriculture

Tractor components and implement parts

Construction hardware and structural elements

Drainage parts and municipal castings

General Manufacturing

Machine tool components and equipment bases

Press frames and structural supports

Industrial wheels and pulley systems

Value-Added Services

We enhance our casting services with comprehensive secondary operations:

Precision machining of critical dimensions and mounting surfaces

Surface treatments including painting, plating, and powder coating

Heat treatment processes for enhanced mechanical properties

Assembly operations incorporating multiple components

Just-in-time delivery supporting lean manufacturing initiatives

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |